Laser 101: f.a.q and tips about Laser cutting

New to laser cutting? Start here. We explain the basics—how CO₂ lasers cut and engrave, which materials are safe, and how to set up your file. You’ll learn the difference between cutting and engraving, why vector files matter, and simple ways to avoid burn marks or rough edges. We also cover safety, ventilation, and tips for better results. Whether you plan to rent a laser or have us do the work, this quick guide will help you make confident choices and get cleaner parts.

FAQs

- Cutting vs. engraving—what’s the difference?

Cutting goes through the material; engraving marks the surface. - Which materials are safe to cut?

Common options include acrylic, wood, cardboard, some fabrics, and other laser-safe materials. Avoid PVC and unknown plastics. - Why won’t JPEG or PNG work for cutting?

They don’t contain paths. Laser cutters need vector files like AI, DXF, or PDF. - What software should I use?

Illustrator or LightBurn are common choices. Export clean vectors at the correct scale. - Any quick tips for cleaner results?

Use the right material, nest parts to save stock, keep optics clean, and choose sensible power/speed settings.

Laser Rental for Makers

Build Hollywood-Level Props on a DIY Budget: Laser Rental for Makers

If you are building armor for a convention, a weapon prop for a short film, or a set model for a pitch, you know the pain of hand-cutting. X-Acto knives slip, Dremels are messy, and getting perfectly symmetrical geometric shapes by hand is nearly impossible.

American Laser Cutter offers a solution that used to be reserved for big-budget FX shops: Hourly Industrial Laser Rental. Located in Downtown Los Angeles, our workshop gives independent prop masters and cosplayers access to the heavy machinery needed to create screen-accurate details without the massive price tag.

Why Hand-Cut When You Can "Beam" It?

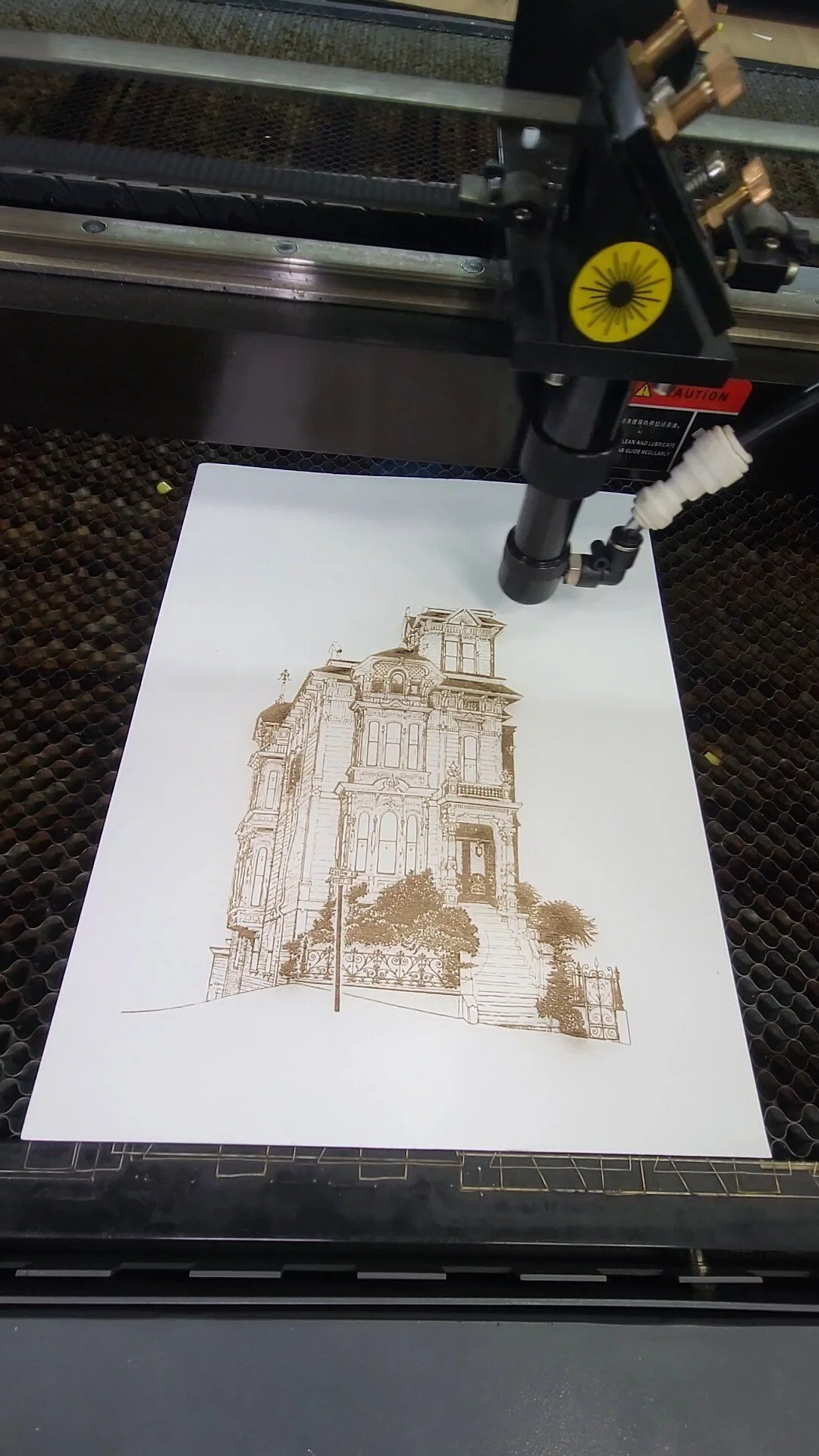

Complex patterns that take hours to score and cut by hand can be finished in minutes on our machines.

Perfect Symmetry: Need two identical bracers or a 12-piece geometric helmet? A laser cuts them identically every time.

