FAQs

Jonathan Schwartz

(repair and general laser questions)

americanlaserco@gmail.com

213-797-0728 (direct line)

ext 1 on main line

Shop Address

1319 s Los Angeles st

LA, CA 90015

Jessica Schwartz

(DIY laser cutting and ongoing jobs)

americanlaserco@gmail.com

323-380-4757 (direct line)

ext 2 main line

Mailing address

4841 Bonvue Ave

La, CA 90027

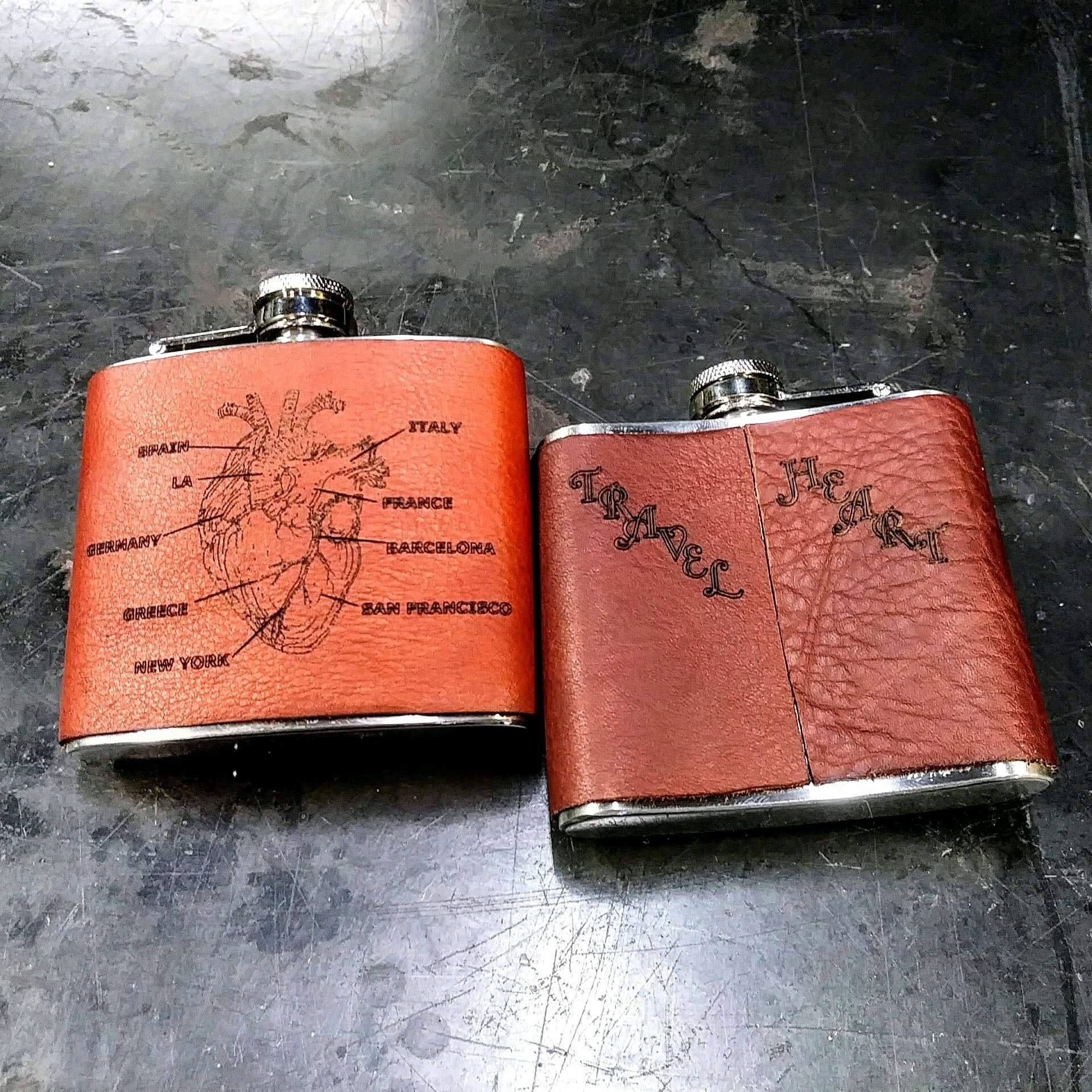

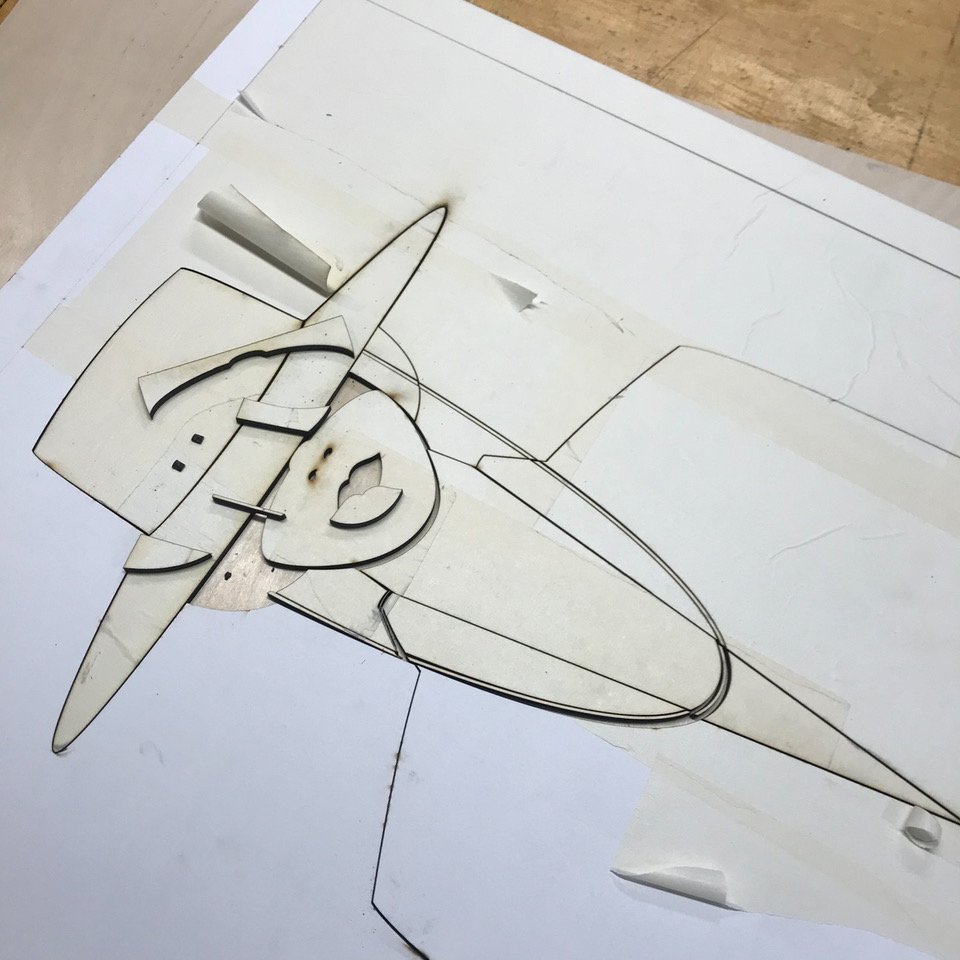

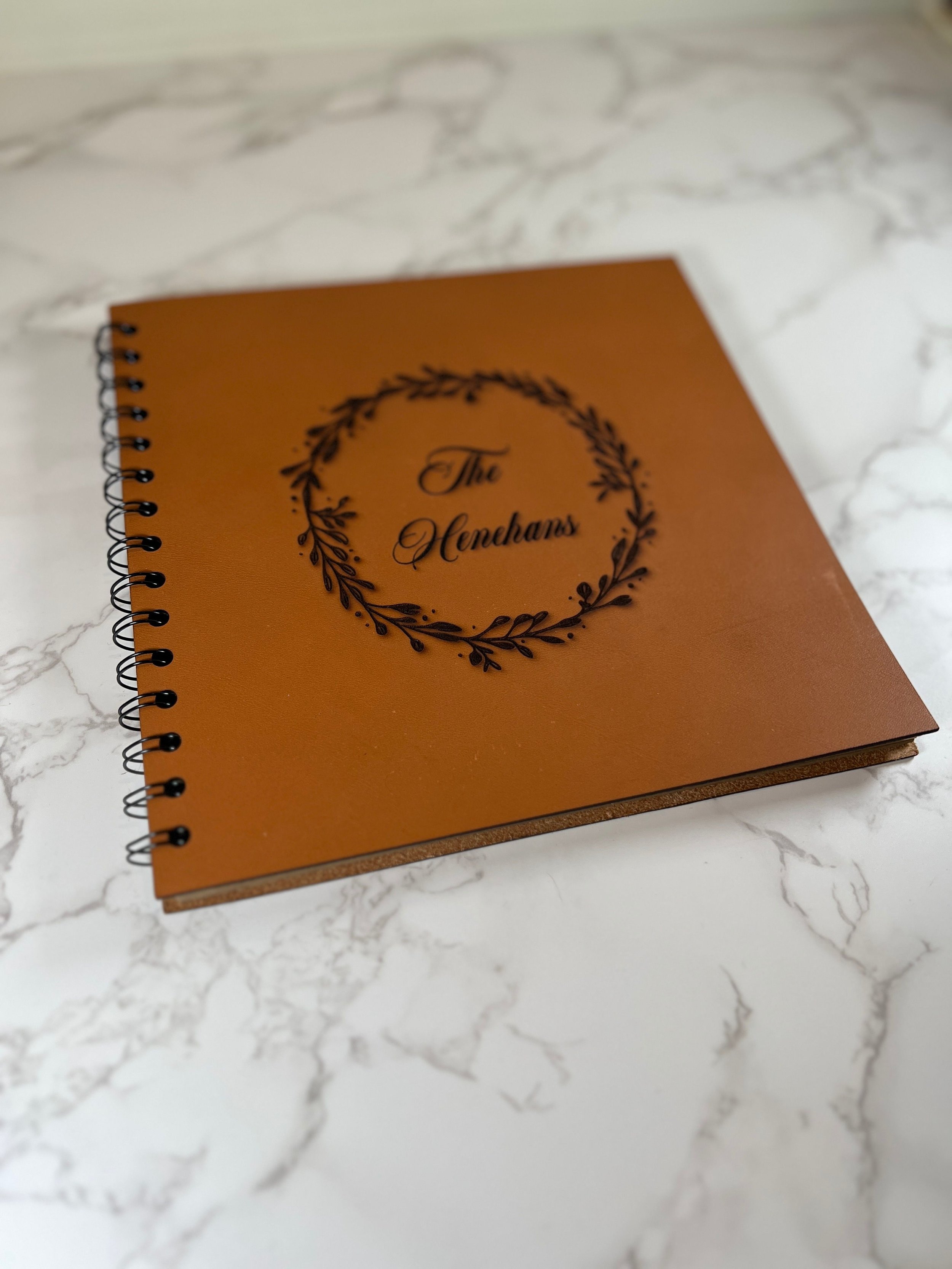

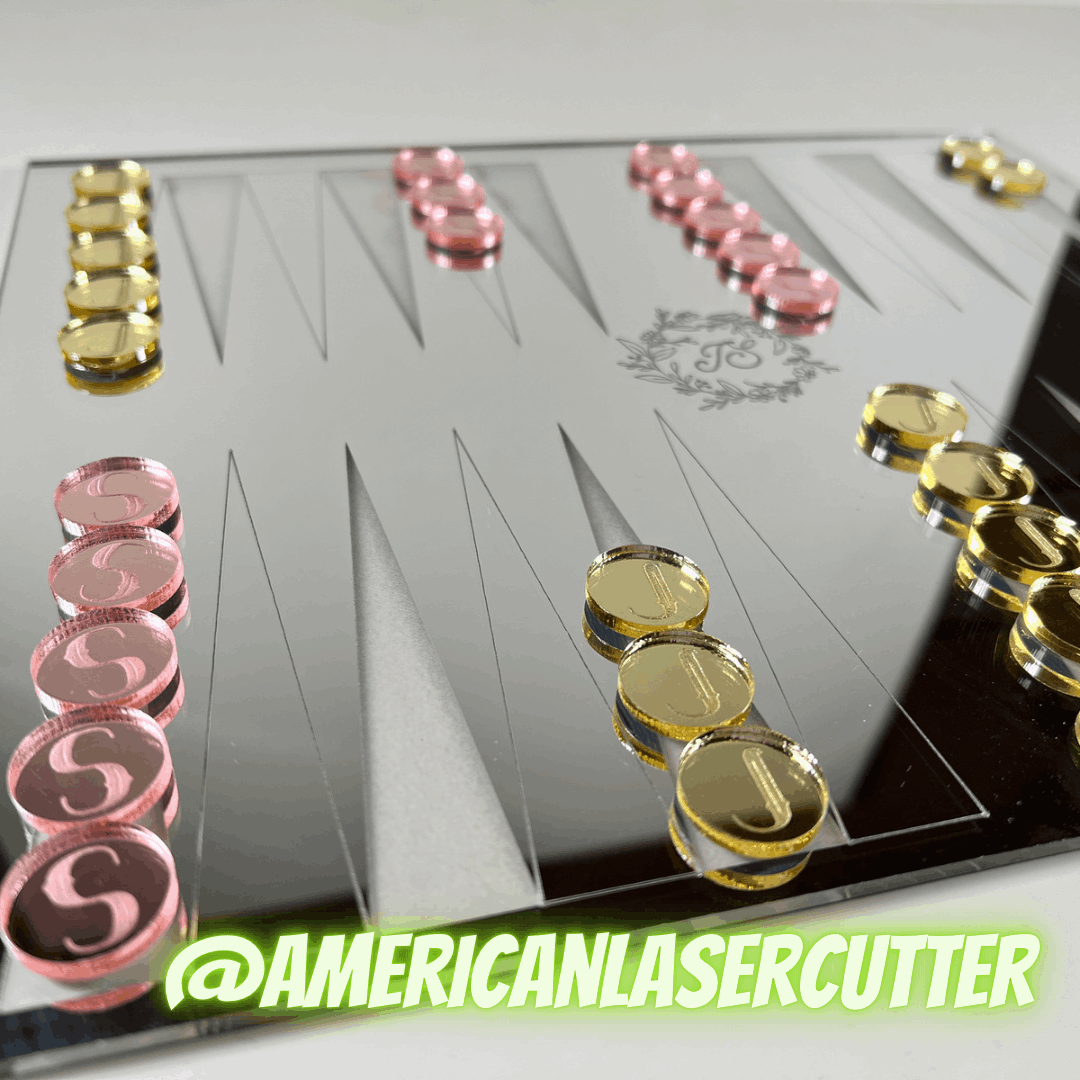

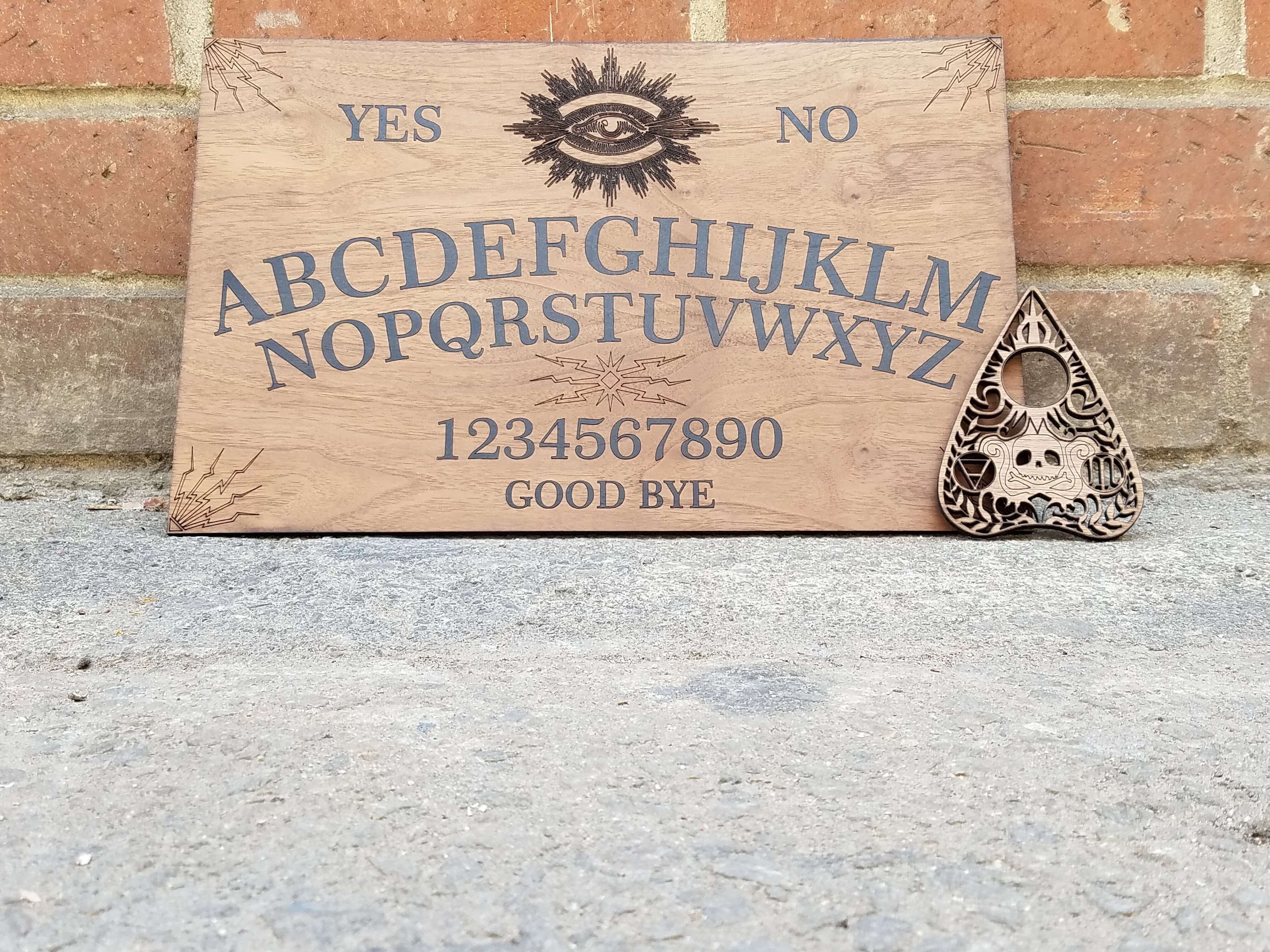

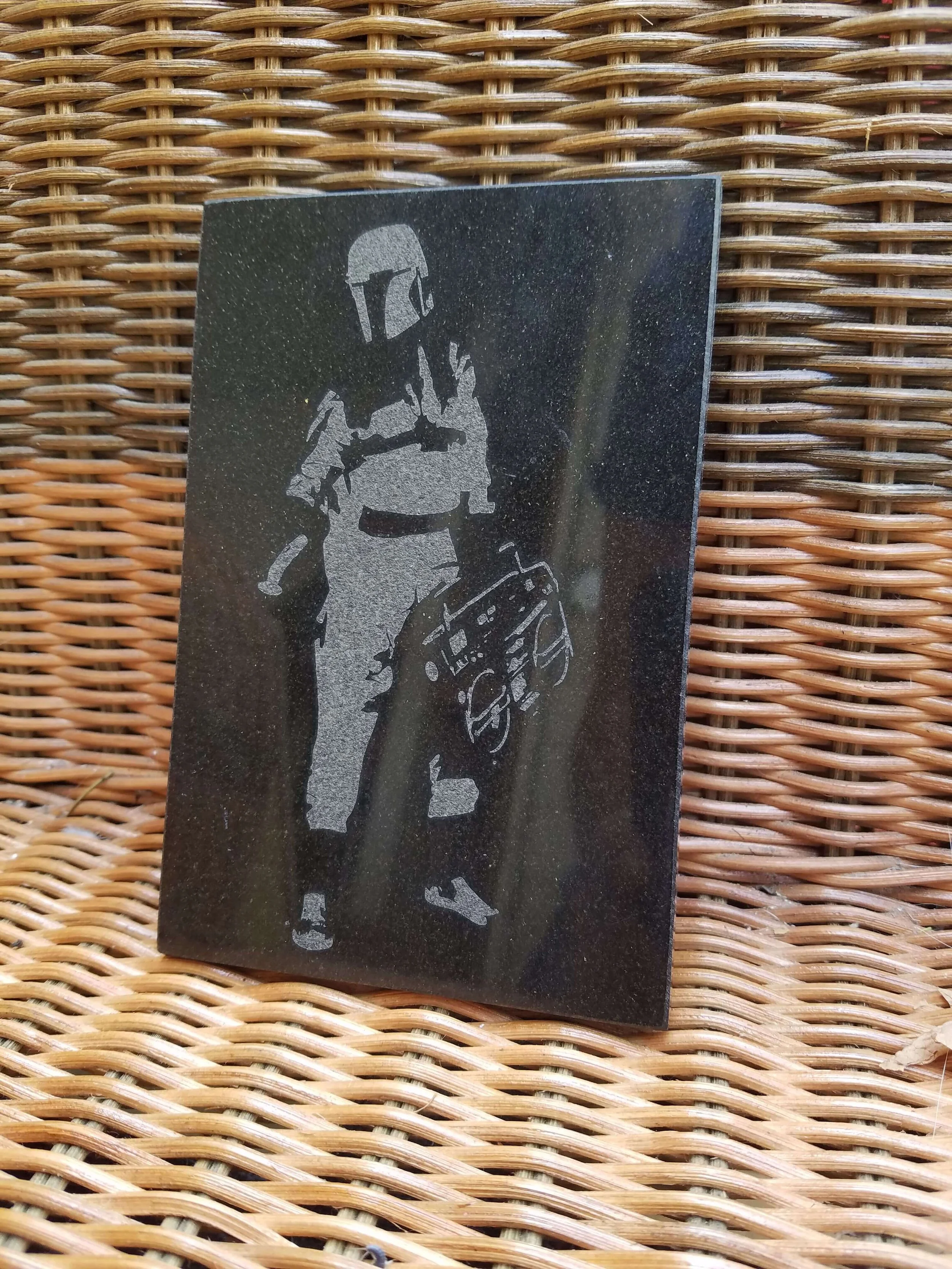

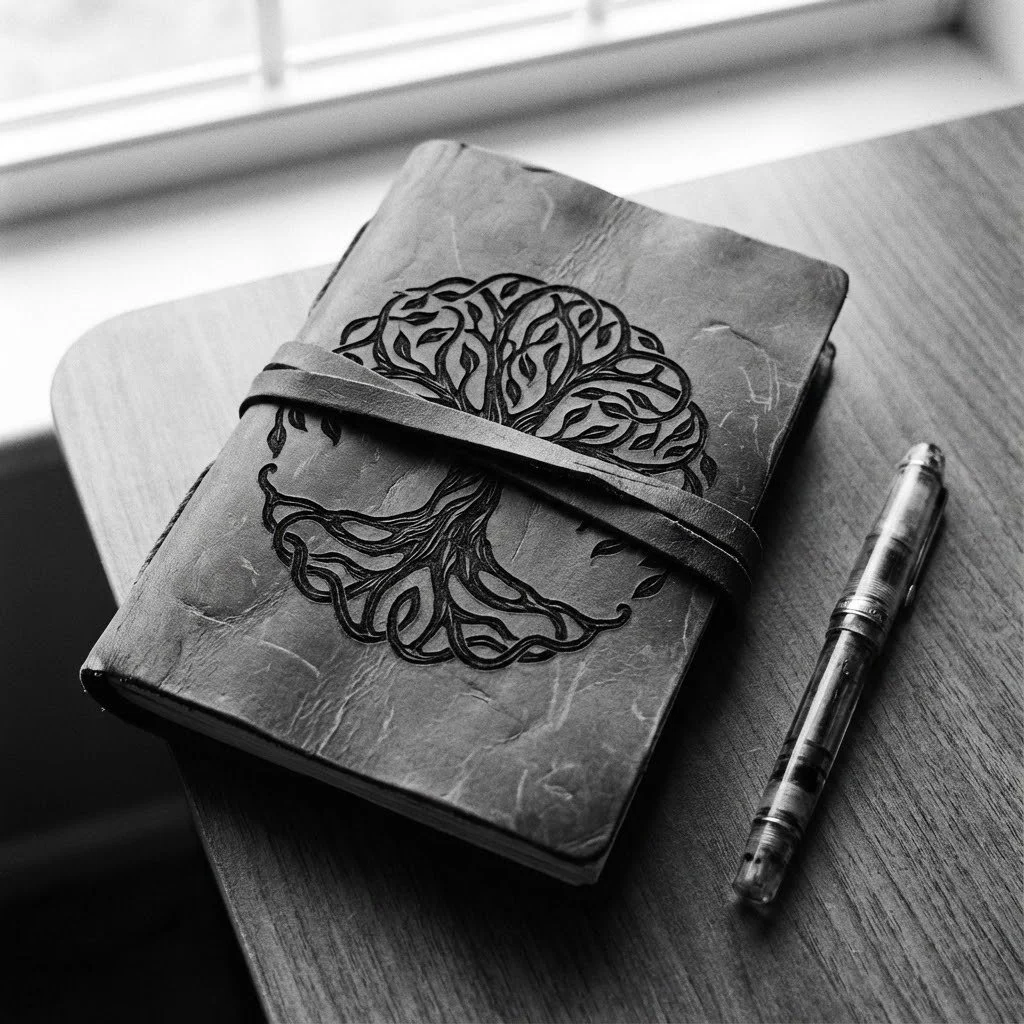

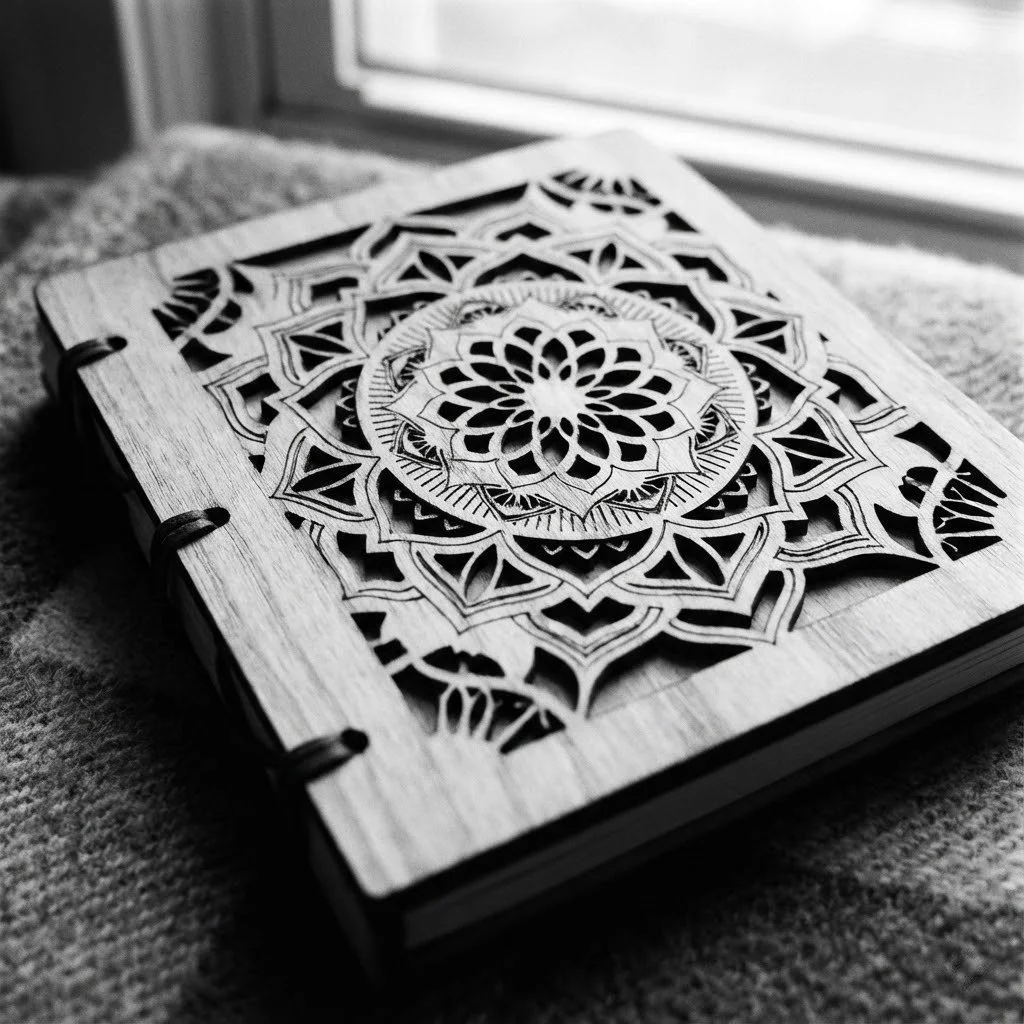

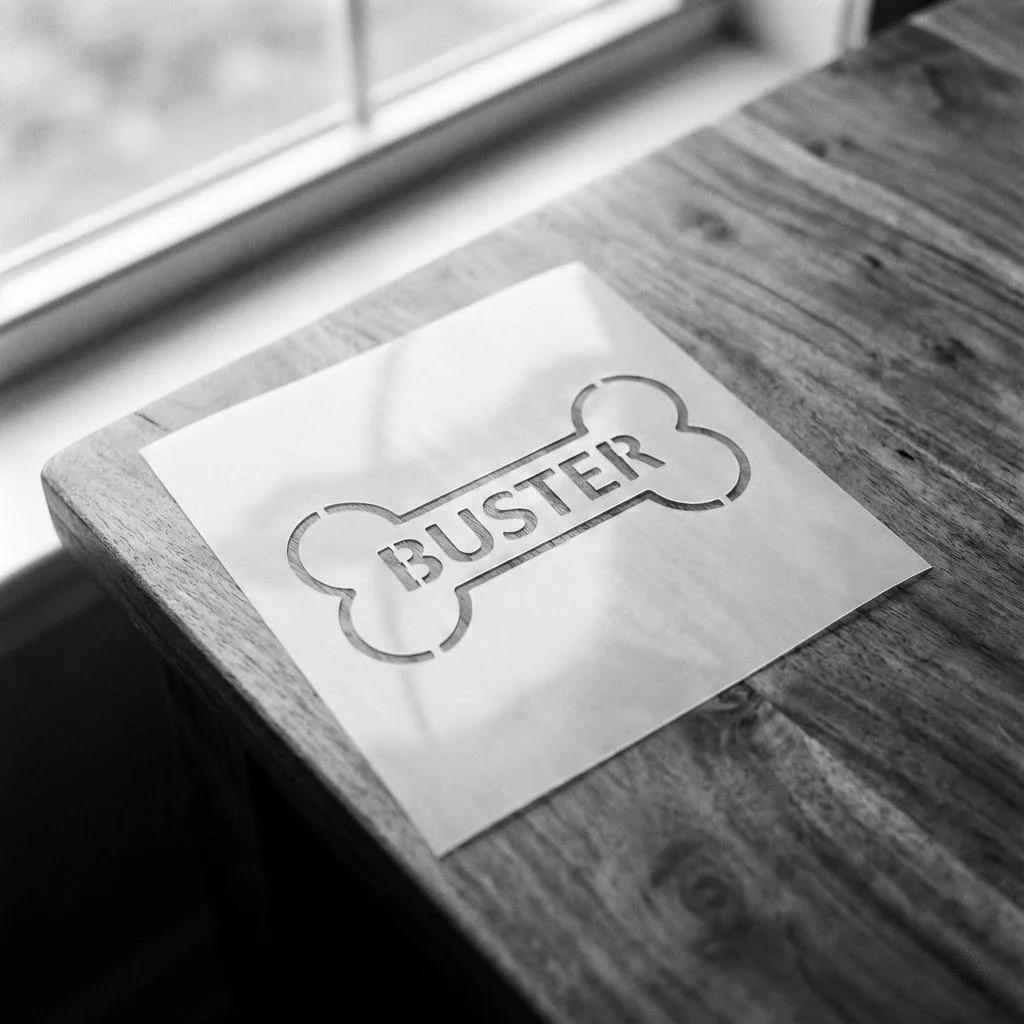

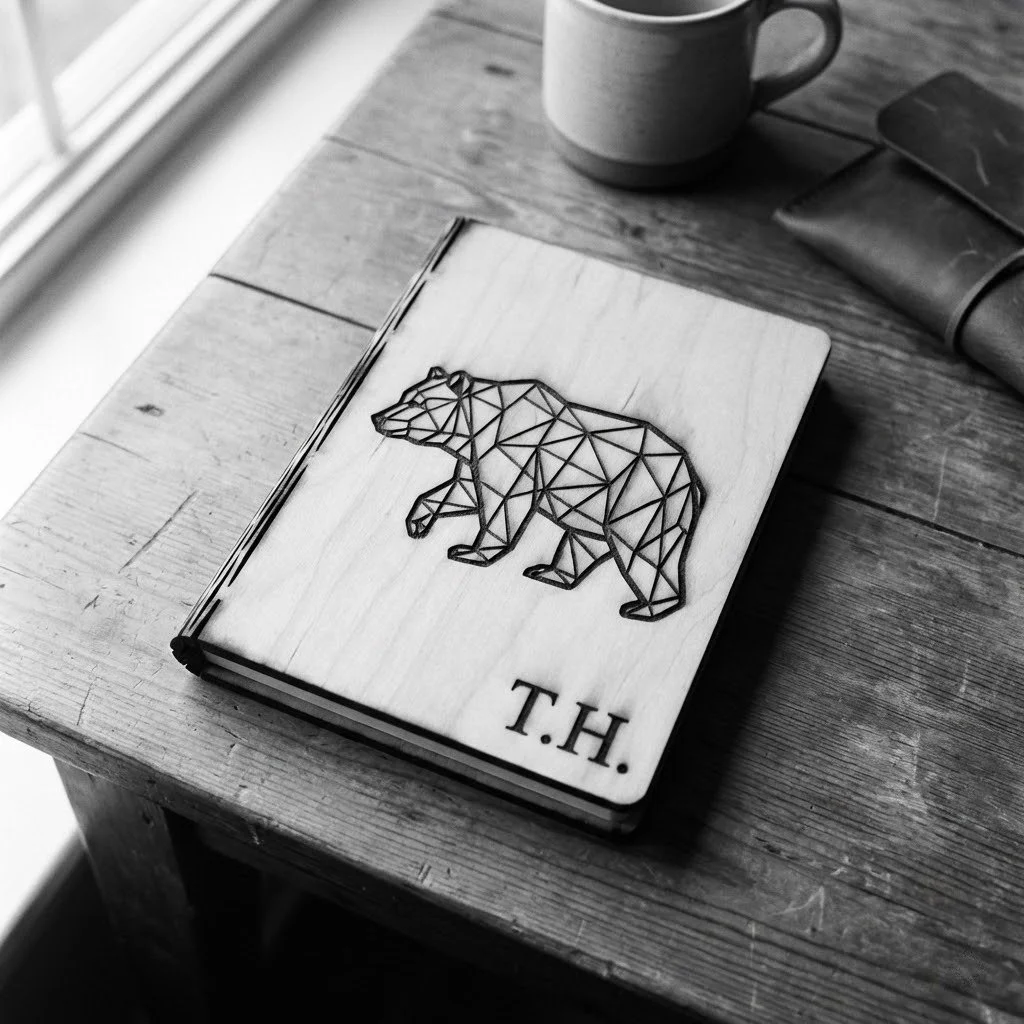

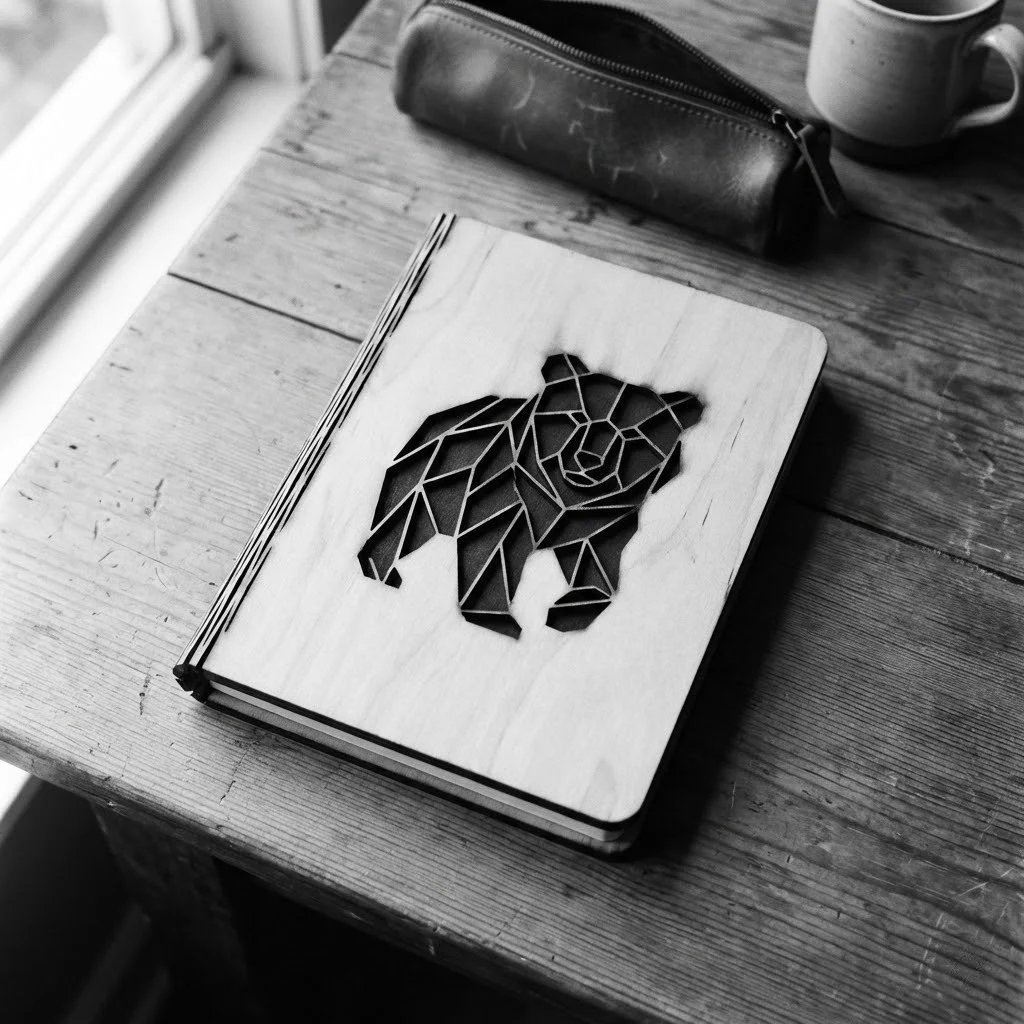

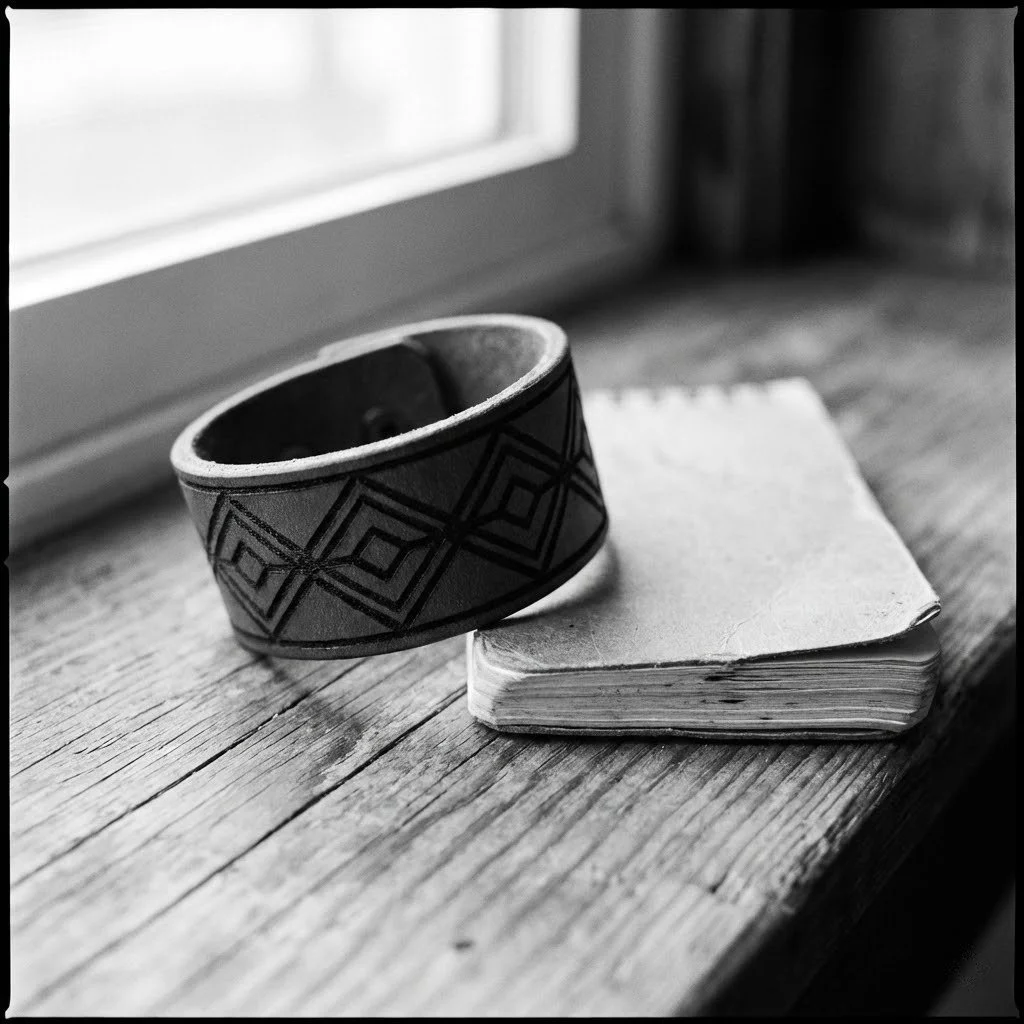

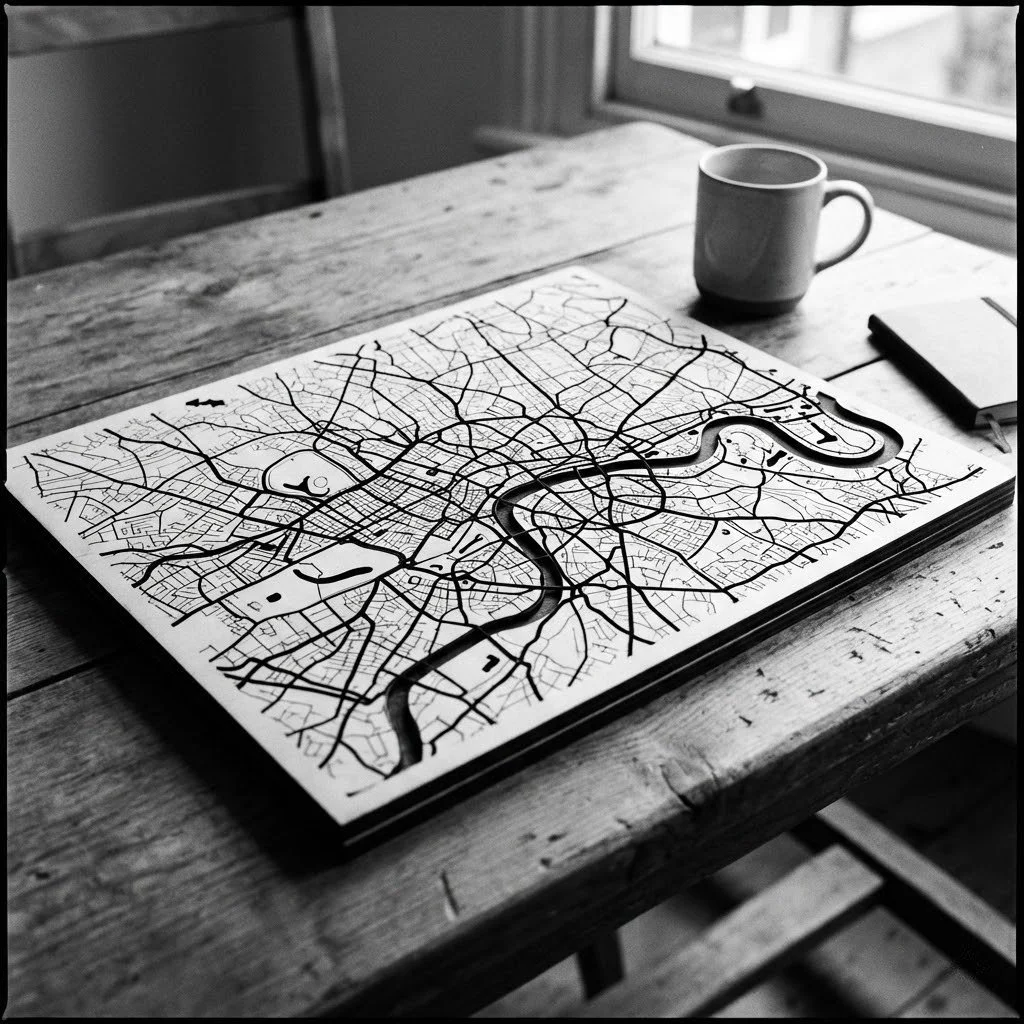

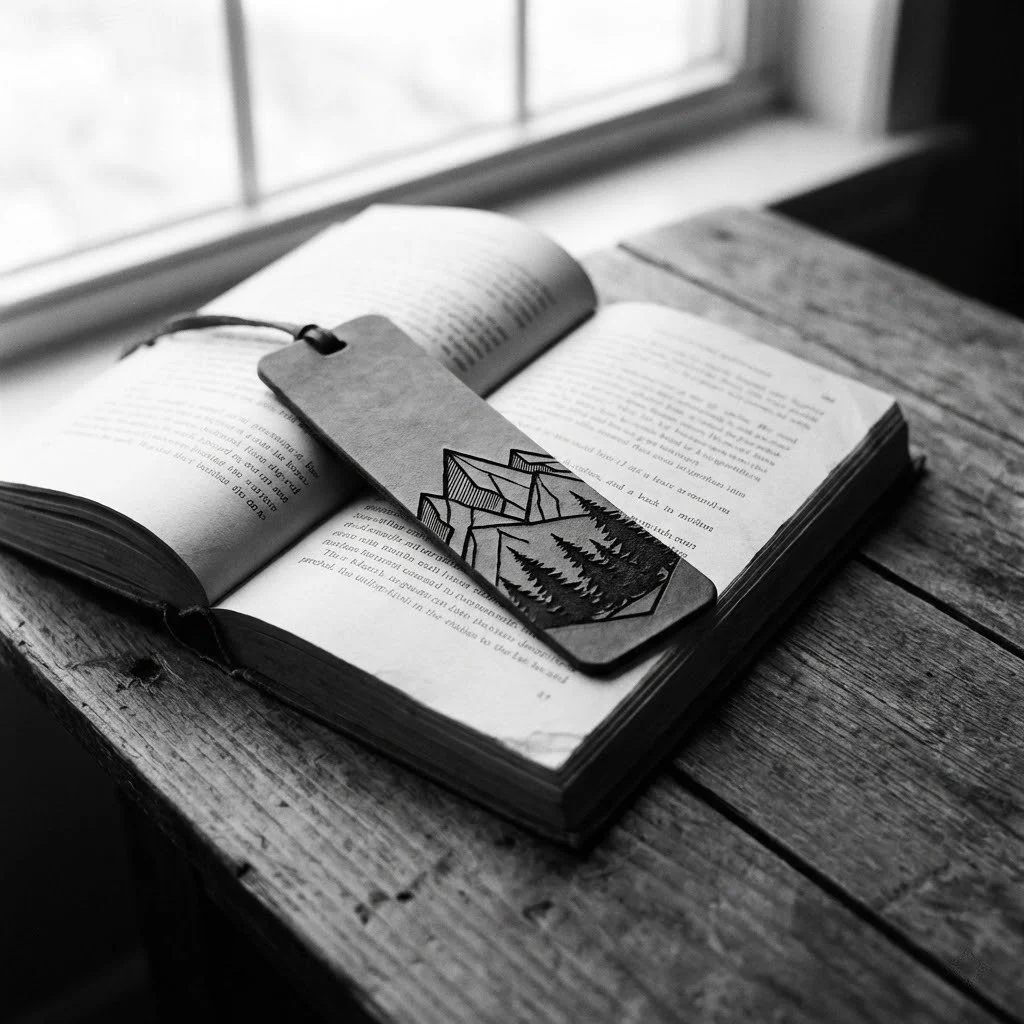

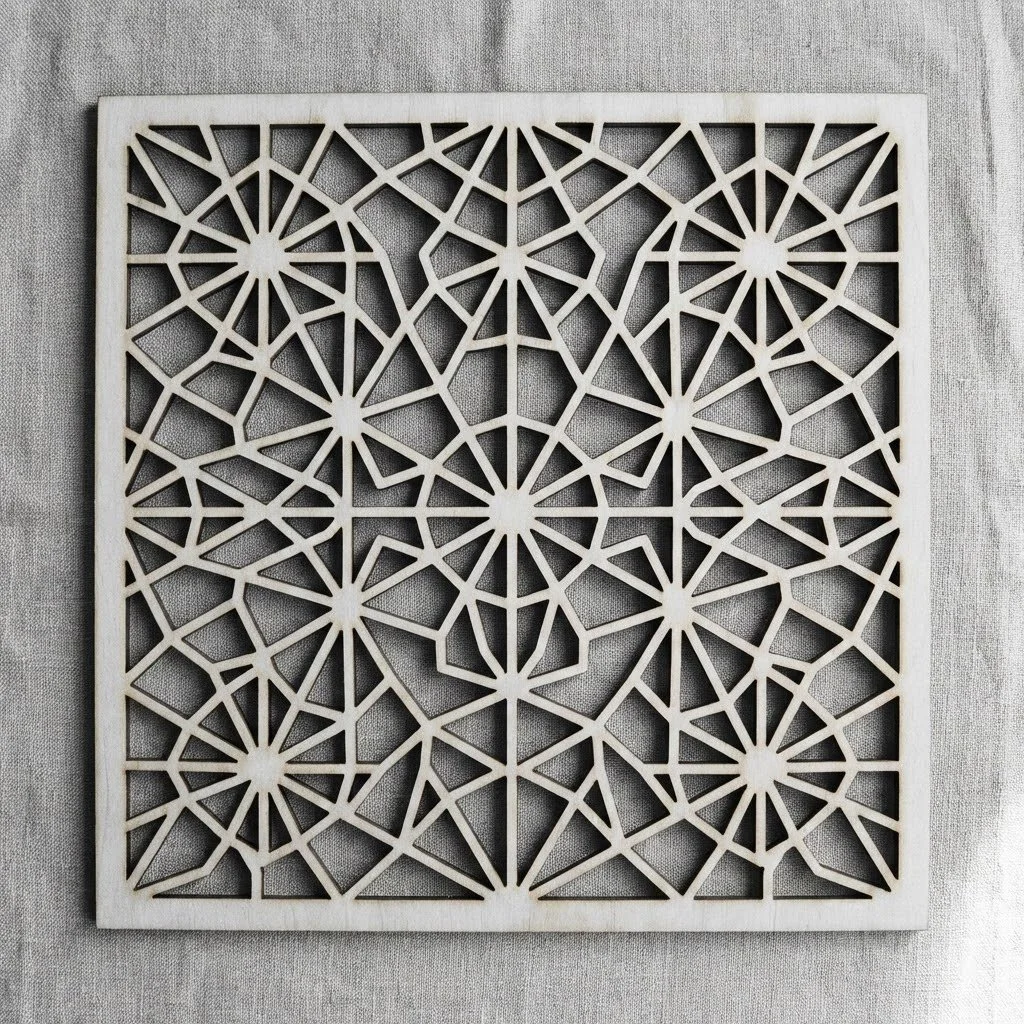

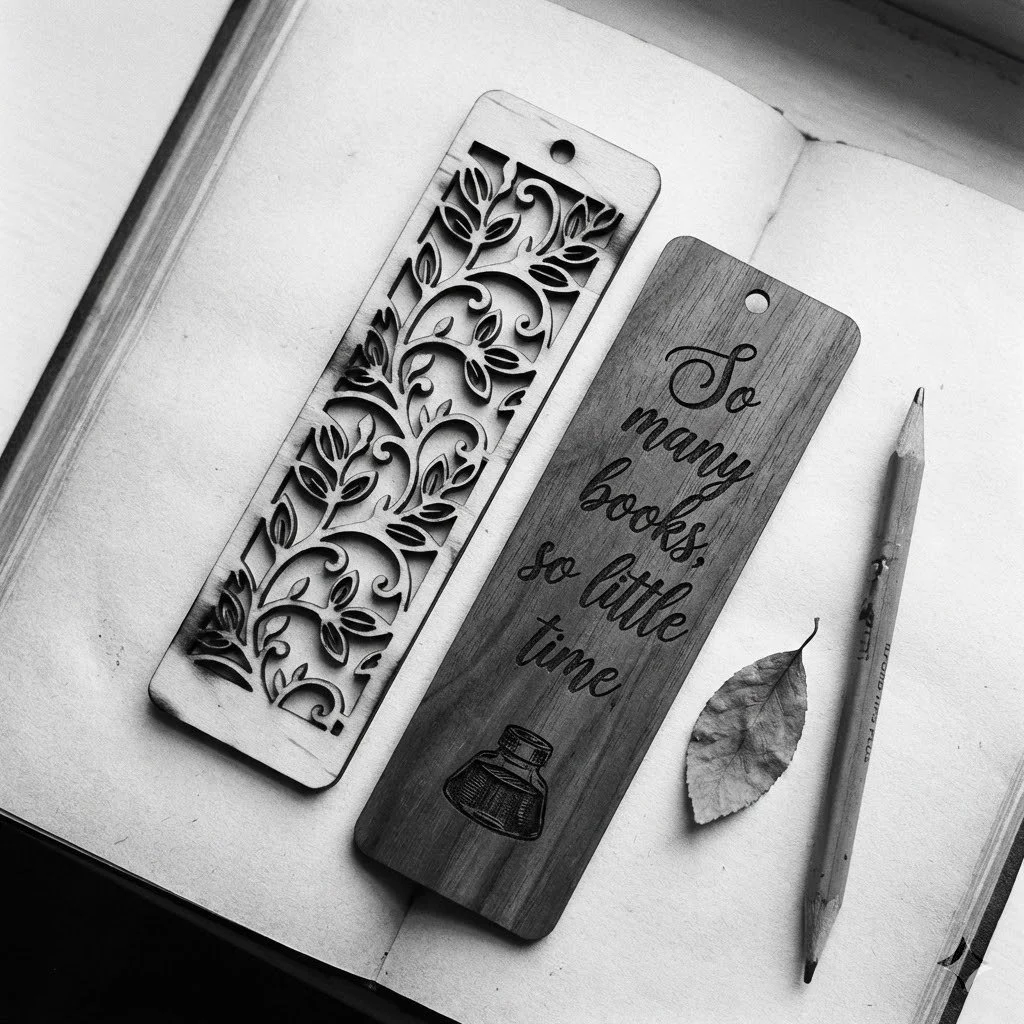

