Get a Quote

(cost comparison below)

Quote & Visit Policy

Quotes: Accepted via Form or Email only. No phone quotes.

Visits: Strictly by appointment.

File Preparation Guidelines

Formats: AI, DXF, or PDF (Vector).

PDF is often the safest export.

Raster Images: JPEG/PNG are for

photo engraving only.

Scale: 1:1 (Real-world dimensions).

Line Weight: Hairline or .001”.

Organization: Map operations by color (Cut vs. Score vs. Engrave) on a single layer. Remove all hidden objects.

Export Settings (DXF/CAD)

Version: AutoCAD 2023 or earlier.

Units: Millimeters (Switch to mm before exporting).

Text: Convert to Curves/Outlines.

Curves: Export as Splines.

Fills: Unfilled (Wireframe only).

Bitmaps: PNG.

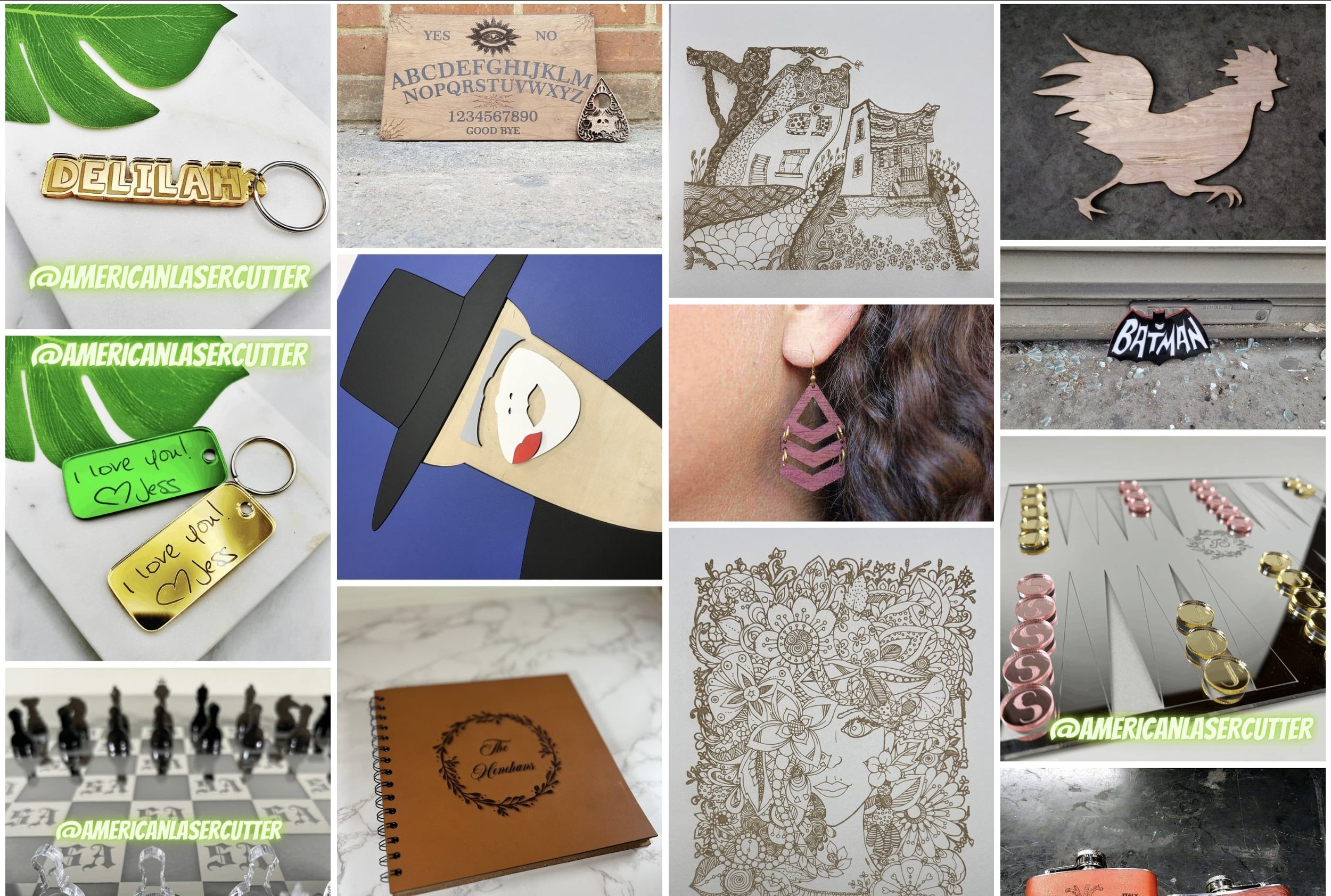

Why Choose American Laser Cutter

• Human-assisted quoting that catches issues early

• Practical nesting guidance to reduce waste

• Prototype to short-run production with one partner

• Use our stock or bring your own laser-safe materials

Start Your Quote

Email your AI/DXF/PDF and details to: americanlaserco@gmail.com

If you prefer a form, add an upload field and the questions above—then route submissions to the same email.

What we stock

Clear, black, white acrylic in 1/8” and 1/4”

Plywood in 1/8” and 1/4”

Cost comparison

for a more detailed breakdown, please visit the cost comparison page

American Laser Cutter: $56.70 (Cutting $46.20 + Material $10.50)

Local Competition #1: $168.00 (Cutting + Material)

Local Competition #2: $125.00 (Cutting + Material)

Ponoko: $74.61 (Cut $68.96 + File check $5.01 + Finishing $0.64)

SendCutSend: $126.40 (no itemized breakdown)

Rent our laser: $26+ (see bottom for breakdown)

Laser Cutting Quotes and Production in Los Angeles — From First Prototype to Full-Scale Manufacturing

Get a fast, accurate quote for laser-cut parts and scale confidently from a single prototype to large, repeatable production. This page explains exactly how to work with American Laser Cutter for precision 2D parts, model components, signage elements, jigs and templates, brand pieces, and simple packaging elements that support a product launch. Quotes are handled through a form. Visits are by appointment only.

What we make

Laser cutting is ideal for parts that demand clean edges, tight repeatability, and efficient turnaround without the tooling costs of other processes. Typical outputs include:

Product components in non-metallic sheet materials

Acrylic panels, covers, windows, risers, and display elements

Spacers, shims, and non-metallic brackets

Stencils, templates, and assembly jigs

Sign and brand elements for retail and events

Study models for education and client reviews