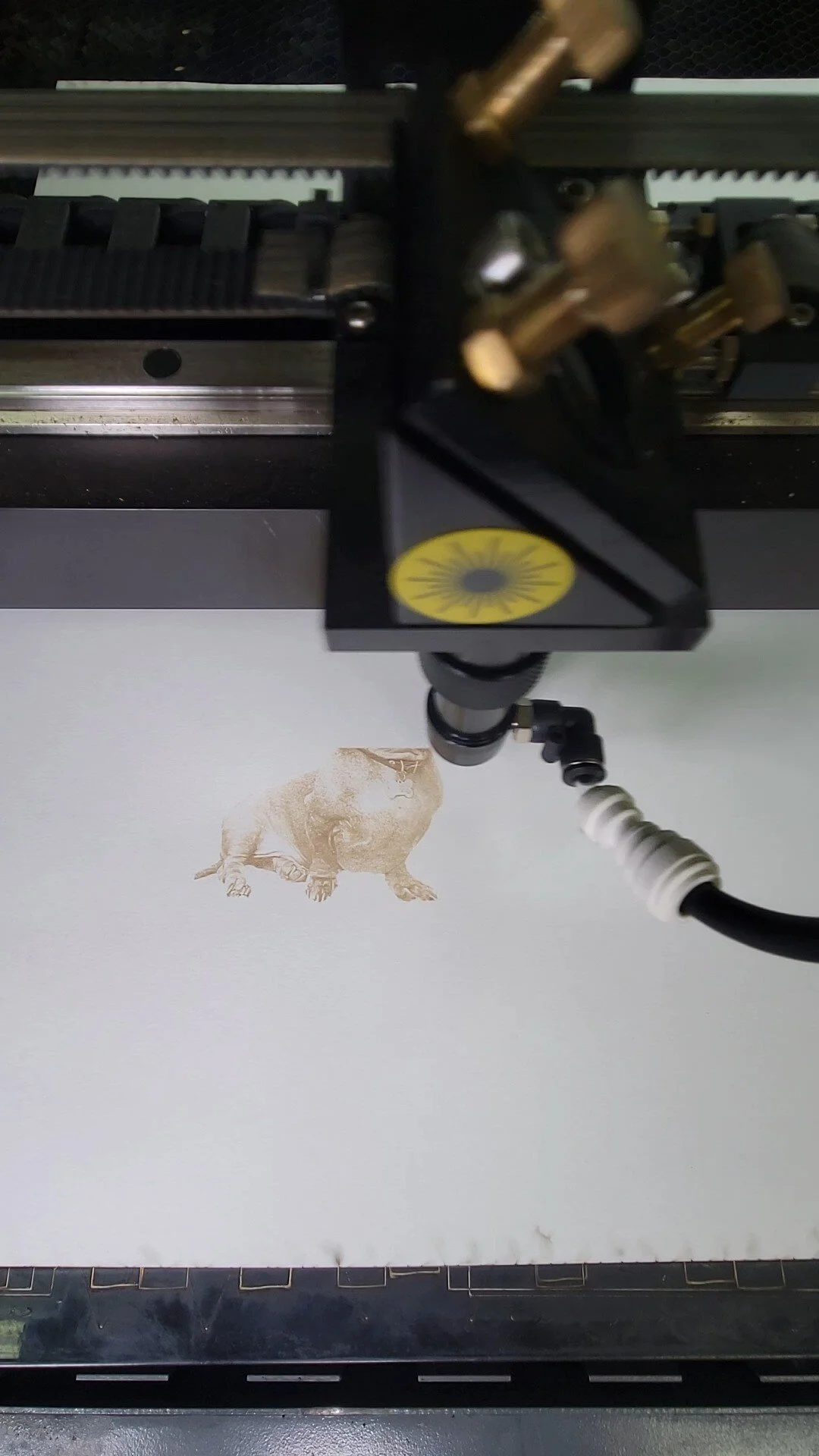

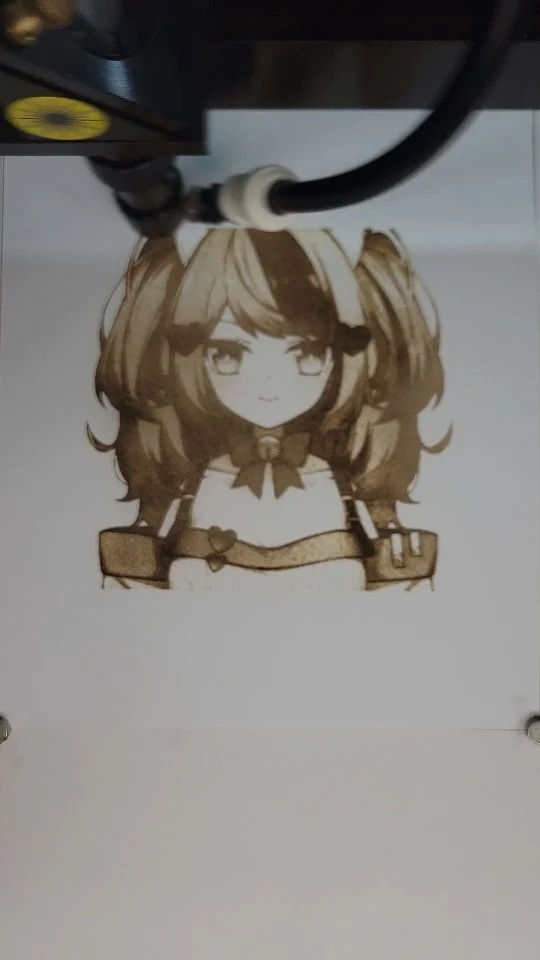

Micro-Detailing: Engrave fine elvish script, cybernetic circuit lines, or weathered textures directly into your material with a precision no human hand can match.

Rapid Sizing: Did you 3D print a helmet that’s slightly too small? Laser cut a quick sizing gauge out of cardboard in seconds to test the fit before committing to expensive materials.

Materials for the Modern Armorer

Our 100W+ CO₂ lasers are significantly more powerful than the "hobby" lasers you might see in a home garage, allowing you to work with denser, more durable materials for your builds.

EVA Foam (Safety Check): While we strictly prohibit PVC (Sintra) and Vinyl due to toxic fumes, many laser-safe foams can be cut for base armor layers. Always check with us first regarding your specific foam brand.

MDF & Plywood: The standard for structural props. Cut the skeleton of a giant buster sword or the frame of a sci-fi rifle out of sturdy 1/4" MDF, then clad it in foam or 3D prints.

Acrylic (Plexiglass): Essential for "energy" weapons, light-up visors, and futuristic display screens. We can cut clear, colored, or mirrored acrylic with crystal-clear polished edges.