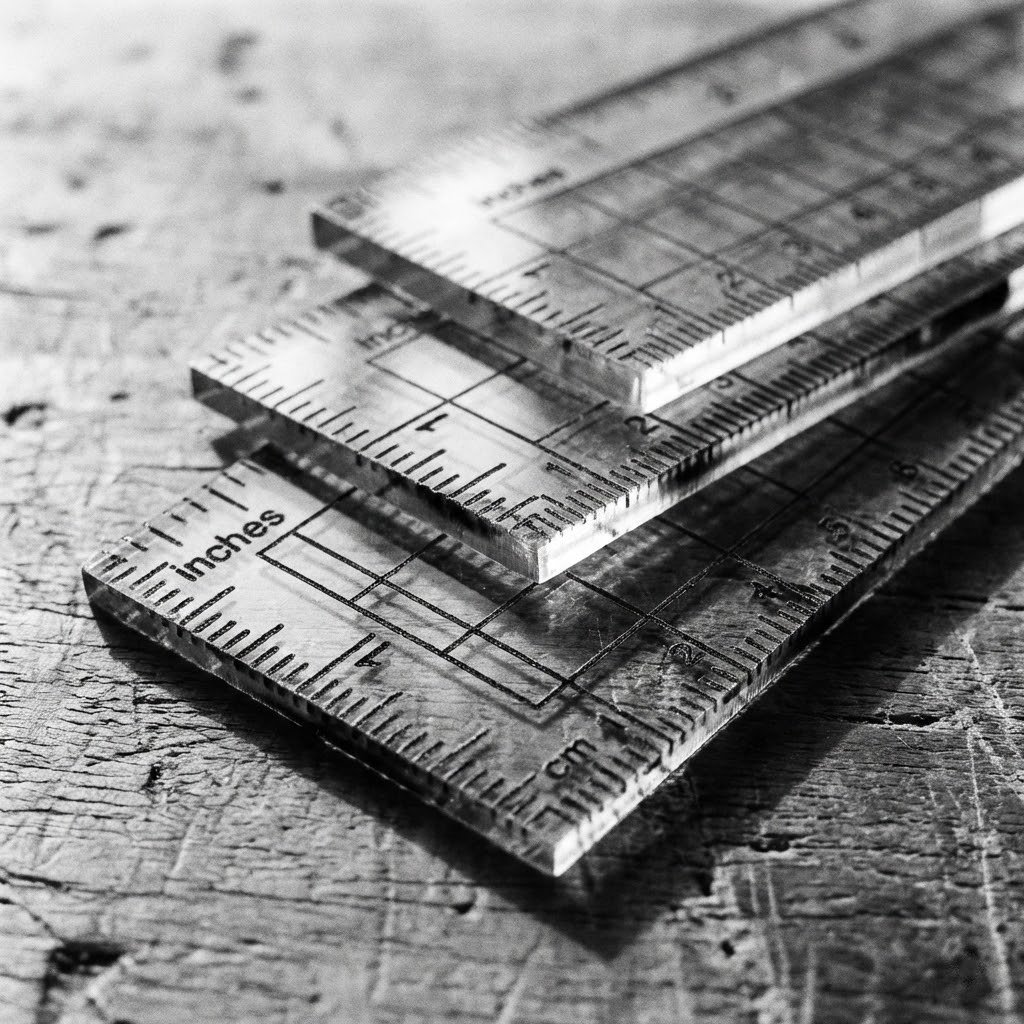

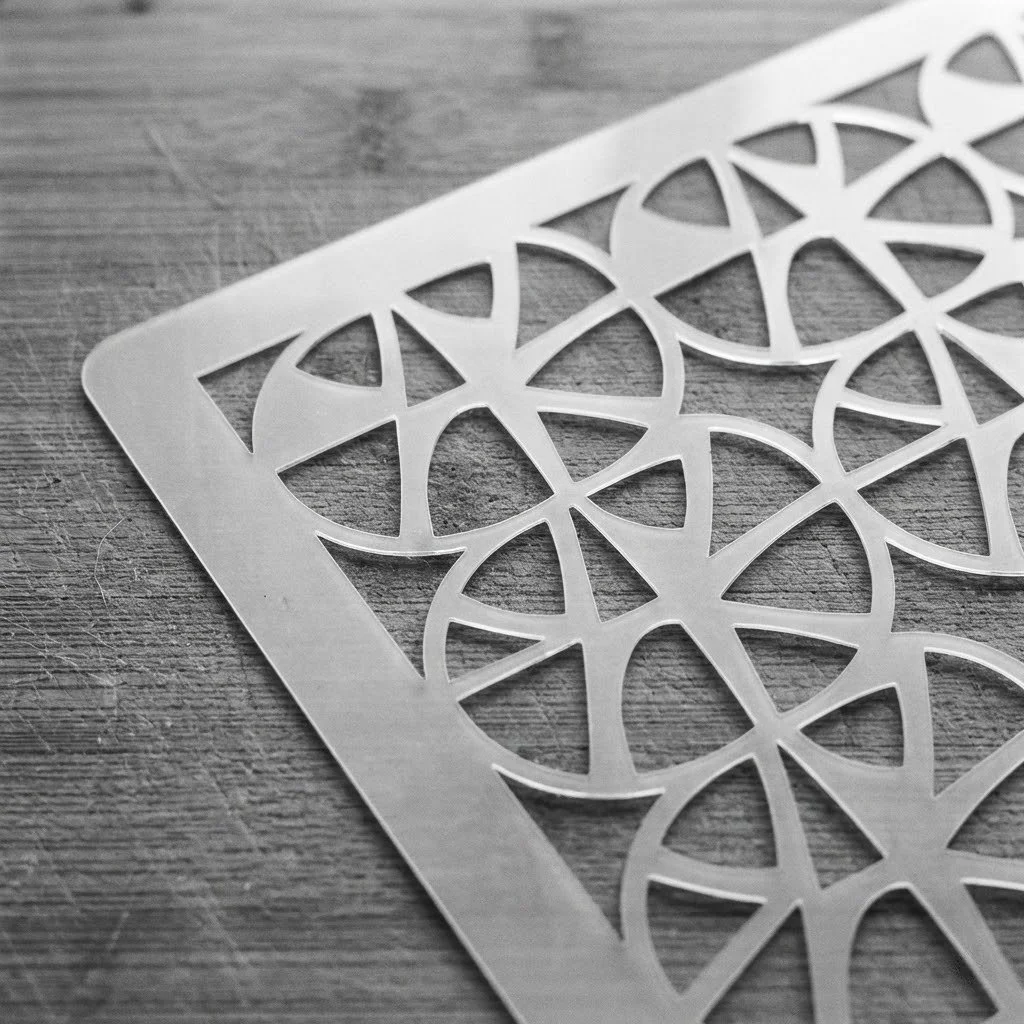

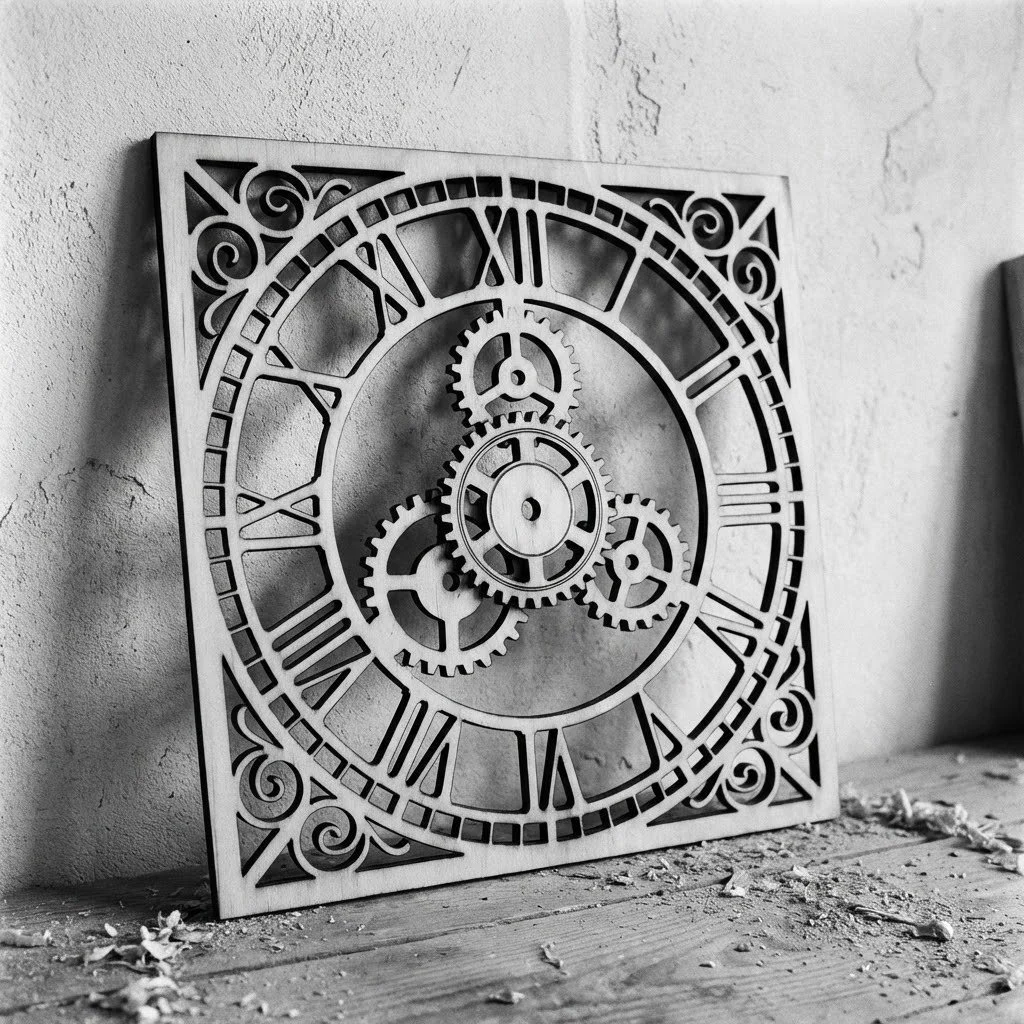

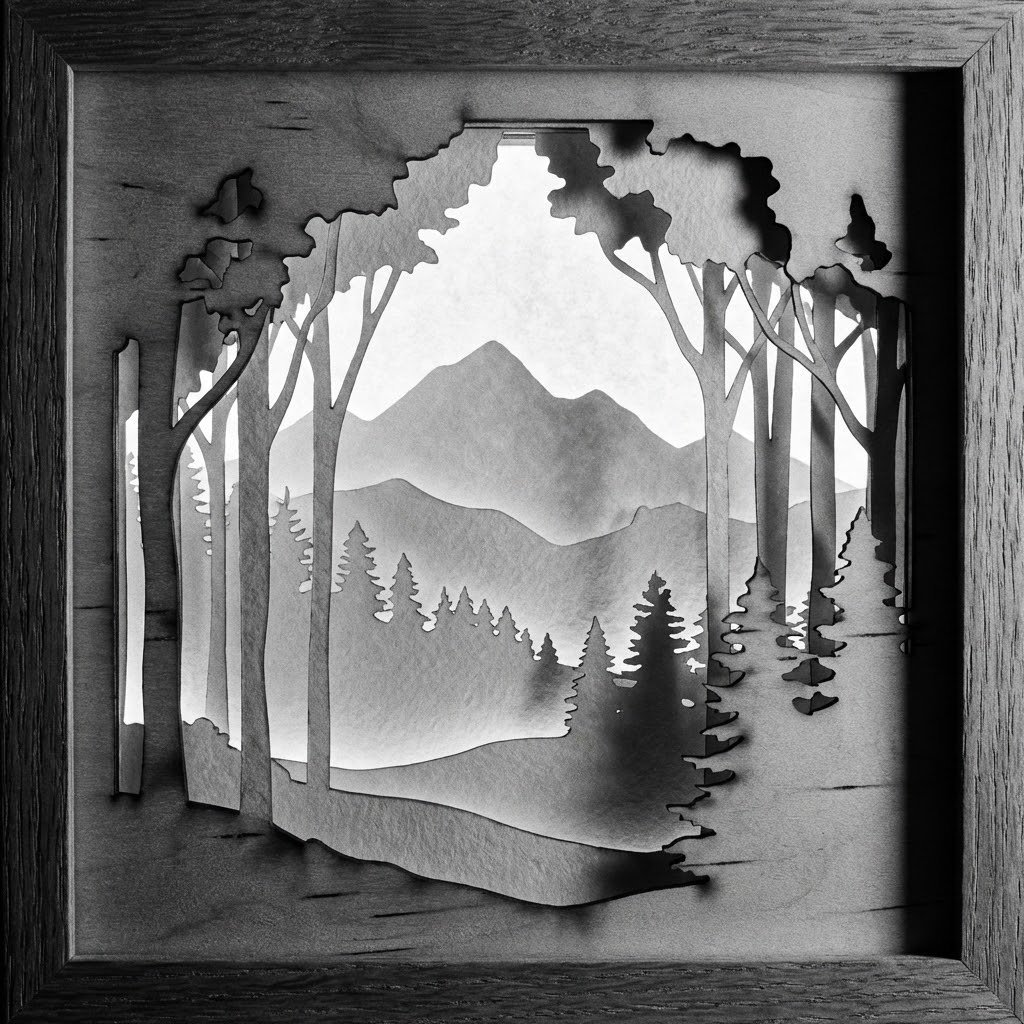

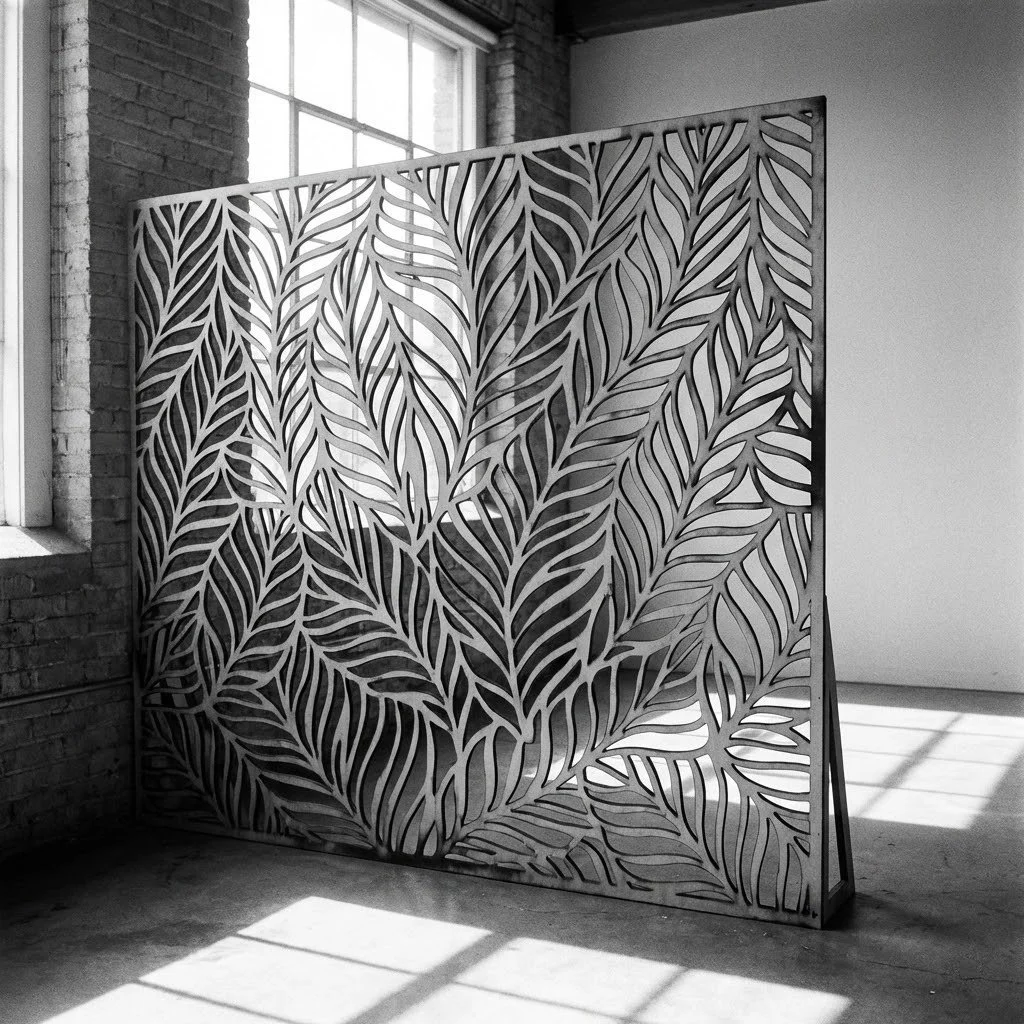

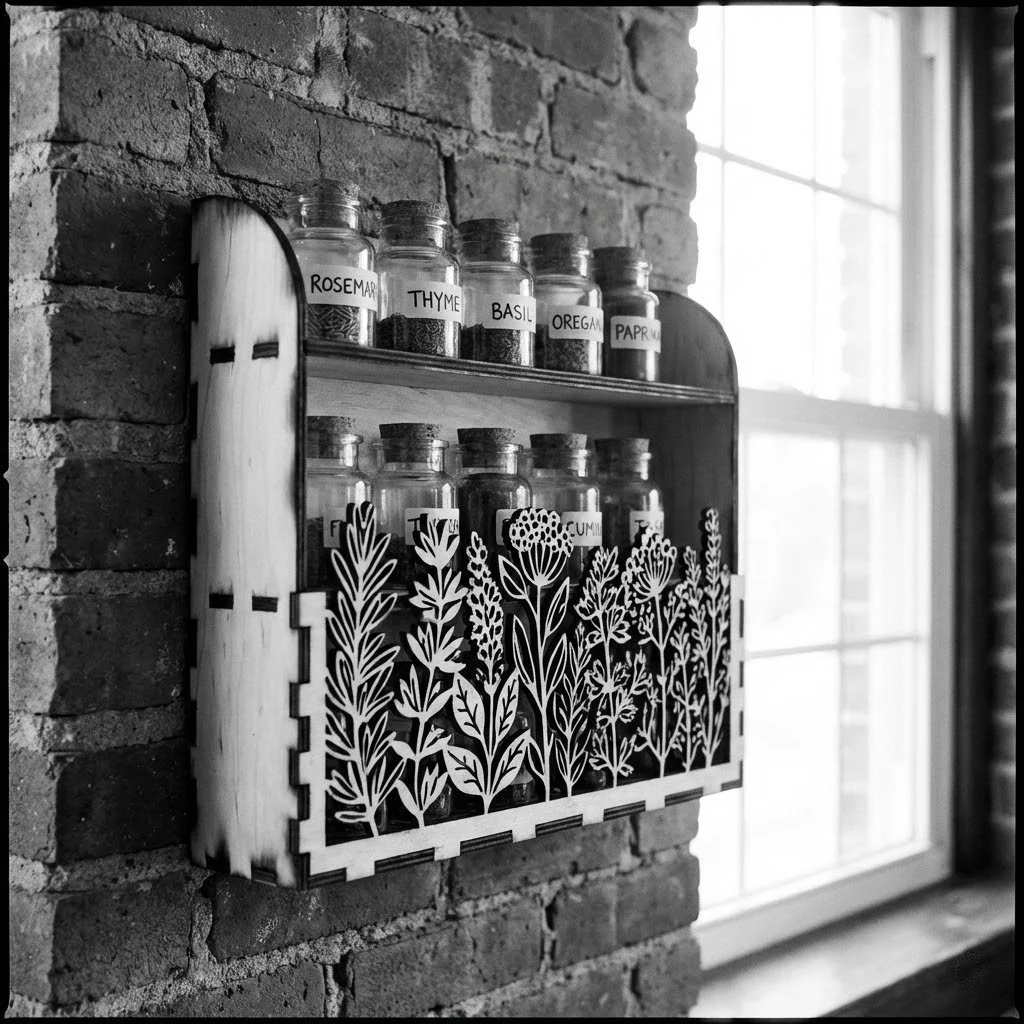

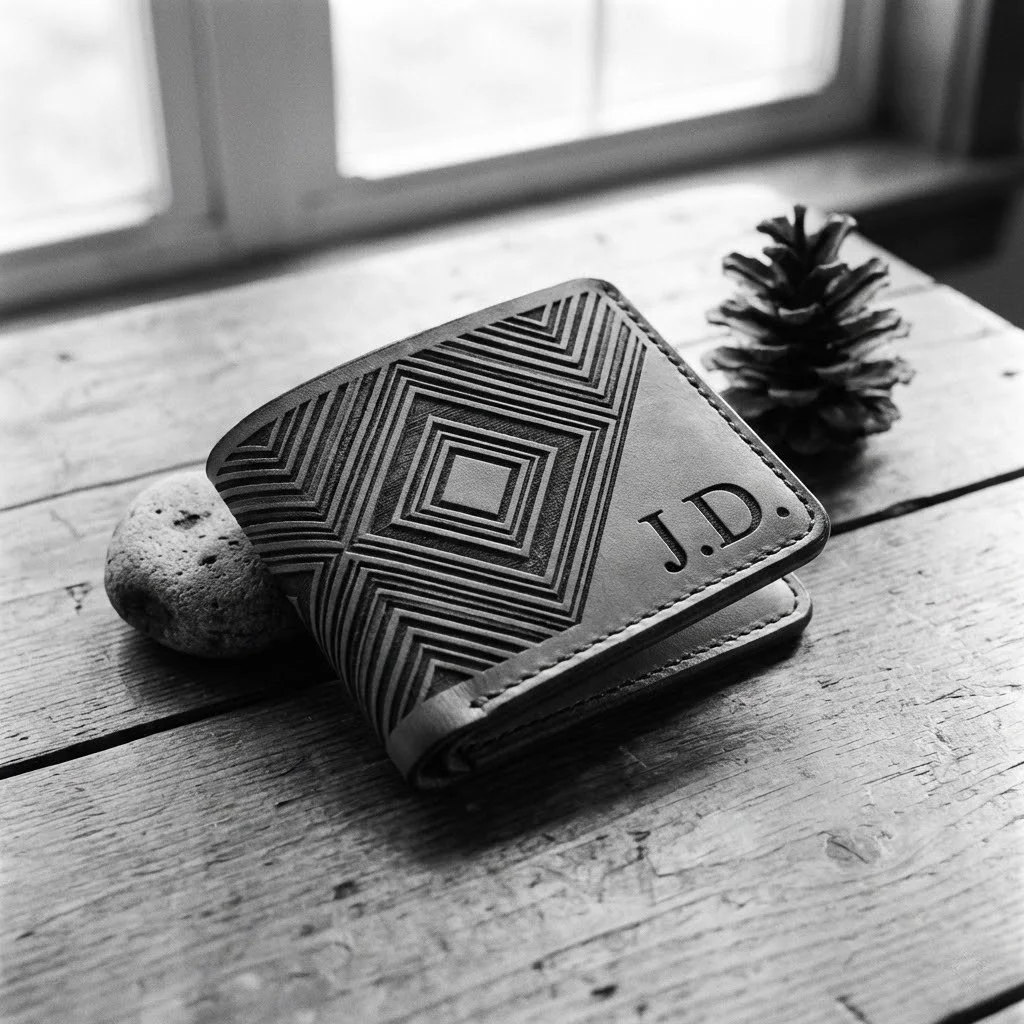

laser project photo examples

A Cutting-Edge Legacy: The History of American Laser Cutter

American Laser Cutter, based in Los Angeles, offers a comprehensive suite of laser cutting solutions tailored for both individuals and businesses. We distinguish ourselves through a unique blend of accessibility, expertise, and advanced technology. Complementing this, we provide professional laser cutting, engraving, etching, and scoring services for those preferring a hands-off approach or requiring large-scale production, guaranteeing fast turnaround times. We specialize in a wide array of materials such as wood, acrylic (including 1/2 inch thick acrylic), fabric, leather, paper, cardboard, and foam, and even stock common plexiglass