Light packaging aids such as sleeves or cards when helpful for a launch

Full production, not just short runs

Whether you need one unit for a fit check or thousands for a release, the workflow is designed to scale. After your first approved run, we retain process details such as cut parameters, masking preferences, score depth, labeling conventions, and packing notes. That record keeps later orders consistent. For steady demand, we can plan rolling releases, group by SKU, and kit parts to match your assembly order. If your schedule is cyclical, we can align batches to your internal milestones so replenishment is predictable.

Materials we work with

We process clearly identified, laser-safe sheet materials including cast acrylic (clear, translucent, and opaque colors), hardwoods, plywoods, paperboard and cardstock, chipboard, and oil board. If you plan to provide your own laser-safe material, note sheet size, thickness, and quantity in the quote request so yield can be estimated and handling can be planned.

Materials we do not process

For safety and edge quality, we do not process metals or unknown plastics. We also decline MDF, faux leather, PVC, ABS, PETG, polycarbonate, and Delrin.

How quoting works

Quotes are straightforward and based on the specifics of your file and the outcomes you want.

Use the quote form to upload your vector file and share key details such as material, thickness, quantity, largest part size, operations needed, and fulfillment preference.

Your file is reviewed for manufacturability and material safety. If something would affect cost, fit, or finish, you will receive concise notes with options.

You receive a written estimate with clear line items. Nothing proceeds until you approve.

What to include for the fastest, most accurate estimate

Providing a few specifics up front eliminates guesswork:

Material and thickness, or a request for a recommendation

Quantity of each part or a simple total part count

Largest single part size and any constraints on overall panel size

Operations required: cut only, cut plus light vector score, or cut plus vector engrave

Edge preference: standard clean cut; request a line item for flame-polished edges if needed

Organization preferences such as bag by SKU, stack by assembly, or flat-packed sets

Fulfillment preference: local pickup by appointment or shipping within the U.S.

Any critical dimensions, slot fits, or assembly notes we should preserve

Pricing factors and ways to control cost

Laser-cut pricing is driven by total cut length and complexity, material type and thickness, part count, and setup. Because these inputs are predictable, careful preparation often lowers cost without changing the look or function of your parts.