Leather: Create high-end fantasy armor, belts, and holsters. The laser seals the edge as it cuts, preventing fraying, and can burn intricate guild patterns directly into the surface.

Go Big or Go Home

Most home lasers have a tiny 12" x 20" bed. That’s useless for a shield or a breastplate.

Our machines feature 48" x 60" cutting beds, allowing you to:

Cut full-scale staff or spear components in one piece.

Layout an entire suit of armor’s flat patterns on a single sheet to minimize waste.

Produce large-scale signage or set decoration elements for your booth or background.

How It Works for Makers

You don’t need to be an engineer to use our shop.

Design: Export your 2D patterns (from Inkscape, Illustrator, or even unfurled 3D meshes) as .DXF, .AI, or .PDF files.

Book: Reserve a machine by the hour. (Monday–Friday, 10 am–6 pm).

Cut: Bring your material (or buy wood/acrylic from us) and run the job yourself.

Note: We have a "No PVC/Vinyl" rule. If you aren't sure if your material is safe, ask us!

Stop Outsourcing Your creativity

When you order online, you wait two weeks just to find out a part doesn't fit. When you rent a machine at American Laser Cutter, you leave with your finished parts the same day.

Studio Address: 1319 South Los Angeles St, Los Angeles, CA 90015

Reserve Your Time: Email americanlaserco@gmail.com or call 213-866-4738.

New to Lasers? Ask about our Intro to LightBurn class to learn how to prep your cosplay files for cutting.

Cut Your Own Collection diy laser cutting

Cut Your Own Collection: The Secret Weapon for LA Fashion & Jewelry Designers

If you are a designer in the Los Angeles Fashion District, you know the struggle: you have a vision for a custom acrylic earring line or a complex leather bag pattern, but the production hurdles are massive. Factories demand 500-unit minimums, and local job shops charge a fortune for "prototyping fees."

American Laser Cutter flips the script. Located right here in the Fashion District (near 12th & Los Angeles St), our Hourly Laser Rental Program gives you direct access to the machinery you need to build your brand on your own terms.

From Sketch to Runway in One Afternoon

In the fashion world, trends move fast. Waiting two weeks for a sample usually means missing the boat. By renting our industrial CO₂ lasers, you take control of your timeline.

Instant Sampling: Bring your vector file and material. Cut a leather insole or an acrylic pendant, test the drape and fit, adjust the design on your laptop, and cut the final version—all in a single one-hour booking.

No Minimum Orders: Whether you need one avant-garde showpiece for a runway look or 50 pairs of earrings for a pop-up market, you decide the quantity.

Protect Your Designs: Stop emailing your unreleased collection patterns to third-party vendors. Keep your IP safe by handling the fabrication yourself.

Materials We Handle (That Your Studio Cutter Can’t)

Forget struggling with X-Acto knives or weak diode lasers that scorch your edges. Our 100W+ Industrial Systems are calibrated for the materials fashion pros use daily:

Acrylics & Lucite: Create crystal-clear jewelry, handbag hardware, and futuristic structural elements with flame-polished edges straight off the machine.

Leather & Textiles: Cut intricate lace patterns into vegetable-tanned leather or synthetic fabrics without fraying. Note: We strictly prohibit PVC/Vinyl due to toxicity.

Natural Woods: Perfect for branding tags, buttons, and rigid handbag structures.

Designed for the "Small Batch" Hustle

You don’t need a factory to produce a collection. You just need the right tools.

Massive Cutting Area: Our 48" x 60" beds are large enough to lay out half-hides of leather or full sheets of acrylic, maximizing your yield and minimizing scrap waste.

Precision Engraving: Etch your logo directly onto your products with microscopic detail, adding a premium finish that justifies a higher price point.

Cost Control: Renting by the hour means you pay for time, not per-piece. Efficient designers can cut hundreds of dollars worth of inventory in a single session for a flat hourly rate.

No Experience? No Problem.

You know Illustrator; we know lasers. If you’ve never operated a machine before, we offer a "Laser 101" orientation to get you up to speed safely. We also provide LightBurn software training so you can learn how to nest your jewelry parts perfectly to save money on expensive acrylic sheets.

Your Studio Extension in DTLA

Stop outsourcing your creativity. Book a machine, walk in with your materials, and walk out with finished product.

Location: 1319 South Los Angeles St, Los Angeles, CA 90015 (Heart of the Fashion District)

Access: Mon-Fri, 10am–6pm (By Appointment Only)

Book Your Slot: Email americanlaserco@gmail.com or call 213-866-4738 to reserve your machine time.

Unlock Professional Laser Cutting in Downtown LA: Rent, Create, and Prototype

Unlock Professional Laser Cutting in Downtown LA: Rent, Create, and Prototype

For Los Angeles-based designers, architects, and entrepreneurs, the barrier to high-quality fabrication often isn't creativity—it's access. American Laser Cutter provides a streamlined solution: an on-demand laser workshop right in the heart of the Fashion District. By offering hourly machine rentals, this facility empowers you to take full control of your production process, bridging the gap between expensive outsourcing and unaffordable equipment ownership.

Why Rent a Laser Cutter?

In the fast-paced world of product design and architectural modeling, waiting days for a quote and weeks for shipping isn't an option. The DIY rental model offers three critical advantages:

Immediate Iteration: Prototype a design, spot a flaw, adjust your vector file, and re-cut—all in a single afternoon.

Cost Efficiency: avoid minimum order fees and setup charges. You pay only for the time you use.

Hands-On Control: Perfect your settings for engraving depth and cut quality personally, ensuring the final piece matches your vision exactly.

Industrial-Grade Specs for Serious Makers

Forget the limitations of small desktop diode lasers. Renters at American Laser Cutter gain access to powerful CO₂ laser systems designed for commercial throughput.

High Power: With machines ranging from 100W to 180W, you can slice through thicker materials with speed and a polished edge finish.

Large Format Beds: The expansive 48” x 60” work area accommodates full architectural sheets, furniture components, and large-scale signage that smaller hobby machines simply can’t handle.

Software Compatibility: The workshop utilizes LightBurn, the industry-standard software known for its robust editing and control features, accepting major vector formats like AI, DXF, and PDF.

Who Benefits from On-Demand Access?

This open-access workshop serves a diverse ecosystem of creators across Southern California:

Architecture & Design Students: When university labs at USC or SCI-Arc are backed up, students can rely on this facility to finalize intricate site models and topography layers before deadline.