and plywood for client convenience. Beyond direct cutting, American Laser Cutter is a true laser hub, offering courses available remotely or on-site, to empower users with software mastery and material knowledge. We also provide laser cutter repair and maintenance services, leveraging over a decade of experience to support clients with our machines, ensuring consistent operation and offering valuable technical support.

FAQs

Here are 10 Frequently Asked Questions (FAQs) and their answers for American Laser Cutter, covering their services, DIY options, and repair expertise, tailored for clients in Los Angeles.

American Laser Cutter: Top 10 Frequently Asked Questions (FAQs)

1. What services does American Laser Cutter offer?

Answer: American Laser Cutter provides a comprehensive range of laser fabrication solutions. Our primary services include custom laser cutting and engraving for a wide variety of materials. We also offer DIY (Do-It-Yourself) laser cutter rentals for those who prefer hands-on operation, and a specialized CO2 laser cutter repair service for machines experiencing issues. We aim to be your one-stop shop for all laser-related needs in Los Angeles.

2. What materials can you laser cut or engrave?

Answer: We specialize in processing a diverse array of non-metal materials with our CO2 lasers. Common materials include:

Woods: Plywood, MDF, solid wood (e.g., Baltic Birch, walnut, maple, cherry, balsa, basswood).

Acrylics/Plastics: Cast and extruded acrylic (Plexiglas), Mylar.

Fabrics & Leathers: Cotton, felt, denim, silk, genuine leather, some faux leather.

Paper Products: Cardboard, mat board, cardstock, bristol board.

Other: Rubber, cork, EVA foam, certain foams, anodized aluminum (for engraving). We can engrave on some metals with a specialized coating or direct marking. If you have a unique material, please contact us for a material test.

3. How do I get a quote for a custom laser cutting project?