Remove doubled or overlapping lines that would otherwise cut twice

Share edges between adjacent parts where appropriate to reduce cut length

Convert nonfunctional cuts to light scores for folds or registration marks

Orient parts for efficient nesting while protecting visible edges

Label parts in the artwork so packing and kitting can be efficient

When a choice affects price meaningfully, the estimate will call it out so you can decide.

File preparation guidelines

Clean vector files make quoting faster and production more reliable.

Accepted formats: AI, DXF, or PDF (vector only)

Scale: set units and supply 1:1 geometry

Separation: keep cuts, scores, and vector engraves on distinct layers or colors

Text: convert to outlines

Geometry hygiene: remove hidden objects and duplicates, and join open paths that should cut continuously

Multi-SKU jobs: label parts in the artboard or include a simple part list

If the file needs a small adjustment for consistency or clarity, you will receive a short note describing the change that will preserve intent and improve results.

Prototype to production continuity

Consistency matters as you scale. Once a first article is approved, the parameters that produced it become the reference for future runs. That includes lens settings for edge clarity, pass counts for delicate features, masking decisions for surfaces that must remain pristine, and packing methods that keep sets organized. If a design revision changes any behavior, the estimate will highlight the difference so you know what to expect.

Quality and tolerances

The goal is repeatable fit and finish. In practice, that means controlled kerf, edges that present well on visible faces, and parts that sit flat right out of the box. Tolerances are kept realistic for the chosen material and thickness, and heat-affected behavior is considered for features like small slots, fine internal radii, living hinges, and narrow bridges. If a specific geometry risks charring or weakness, it will be flagged before production so you can adjust with confidence.

Production workflows for every size

Every project is different. Some teams need quick one-offs during a sprint, others need reliable short runs for pilots, and many require full-volume releases with recurring replenishment. The production workflow supports:

Single pieces and engineering samples for verification and demos

Short runs for launches, pilots, limited editions, and events

Large releases for established products, with repeatable setup and packing

Ongoing replenishment coordinated to your internal schedule or rolling purchase orders

Kitting and labeling that mirror the way your team assembles or ships finished goods

Fulfillment and handling

Local pickup is available by appointment in Downtown Los Angeles. For projects outside the area, shipping is available throughout the United States. Packing is designed to protect edges, preserve flatness, and keep parts grouped in a way that aligns with your build sequence. If you need a specific labeling convention or kitting order, include that instruction in your quote request and it will be reflected in the estimate.

Why teams choose this approach

A human reviews your artwork before pricing, which reduces errors and exposes cost-saving opportunities early. Communication is concise and focused on outcomes. Estimates are transparent about material, operations, and options. Production settings are preserved so reorders match the standard you approved. The process is built to scale, which removes friction as your product moves from prototype to steady production.

Frequently asked questions

Do you accept raster images such as JPEG or PNG

No. Vector artwork is required. Accepted formats are AI, DXF, and PDF.

Can I provide my own material

Yes, provided it is clearly identified and laser-safe. Include sheet size, thickness, and quantity so yield can be estimated and handling can be scheduled.

Can you handle very large orders

Yes. The workflow supports everything from single pieces to large, repeatable releases. Once a first article is approved, the same look and fit are maintained for full-volume production.

How do you keep costs reasonable without changing the design

By removing overlapping lines, sharing edges where appropriate, converting certain cuts to scores, and nesting parts efficiently. When these choices are relevant, the estimate will show them as options so you stay in control.

How do I get started

Use the quote form to upload your AI, DXF, or PDF file along with material, thickness, quantity, largest part size, operations needed, and fulfillment preference. You will receive a clear estimate before production. Quotes are handled by form only. Local visits are by appointment.

Want finished parts without running a machine? Send us your design and we’ll handle cutting and engraving for you. Upload a proper vector file (AI, DXF, or PDF), tell us your material and quantity, and we’ll reply with a clear price. We check files for common issues and let you know if anything needs fixing before we start. This is the easiest way to get professional results for one item or a short run—perfect for signage, packaging parts, gifts, and prototypes. You can supply laser-safe material or ask us about stock options. Quotes are usually quick, and we’ll answer your questions before you commit.

FAQs

- What files do you accept?

AI, DXF, or PDF vector files. - Can you provide material?

Yes. You can also bring your own laser-safe material. - How fast do quotes come back?

Usually within one business day. - Do you check my file?

Yes. We look for issues like open paths or overlaps and let you know before we cut. - What affects price?

Design complexity, size, quantity, material, and whether engraving is needed.