Hardware Startups: Rapidly prototype enclosures and faceplates for investor pitches without committing to expensive injection molding tools.

Fashion & Prop Designers: Create custom acrylic jewelry, leather patterns, or set pieces for film and retail displays.

How the Rental Process Works

Getting started is designed to be frictionless for competent users.

Book Your Slot: Sessions are available by appointment, ensuring you have a dedicated machine upon arrival.

Safety First: New users complete a mandatory orientation to learn shop protocols and emergency procedures.

Material Sourcing: You are free to bring your own materials—including wood, plywood, acrylic, cardboard, and leather—or purchase stock on-site. Note: For safety and equipment preservation, PVC, vinyl, and metals are strictly prohibited.

Execute: Load your files, set your focal point, and run your job with staff available nearby for troubleshooting.

Level Up Your Skills: LightBurn Training

If you are new to digital fabrication, the shop offers a dedicated LightBurn Training Course. This one-on-one session (available in-person or remotely) covers the essentials of vector preparation, power/speed optimization, and file management, ensuring you get the most value out of your rental hours.

Visit the Workshop

Located centrally for easy access from all major LA neighborhoods, American Laser Cutter is your local partner in precision fabrication.

Hours: Mon-Fri, 10:00 AM – 6:00 PM (Appointment Only)

Contact: americanlaserco@gmail.com | 213-866-4738

✨ Shine Bright: Laser-Cut Glitter Acrylic Eyeglasses and Headbands

✨ Shine Bright: Laser-Cut Glitter Acrylic Eyeglasses and Headbands

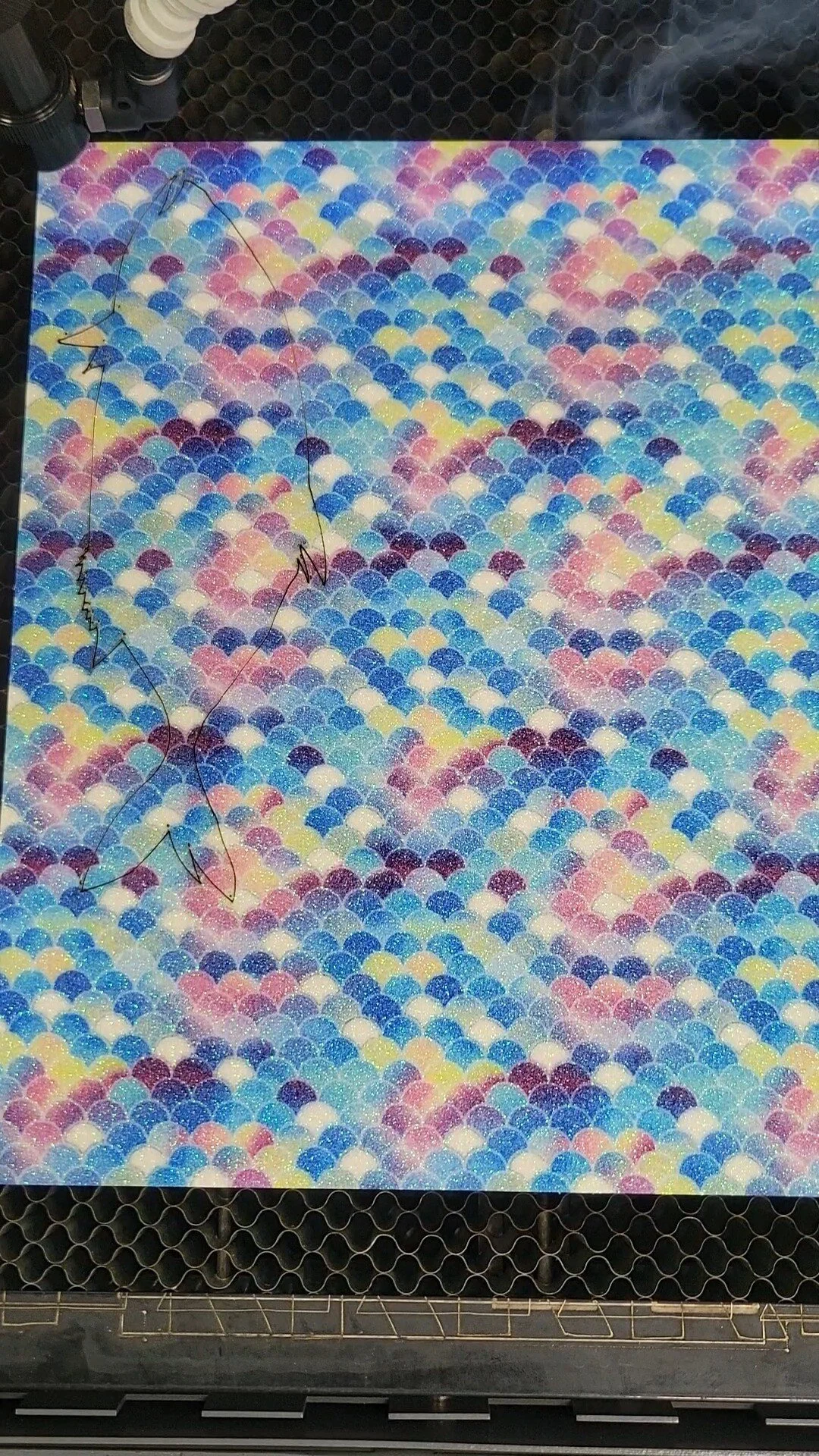

New Year's Eve is all about sparkle, and nothing says celebration like custom party accessories. Laser cutting is the perfect way to produce custom eyeglasses, headbands, and bowties quickly and precisely using glitter and mirror acrylics, making for memorable photo opportunities and party favors.

This article details the materials and techniques for creating dazzling NYE wearables.

I. Choosing the Right Materials

The key to flashy NYE accessories is selecting high-impact, lightweight acrylics.

Glitter Acrylic: This is the ideal material. It is clear acrylic embedded with glitter flakes. The laser cuts through it cleanly, and the cut edges often appear polished. Purchase 1/8 inch (3mm) thick glitter acrylic in festive colors like gold, silver, or black.

Mirror Acrylic: Provides a high-gloss, reflective surface. Only use extruded mirror acrylic; cast mirror acrylic often breaks down during laser cutting. Always cut mirror acrylic with the mirrored side down to prevent the beam from reflecting back into the laser.