Answer: To get an accurate quote, please visit our "Get A Quote" section on our website or contact us directly. We'll typically need your design file (preferably in vector format like .AI, .DXF, or PDF), the material type and thickness you plan to use, the desired quantity, and any specific finishing requirements. The more details you provide, the faster and more precise your quote will be.

4. What are the advantages of using your laser cutting service versus doing it myself or buying my own machine?

Answer: Our laser cutting service offers:

Expertise: Our skilled operators ensure optimal settings and precision, minimizing material waste.

High-End Equipment: Access to large-format, meticulously maintained industrial machines without the investment.

Time Savings: We handle the cutting, allowing you to focus on design, marketing, or your core business.

Scalability: Ideal for small to medium production runs, providing consistent quality.

Reduced Risk: No machine maintenance, breakdowns, or costly errors on your part. Our DIY service is perfect for hands-on learning, prototyping, or if you have specific timing needs and want direct control without the full cost of ownership. Buying your own machine is best for very high-volume, continuous production with unique or proprietary needs.

5. What file formats do you accept for custom laser cutting? How should I prepare my files?

Answer: We primarily work with vector-based files for cutting and scoring, such as AI, PDF, or DXF. For engraving, we can use vector files or high-resolution raster images (2.5 d only) (.JPG, .PNG, .TIFF).

File Preparation Tips:

Ensure all lines intended for cutting are vector paths with a hairline stroke (e.g., 0.001").

Set colors for different operations (e.g., red for cuts, blue for scores, black for engraving fills).

Convert all text to outlines/curves.

Ensure your design is scaled 1:1 to the actual size.

Remove any duplicate lines or overlapping paths.

Please indicate the material size you will be providing or requesting. We're happy to provide detailed file setup guides or assist with minor file adjustments if needed.

6. Do you offer rush services or fast turnarounds for custom projects?

Answer: Yes, we understand the fast-paced nature of projects in Los Angeles. We offer expedited services and can often accommodate rush orders depending on our current production schedule and the complexity of your project. Please let us know your deadline when requesting a quote, and we'll do our best to meet your needs. Our standard turnaround times are typically very competitive.

7. Tell me more about your DIY laser cutter rental service. How does it work?

Answer: Our DIY service allows you to rent time on our professional CO2 laser cutters. It's ideal for prototyping, small projects, or hands-on learning. You typically book time slots, bring your own prepared design files, and either your own laser-safe materials or purchase some from us. We provide basic training and supervision to ensure safe and effective use. It's a great way to access high-end equipment without the full commitment of ownership. Contact us for scheduling and introductory course information.