Headband Blanks: Save time by purchasing inexpensive plastic headband blanks. Your laser-cut designs can be quickly and easily glued to these bases.

II. Designing and Cutting Eyeglasses

Creating functional eyeglasses requires careful design to ensure the frames are comfortable and durable.

Design Files: Look for ready-to-cut Laser Cut New Year's Glasses SVG files that feature the year ("2026") or common phrases like "Happy New Year."

Creating Hinge Points: Most simple laser-cut eyeglasses are designed to be cut as one flat piece. To achieve an over-the-ear piece that bends, some designs use flex joints or living hinges cut from thinner material, while others rely on cutting the main frame and gluing on separate, straight earpieces.

Laser Settings: Since acrylic can melt and flame, use high air assist and slightly higher speed to achieve a clean, polished edge. Slow speeds can cause the acrylic to gum up and create rough edges.

III. Assembly and Finishing

Headbands: Cut your design (e.g., stars, a large "2026," or a mini top hat) from glitter acrylic and use a strong glue, such as E6000 or specific acrylic cement, to attach the design to the plastic headband blank (Source: [suspicious link removed]).

Bowties/Pins: For bowties or pins, cut the shape and glue a small metal pin back to the reverse side. This allows the accessory to be easily clipped to a shirt or jacket.

How to Get Cleaner Edges in Laser Cut Acrylic

How to Get Cleaner Edges in Laser Cut Acrylic

The Secret to a Polished, Professional Finish

Acrylic is one of the most popular materials for CO₂ laser cutting because of its precision, versatility, and ability to produce crystal-clear edges. Yet many users struggle with hazing, frosting, or melted edges that ruin an otherwise perfect cut. Getting smooth, clean results requires the right combination of machine setup, material choice, and environmental control.

1. Choose the Right Type of Acrylic

Not all acrylic reacts the same way to a laser.

Cast acrylic produces clear, flame-polished edges and engraves with crisp contrast.

Extruded acrylic cuts faster but tends to have a cloudy edge and softer engraving definition.

Pro tip: For professional projects, always use cast acrylic—it delivers more consistent optical clarity and better surface results.

2. Optimize Laser Settings

Finding the right power and speed balance is crucial.

Too much power causes melting and bubbling.

Too little power leaves uncut sections or rough edges.

Ideal setup: Medium-to-high speed with just enough power to cut cleanly through the sheet in one pass.

At American Laser Cutter, every job is calibrated to the acrylic thickness and wattage of our lasers (ranging up to 180W). That ensures full penetration without thermal distortion.

3. Maintain Proper Focus and Air Assist

A sharp focal point delivers the smoothest cut. Dirty lenses, mirrors, or improper focus can scatter the beam and cause cloudy edges.

Air assist also makes a major difference—it clears vaporized material from the cutting area and prevents re-fusing along the edges. Clean, dry air at a steady flow gives the best clarity.

4. Keep the Material Cool and Stable

Acrylic expands with heat. Continuous long cuts can cause warping or tapering if the sheet gets too hot. Use elevated supports under the sheet and consistent ventilation across the cutting bed to dissipate heat evenly.

If needed, pausing briefly between passes lets the material cool and prevents internal stress cracks.

5. Avoid Flame Polishing After Laser Cutting

While some people try to “fix” hazy edges with a torch, it can introduce stress and clouding. A properly tuned laser should already leave a flame-polished finish. Post-processing is unnecessary if the beam focus and power are set correctly.

Professional Cutting for Perfect Edges

At American Laser Cutter, we specialize in achieving optical-grade results on acrylic for signage, displays, and precision parts. Using tuned CO₂ lasers up to 4’×5’ in size, we deliver smooth, flame-polished edges straight from the machine—no sanding or polishing required.

Clients can supply their own acrylic or select from our in-house materials, available in multiple colors and thicknesses.

Conclusion

Clear, professional acrylic cuts depend on fine-tuned settings, clean optics, and the right material. When handled correctly, laser-cut acrylic edges should come out polished and perfect on the first pass.

If you need precision acrylic cutting with professional clarity, American Laser Cutter can handle your project—on-site in Los Angeles or remotely anywhere in the U.S.

Email americanlaserco@gmail.com or visit americanlaserco.com to request a quote.

Laser Cutting in Architecture and Interior Design

Here’s the next fresh, copy-ready article in the seriLaser cutting has moved well beyond the factory floor. In 2025, it is a design tool shaping how architects and interior designers create both models and finished environments. The precision, speed, and flexibility of laser technology allow professionals to realize ideas that were once too complex or costly.

Scale Models and Prototypes

Architects often begin with models to visualize projects. Laser cutters make this process faster and more detailed.

Cardboard and Paperboard Models: Quick, affordable, and precise.

Acrylic and Wood Models: Durable materials for client presentations.

Complex Facades: Intricate window grids, latticework, and textures cut cleanly.

Laser-cut models improve communication between designers, clients, and builders.

Decorative Panels and Screens

Interior designers frequently use laser cutting for functional art.

Room Dividers: Custom-cut patterns in wood or acrylic.

Wall Panels: Geometric or organic shapes for texture and style.

Lighting Fixtures: Perforated designs that create striking shadows.

These elements blend utility with aesthetics, turning simple materials into focal points.

Furniture and Fixtures

Furniture makers and designers integrate laser cutting into their workflows.

Wood Components: Chairs, shelves, and tables with precise joints.

Metal Accents: Decorative steel or aluminum inserts.

Custom Hardware: Unique pulls, handles, or brackets.

The repeatability of laser cutting ensures every piece matches perfectly, even in large runs.

Branding in Commercial Interiors

Businesses often want their spaces to reflect their identity. Laser cutting makes branding part of the environment.

Logo Cutouts: Featured in reception desks or wall panels.

Custom Signage: Consistent brand imagery throughout a space.

Unique Fixtures: Tables, counters, or shelving customized with brand motifs.

This integration strengthens brand presence for customers and employees alike.

Sustainability and Materials

Sustainability is a growing factor in architecture and design.

Recycled Materials: Acrylics and woods sourced from reclaimed stock.

Eco-Friendly Composites: Safe alternatives to hazardous plastics.

Efficient Nesting: Laser software reduces material waste.

These practices align with modern design goals of environmental responsibility.

Questions & Answers

Q1: Why do architects use laser cutting for models?

A: It allows them to produce highly detailed, accurate models quickly for review and presentation.

Q2: Can laser cutting be used for interior design features?

A: Yes, it’s popular for wall panels, lighting fixtures, and custom decorative screens.

Q3: How does laser cutting help furniture makers?

A: It creates precise joints, consistent parts, and decorative accents that are repeatable at scale.

Q4: Is laser cutting sustainable in architecture?

A: With eco-friendly materials and efficient software, it supports greener design practices.

Q5: Do commercial spaces benefit from laser cutting?

A: Absolutely. Businesses use it for branding, signage, and custom furniture to enhance their interiors.

Laser Cutting in the Fashion Industry — Style Meets Technology

Fashion thrives on innovation, and in 2025, laser cutting is one of the most powerful tools reshaping the industry. Designers now use lasers to cut fabrics, engrave leather, and create details that would be impossible with scissors or dies. The result is garments and accessories that combine artistry with cutting-edge precision.

Fabric Cutting and Pattern Making

Traditional pattern cutting is time-consuming and prone to human error. Laser cutters streamline this step.

Precision: Patterns cut with millimeter accuracy.

Efficiency: Multiple layers of fabric cut in a single pass.

Complexity: Shapes and designs that are impossible by hand become achievable.

This allows designers to focus on creativity instead of production limitations.

Leather Engraving and Customization

Leather is one of the most popular fashion materials for laser work.

Custom Logos: Brands engrave logos or monograms directly into products.

Texture Creation: Lasers etch detailed patterns, adding depth and uniqueness.

Clean Edges: Cuts are sharp and consistent, unlike blade cutting which may fray.

Laser-engraved leather bags, belts, and shoes are increasingly common in luxury markets.

Jewelry and Accessories

Beyond garments, laser cutting drives innovation in jewelry and fashion accessories.

Acrylic Jewelry: Lightweight earrings and necklaces with intricate designs.

Metal Accents: Fiber lasers cut thin metals for charms and fasteners.

Hybrid Designs: Combining fabric, acrylic, and metal for unique statements.

Accessories made with laser cutters often stand out for their detail and originality.

Sustainability in Fashion

The fashion industry faces pressure to become more sustainable, and laser cutting helps:

Reduced Waste: Tight nesting of patterns maximizes fabric use.

No Tooling Waste: Unlike die cutting, no molds or blades are discarded.

Eco-Friendly Materials: Designers experiment with biodegradable fabrics.

This aligns with consumer demand for greener fashion choices.

High Fashion Meets Mass Market

Luxury designers showcase laser-cut gowns and footwear on runways, while mass-market brands adopt the same technology for affordability. From haute couture to everyday streetwear, laser cutting bridges both ends of the fashion spectrum.

Questions & Answers

Q1: What fabrics can be laser cut in fashion?

A: Cotton, silk, polyester blends, felt, and many synthetics cut cleanly with lasers.

Q2: Why is laser cutting used on leather?

A: It produces sharp cuts and allows detailed engraving for customization.

Q3: Is laser cutting sustainable in fashion?

A: Yes. It reduces fabric waste and supports the use of eco-friendly materials.

Q4: Do luxury designers use laser cutting?

A: Absolutely. Many couture pieces now feature intricate laser-cut patterns.

Q5: Can accessories be made with laser cutting?

A: Yes. Jewelry, belts, bags, and shoes all benefit from laser-cut details.

😂 Silly Season Swag: Funny Laser-Cut Wine Charms and Gag Gift Boxes

😂 Silly Season Swag: Funny Laser-Cut Wine Charms and Gag Gift Boxes

The laser cutter isn't just for elegant keepsakes; it's a fantastic tool for creating unique, humorous, and irreverent items perfect for lighthearted holiday fun. Gag gifts and witty accessories are quick to make, easy to personalize, and are fantastic impulse buys.

This article focuses on using the laser for these fun, non-traditional Christmas projects.

I. Witty Accessories for Holiday Parties

Add some laughter to your gathering with personalized accessories that break the ice.

Funny Wine/Drink Charms: These are fast to cut and engrave from small scraps of acrylic or thin wood. Engrave short, humorous phrases that relate to the season or drinking culture, such as "Stole Santa's Wine" or "Ho Ho Hold My Beer".

Sarcastic Coasters: Design a set of engraved slate or wood coasters with witty sayings about holiday stress or famous Christmas movie quotes. These are a great way to use up 4x4-inch material squares.

Bad Santa Trophies: Create a tongue-in-cheek "award" for the "Worst Gift Giver" or "Ugliest Sweater" using cheap, bright acrylic and a simple layered design. These can be designed with a simple Laser Cut Trophy SVG

II. Custom Gag Gift Presentation

Make the packaging of an awful or hilarious gift part of the joke.

Laser-Cut "Coal" Boxes: Create a small, black-painted wooden box engraved with a naughty list name and fill it with literal coal lumps or charcoal briquettes

Puzzle Gift Card Holders: Design a simple laser-cut box with a clear acrylic window that requires the recipient to solve a small, interlocking puzzle before they can retrieve the gift card inside. Look for Laser Cut Gift Card Holders files that incorporate slots or screws (Source: Laser Cut Gift Card Holders - Etsy).

"Emergency" Kits: Engrave small wooden boxes to look like an official "Emergency Christmas Survival Kit" or "Break in Case of Holiday Stress" box. The box can be filled with mini liquor bottles, chocolate, or pain relievers.

III. Novelty and Prank Items

Faux Mistletoe: Cut a simple wooden mistletoe shape from thin wood and engrave a humorous message on it, like "Kiss Me, I'm Desperate" (Source: Christmas Mistletoe Sign Laser Cut File - Etsy).

Ugly Sweater Accessories: Cut out miniature ugly sweater shapes from wood and engrave them with truly awful holiday graphics. These can be used as magnets or small pins

📈 From Hobby to Holiday Hype: Top 5 Bestselling Christmas Items for Your Etsy Shop

📈 From Hobby to Holiday Hype: Top 5 Bestselling Christmas Items for Your Etsy Shop

Turning your laser hobby into a holiday business requires focusing on products that are high-demand, easy to personalize, and simple to ship. Etsy, in particular, rewards unique, high-quality, and customizable items.