8. What types of laser cutter repairs do you perform?

Answer: We are experts in diagnosing and repairing a wide range of CO2 laser cutters and engravers, regardless of brand. Our services include:

Diagnostics: Remote and on-site troubleshooting to identify the root cause.

Component Replacement: Laser tubes, power supplies, mirrors, lenses, control boards, stepper motors, and more.

Alignment: Precision optical alignment for optimal laser beam path.

Maintenance: Preventive maintenance, cleaning, and calibration to extend machine lifespan.

Softwar Issues: Troubleshooting software errors and ensuring proper machine communication. We aim to minimize your downtime and get your machine back to peak performance.

9. Can I bring my own materials for both custom service and DIY rentals?

Answer: Yes, you are generally welcome to provide your own materials for both our custom laser cutting service and DIY rentals. For custom projects, we may ask for a small sample beforehand for testing, especially if it's a material we haven't worked with extensively. For DIY, please ensure your materials are laser-safe (non-PVC, etc.). We also stock a selection of common laser-friendly materials for purchase if you prefer.

10. Where are you located in Los Angeles, and what are your operating hours?

Answer: We are conveniently located in Los Angeles and operate 11-6 m-f.

American Laser Cutter: Precision, Innovation, and Your Partner in Success

American Laser Cutter is a leading provider of laser cutting services in Los Angeles, California. With a commitment to excellence and innovation, we offer a wide range of laser cutting solutions to meet the diverse needs of our clients.

Our Services:

Custom Laser Cutting: Our team of skilled technicians can create custom laser-cut pieces to your exact specifications. Whether you need intricate signage, personalized products, or architectural models, we have the expertise to bring your vision to life.

Material Cutting: We offer laser cutting services for a variety of materials, including:

Wood

Acrylic

Fabric

Leather

Paper

Cardboard

And more!

Prototyping: Need to quickly and efficiently create prototypes for your new product? Our laser cutting services can help you turn your ideas into tangible objects.

Production: For larger-scale production runs, we can handle the entire process from design to manufacturing.

Training: If you're new to laser cutting, our training programs can teach you everything you need to know to get started.

American Laser Cutter: Setting the Standard for Precision and Innovation

American Laser Cutter stands out from other laser cutting companies due to several key factors:

1. Comprehensive Services:

Diverse Material Capabilities: We can cut a wide range of materials, including wood, acrylic, fabric, leather, paper, cardboard, and more. This versatility allows us to cater to a broad spectrum of client needs.

Custom Designs: Our team of skilled technicians can create custom laser-cut pieces to your exact specifications, ensuring that your vision is brought to life.

Prototyping and Production: Whether you need a single prototype or large-scale production, we have the expertise and capacity to handle your project.

2. State-of-the-Art Equipment:

Advanced Technology: We invest in the latest laser cutting technology to ensure the highest quality results and efficiency.

Precision and Accuracy: Our machines are capable of delivering exceptional precision and detail, even for the most intricate designs.

3. Experienced Team:

Skilled Technicians: Our team consists of experienced professionals who are passionate about laser cutting and dedicated to providing exceptional customer service.

Expertise and Knowledge: Our technicians have a deep understanding of laser cutting technology and can offer expert guidance and support throughout your project.

4. Commitment to Quality:

Strict Quality Control: We have rigorous quality control processes in place to ensure that every project meets our high standards.

Customer Satisfaction: We are committed to providing exceptional customer service and ensuring that our clients are completely satisfied with the results.

5. Competitive Pricing:

Affordable Solutions: We offer competitive pricing on all of our services, making laser cutting accessible to a wide range of businesses and individuals.

6. Local Presence:

Los Angeles-Based: As a Los Angeles-based company, we are able to provide convenient and efficient services to our local clients.

7. Training Programs:

Educational Opportunities: We offer training programs to help individuals and businesses learn more about laser cutting technology and its applications.

In summary, American Laser Cutter differentiates itself through its comprehensive services, state-of-the-art equipment, experienced team, commitment to quality, competitive pricing, local presence, and training programs.

Our Commitment to Quality:

At American Laser Cutter, we are dedicated to providing the highest quality laser cutting services. We use the latest technology and the finest materials to ensure that your projects meet your specifications.

Unleash Your Creativity with Our Massive 4' x 5' Laser Cutter!

Experience the Power of Precision

At American Laser Cutter, we're proud to offer one of the largest laser cutters in the Los Angeles area: our massive 4' x 5' machine. This cutting-edge technology opens up a world of possibilities for your projects, allowing you to create larger, more intricate designs with ease.

Why Choose Our 4' x 5' Laser Cutter?

Bigger is Better: With a spacious 4' x 5' cutting bed, you can tackle larger projects that were previously out of reach. From oversized signage to expansive architectural models, our machine can handle it all.

Unmatched Precision: Our laser cutter delivers exceptional accuracy and detail, ensuring your creations are flawless and professional-looking.

Versatility: Our machine can cut a wide range of materials, including wood, acrylic, metal, fabric, and more. This versatility allows you to bring your most creative ideas to life.

Efficiency and Speed: Our 4' x 5' laser cutter is designed for efficiency, allowing you to complete projects faster than ever before. This is especially beneficial for businesses that need to meet tight deadlines.

Applications for Our 4' x 5' Laser Cutter:

Signage and Displays: Create large-format signage, exhibition displays, and trade show booths that will make a lasting impression.

Architectural Models: Build detailed and accurate architectural models to visualize your designs and communicate your ideas to clients.

Furniture and Home Decor: Create unique and personalized furniture pieces, home decor accents, and custom gifts.

Industrial Components: Produce large-scale components for various industries, such as aerospace, automotive, and manufacturing.

Ready to Experience the Power of Our 4' x 5' Laser Cutter?

Contact us today to schedule a consultation and learn more about how our services can benefit your projects. We're excited to help you bring your vision to life!

American Laser Cutter — Facts & Policies

Welcome! This page explains how our services work, what we accept, and what to expect when you order. We keep things simple: clear file requirements, practical material rules, and straightforward pricing factors. If you’re new to laser cutting, skim the File Prep Checklist and Materials Guide below. If you’re ready to move forward, use our Project Quotes page to send your vector file (AI, DXF, or PDF). Visits are by appointment only at our Downtown Los Angeles location. Repairs are on-site or remote; we do not accept repair drop-offs at the shop. If you don’t see your answer here, send us a message and we’ll help.

What We Do

- Precision laser cutting & engraving for signs, displays, packaging parts, models, gifts, and prototypes.

- Project quoting: upload your design; we cut/engrave and deliver finished parts.

- Laser cutter rental: available by the hour after training (see the Laser Cutter Rental page).

- CO₂ laser repair & maintenance: on-site or remote only (no drop-offs).

File Requirements (Vector Only)

- Accepted formats: AI, DXF, PDF (vector). We do not accept raster-only files (JPEG, PNG, TIFF, etc.).

- Scale & units: Set your file to the final size in inches or millimeters (note which one in your quote form).

- Clean paths: Join open curves; remove duplicates and overlaps; no tiny stray points.

- Colors / layers: Separate cut, score, and engrave on distinct layers or colors. Add a legend if helpful.

- Text to outlines: Convert all fonts to outlines/curves.

- Artboard & margins: Keep all geometry within the artboard; leave edge clearance so parts don’t fall outside your sheet.

- Kerf awareness: Very thin bridges and tiny holes can be affected by kerf. If a dimension is critical, note it in your submission.

Materials Guide

- Commonly used: Acrylic, plywood/hardwoods, cardboard/paperboard, certain fabrics and leathers marked laser-safe.

- Customer-supplied material: Welcome—must be laser-safe and clean/flat. We may ask for a scrap piece for a test.

- Masking: Paper mask helps reduce smoke marks on woods and keeps acrylic surfaces clean; use if finish matters.

- Edge finish expectations:

- Acrylic: edges are typically glossy from cutting; tiny witness marks may occur at start/stop points.

- Wood: some edge darkening/char is normal; sanding/sealant can reduce contrast.

- Not permitted / safety: No PVC or vinyl (releases hydrochloric acid), no unknown plastics, no materials with chlorine content, no painted/treated woods with unknown coatings. If unsure, ask first.

How Pricing Works

- What drives cost: design complexity, size, material, quantity, and whether engraving is included.

- File readiness: clean vector files keep pricing predictable. We’ll flag issues before work begins.

- Quantity effects: larger quantities often reduce per-unit cost (setup time spreads out).

- Material sourcing: supply your own laser-safe material or ask about what we have on hand.

- Finishing: extra steps (masking, light sanding, adhesive backing, etc.) may add cost; tell us if you need them.

Turnaround & Scheduling

- Typical timelines: Many projects complete within a few business days depending on complexity and queue.

- Rush options: Often available; tell us your deadline and we’ll advise what’s realistic.

- Appointments only: Please schedule before visiting our Downtown LA shop.

Repairs & Maintenance

- Service scope: diagnostics, alignment, optics cleaning, motion/belt issues, cooling or exhaust faults, parts replacement.

- Where we service: on-site at your location in Los Angeles (and nearby) or remote support when feasible.

- Policy: no repair drop-offs at the shop.

Shipping, Pickup & Handling

- Pickup: by appointment only. Pack loose parts for transport to avoid damage.

- Shipping: if you need shipment, note it on your quote; we’ll outline packing options and cost.

- Quality checks: we inspect parts before release; let us know within a reasonable window if something seems off.

Design Tips for Better Results

- Avoid hairline bridges on delicate parts; add tabs where pieces get narrow.

- Nest parts efficiently to reduce waste (and cost).

- Engrave with intent: vector hatch/fill engraves cleanly; keep large solid fills minimal to save time.

- Label layers clearly (e.g., “CUT 0.125in Acrylic”, “SCORE”, “ENGRAVE LOGO”).

- Provide notes for critical dims or fit areas (press-fit vs. slip-fit, etc.).

Frequently Asked Questions

- What files do you accept?

AI, DXF, or PDF vector files. We don’t accept raster-only files like JPEG or PNG. - Can you use my material?

Yes—if it’s laser-safe, clean, and flat. We may request a scrap for a test cut/engrave. - Do you engrave as well as cut?

Yes. We can vector-engrave logos, text, and patterns. Keep engrave areas reasonable to control time/cost. - How do I prevent burn marks on wood?

Use masking, avoid excessive power, choose clean stock, and expect light edge darkening as normal. - Will acrylic edges be glossy?

CO₂ laser cutting usually yields smooth, glossy acrylic edges. Small start/stop marks can occur. - Do thin details break easily?

Very thin bridges can be fragile. Add tabs or increase thickness in high-stress areas. - What if my part has critical dimensions?

Note them in your submission. We’ll advise best practices for kerf and fit (press/slip). - Can you fix my file?

We’ll flag issues. If major edits are needed, we’ll discuss options before proceeding. - How do you price a project?

By design complexity, size, material, quantity, and engraving time, plus any finishing you request. - Do larger orders cost less per unit?

Usually yes—setup time is spread across more pieces. - How long does a project take?

Timing depends on complexity and queue. Tell us your deadline and we’ll advise what’s realistic. - Can you rush an order?

Often, yes. Let us know your timeframe when you submit for a quote. - Can I drop off a laser cutter for repair?

No. Repairs are on-site at your location or remote only. - Do you accept walk-ins?

No. All visits are by appointment only. - What’s the fastest way to get a quote?

Submit an AI, DXF, or PDF vector file with material, thickness, quantity, and any notes about critical dimensions. - Do you keep my designs private?

Yes. We treat your files as confidential and only use them to produce your order. - Can you apply adhesive backing?

On request, for certain materials. Mention it in your quote if you need peel-and-stick parts. - Do you do finishing or painting?

Light finishing steps may be available; painting/coatings are not standard. Ask if you have a specific need. - What materials are not allowed?

No PVC/vinyl, no unknown plastics, and no materials with chlorine content. Ask if unsure. - What happens if my file isn’t vector?

Please convert to vector (AI/DXF/PDF). If you’re unsure how, we can point you to resources.