Here are the top 5 bestselling laser-cut Christmas items that drive high sales volume:

1. Personalized Family Name Ornaments

Why they sell: They are a timeless keepsake that people buy every year for their own families or as gifts. High demand means you can run a single file with minor text changes for high efficiency.

Best Sellers: [suspicious link removed] (Source: Etsy), Family Name Plaques (circular or rectangular), and designs featuring the year

Material: Thin Baltic Birch plywood (1/8" or 3mm) is inexpensive, ships flat, and is easy to paint or stain.

2. Custom Engraved Cutting Boards

Why they sell: They are high-value gifts perfect for housewarmings, weddings, and couples. They offer a large surface area for detailed personalization (e.g., family recipes or crests).

Best Sellers: Walnut and Bamboo Charcuterie Boards engraved with "The [Family Name] Est. [Year]" (Source: Etsy) or a custom handwritten recipe.

Material: Maple, Walnut, or Bamboo (Bamboo is cost-effective but requires lower power to avoid scorching).

3. Christmas Village & Nativity Scene Kits

Why they sell: These offer a multi-part assembly project that appeals to both kids and adults. Selling them as kits allows for flat-pack shipping, which drastically reduces costs.

Best Sellers: 3D Wooden Christmas Village House Sets (Source: Etsy) or layered Nativity Scene sets

Material: MDF or 3mm plywood, allowing pieces to slot together tightly without glue (often called "tab and slot" designs).

4. Personalized Gift Tags

Why they sell: They are a great, low-cost impulse buy or an easy add-on sale for existing ornament orders. They use up scrap wood and acrylic efficiently.

Best Sellers: Tags cut into shapes like reindeer, snowflakes, or simple script names

Material: Scrap acrylic or 1/8" plywood.

5. Engraved Faux Leather/Cork Coasters

Why they sell: Coasters are highly practical and easy to batch-process in large numbers (sets of 4 or 6). Faux leather provides high-contrast engraving that looks premium.

Best Sellers: Faux Leather Coasters with a single holiday graphic (Source: Etsy) or personalized family name and initial designs.

Material: Faux Leather (Leatherette) or Cork (very fast and clean to engrave).

The next article idea is: Silly Season Swag: Funny Laser-Cut Wine Charms and Gag Gift Boxes.

💻 Design Like a Pro: Creating Seamless SVG Ornament Files in LightBurn

💻 Design Like a Pro: Creating Seamless SVG Ornament Files in LightBurn

For those selling laser-cut items or seeking professional-grade results, mastering the design software is essential. LightBurn is one of the most popular programs for laser control, offering powerful vector editing tools necessary for creating clean, perfectly interlocking ornament files.

This article focuses on the key steps and features within LightBurn needed to design a seamless, ready-to-cut ornament.

I. Understanding the File Format: SVG

Why SVG? Scalable Vector Graphics (SVG) files are the standard for laser cutters because they use mathematical paths rather than pixels. This allows you to scale the ornament to any size without losing sharpness or detail.

Vector vs. Engrave: Ensure the outer boundary of your ornament and any internal cutouts are defined as Vector Paths (set to "Line" or "Cut" in LightBurn) and not raster images (set to "Fill" or "Engrave").

II. Essential LightBurn Tools for Ornament Design

These tools ensure your ornament is structurally sound and easy to assemble:

Offset Tool: Critical for creating clean borders, internal mats, or ensuring parts fit together. If you want a decorative border around an engraved name, use the Offset Tool to generate a perfect path around the text

Boolean Tools (Weld, Subtract, Intersect): These are vital for creating complex shapes from simple ones.

Use Weld (Union) to combine two shapes into one seamless piece, such as merging a hanger hole onto the top of a reindeer silhouette.

Use Subtract (Difference) to cut one shape completely out of another, such as carving a name or a slot out of a background shape

The Kerf Adjustment: If you are designing layered or interlocking ornaments, the Kerf Offset feature in LightBurn is essential. Kerf is the tiny amount of material the laser vaporizes away during the cut. Adjusting the kerf compensates for this loss, ensuring interlocking tabs fit tightly without sanding or glue

III. Creating the Perfect Hanger Hole

Size: A 3mm to 4mm hole is generally sufficient for threading ribbon or twine.

Placement: Use the Center Point feature to ensure the hole is centered horizontally on the ornament's strongest upper point. This prevents the finished ornament from hanging crookedly on the tree (Source: [suspicious link removed]).

Final Check: Use the Preview Window (often accessed by clicking the monitor icon) before saving or cutting. This shows you exactly how the laser will run, helping you catch any unclosed vector paths or overlaps (Source: Preview Window - LightBurn Software Documentation).

🎁 Beyond the Bow: Custom Laser-Cut Gift Tags and Presentation Boxes

🎁 Beyond the Bow: Custom Laser-Cut Gift Tags and Presentation Boxes

The presentation of a gift is often as memorable as the gift itself. Laser cutters are the ultimate tool for creating custom, professional-grade gift packaging, transforming simple paper goods and plain boxes into personalized holiday treasures.

This article focuses on using your laser to design and cut unique gift tags and structural presentation boxes.

I. The Art of the Custom Gift Tag

Moving beyond basic card stock, laser-cut tags are durable keepsakes that recipients often reuse as ornaments.

Materials: Thin Baltic Birch plywood (3mm or 1/8 inch) is ideal for sturdiness, offering a rustic look that can be painted or stained. For a modern aesthetic, colored or mirror acrylic works well and can be easily engraved with a permanent marker

Design Ideas:

Monogram Tags: Simple circular or rectangular tags engraved with a single large initial

Themed Scrollwork: Intricate tags cut in the shape of reindeer antlers, mistletoe, or decorative snowflakes

Two-Part Tags: Design a tag with a cutout that reveals a contrasting layer of colored cardstock or felt glued behind it, making the design truly pop.

II. Structural Presentation Boxes

Creating a custom box for a specialty item (like wine, jewelry, or a homemade candle) elevates the gift instantly.

Box Construction: Look for SVG or DXF files for laser-cut boxes that are designed using interlocking finger or slot joints (Source: [suspicious link removed]). These designs are cut from flat material and snap together without needing complex glue or fasteners.

Best Materials: MDF or thin plywood (3mm or 1/8 inch) are best for structural integrity. The joints will hold firmly, and the surface is easy to engrave for personalization.

Specialty Holders: Design specific internal inserts or dividers for fragile items. You can find files for a Laser Cut Wine Bottle Box SVG with a custom lid or a small, decorative Christmas-themed jewelry box (Source: Laser Cut Jewelry Box with Drawers - Etsy).

III. Finishing Touches for Impact

Engrave the Card: For boxes, use the laser to engrave the recipient's name or a heartfelt message directly onto the lid (Source: [suspicious link removed]).

Ribbon Slits: Design small, thin slots into the sides or top of the box to easily thread ribbon, eliminating the need for punching holes.

Use Draftboard: For temporary or extremely intricate boxes, Draftboard (low-cost MDF) is excellent for fast cutting and prototyping

Best Materials for CO₂ Laser Cutting and Engraving

Best Materials for CO₂ Laser Cutting and Engraving

Choosing the Right Material for Professional Results

Not every material reacts the same way to a laser beam. Some cut cleanly with perfect edges, while others burn, melt, or release unsafe fumes. Knowing which materials work best with CO₂ laser systems ensures precision, consistency, and safety—whether you’re creating signage, prototypes, or production components.

Top Materials for Laser Cutting

Acrylic (Cast and Extruded)

Cuts: Cleanly with flame-polished edges

Engraves: Smoothly with sharp contrast

Applications: Signage, awards, retail displays, lighting panels

Tip: Cast acrylic engraves better than extruded for crisp detail

Birch and Other Plywoods

Cuts: Cleanly with some edge darkening

Engraves: With excellent tonal range

Applications: Models, decor, product packaging, art pieces

Tip: Choose high-quality laser-safe ply—cheap alternatives may contain glue layers that burn inconsistently.

Hardwoods

Cuts: More slowly but with rich color and depth

Engraves: Dark, textured marks with high contrast

Applications: Custom furniture parts, signage, craft goods

Tip: Consistency varies by grain density—test before large runs.

Paperboard and Cardstock

Cuts: Quickly and accurately with minimal burn

Engraves: Subtly, perfect for pattern work

Applications: Packaging, stencils, invitations, prototypes

Tip: Use air assist to prevent edge scorching.

Leather (Genuine or Laser-Safe Synthetic)

Cuts: Cleanly with sealed edges

Engraves: With dark, high-contrast surface markings

Applications: Branding, accessories, signage, decor

Tip: Only cut verified laser-safe synthetics—PVC or vinyl-based materials are unsafe.

Delrin (Acetal)

Cuts: With smooth, durable edges

Engraves: Precisely without residue

Applications: Mechanical parts, jigs, and gaskets

Tip: Emits a mild odor when cut—use proper ventilation.

Materials to Avoid

Some materials release toxic fumes or damage the machine:

PVC and Vinyl: Produce corrosive chlorine gas

Polycarbonate: Discolors, melts, and emits harmful smoke

ABS Plastic: Melts and gives off cyanide gas

Fiberglass: Burns unpredictably and ruins optics

If unsure, always confirm your material’s safety with a technician before cutting.

How American Laser Cutter Handles Materials

We cut and engrave a wide range of laser-safe materials daily, from acrylic and wood to specialty plastics. Clients are welcome to supply their own material or choose from our in-house selection. Each job runs on calibrated CO₂ lasers with power levels optimized for clarity, edge quality, and minimal residue.

Conclusion

Selecting the right material is critical for quality, safety, and appearance. Acrylic delivers precision and clarity, while wood provides texture and warmth—each suited to specific creative goals.

For professional cutting and engraving across multiple materials, American Laser Cutter can help—on-site in Los Angeles or remotely anywhere in the U.S.

Email americanlaserco@gmail.com or visit americanlaserco.com to start your next project.

🧣 Elegant Etchings: Personalized Leather and Felt Stockings

🧣 Elegant Etchings: Personalized Leather and Felt Stockings

Laser cutting and engraving are perfect for creating custom Christmas stockings and tags that become cherished, long-lasting keepsakes. Instead of temporary vinyl or embroidery, a laser creates a permanent, high-contrast mark that adds a premium feel to soft goods.

This article focuses on using the laser for both personalization and construction.

I. The Power of Personalized Tags (Faux Leather)

Faux leather (often called leatherette) is the ideal material for engraving names and designs, as it provides sharp contrast and is durable.

Why Faux Leather? Unlike genuine leather, laser-safe faux leather (free of PVC/vinyl) is inexpensive, cuts cleanly, and often reveals a metallic or light-colored layer underneath the surface when engraved. For instance, the engraving on the popular Rustic/Dark Faux Leather often comes out in a gorgeous gold or silver color, providing high contrast (Source: Personalized Christmas Stocking Tags - Leather Tags - APKhome).

The Project: Create Personalized Faux Leather Stocking Tags that are cut to size (e.g., 5" x 2") and include a grommet and cord for hanging (Source: Personalized Christmas Stocking Tags - Custom Laser Engraved Faux Leather Name Tags With Hanging Cord).

Best Practice: When engraving, the laser creates a dark mark by burning the surface material. Use masking tape around the design area to protect the leather from soot and charring (Source: [suspicious link removed]).

II. Creating Custom Felt Stockings

Felt is a versatile material for laser cutting. It can be used to cut the entire stocking shape or delicate appliqué pieces.

The Material: 100% Polyester Felt is highly recommended for laser cutting. The laser cleanly seals the edges as it cuts, preventing fraying, which is a common problem with traditional cutting methods (Source: Make your own laser cut felt Christmas boot. USA).

Felt Appliqué: The quickest method is to cut out intricate designs—like snowflake shapes, animal silhouettes, or letters—from colored felt using your laser and then sewing or gluing them onto a pre-made stocking.

The Cut: You can use an SVG laser cut file to create an entire miniature stocking gift card holder or a full-sized stocking shape from 4mm felt (Source: Laser Cutting Felt Stockings - YouTube).

III. Direct Engraving on Stockings

If you have a flat-bed laser and a coated fabric stocking, you can engrave directly onto the material for a crisp, permanent result.

Testing is Key: Only attempt this on smooth-surfaced, coated fabrics or faux leather stockings. Avoid velvet or shaggy felt, as these materials can be damaged or melted by the laser (Source: How to Personalize a Christmas Stocking: The Ultimate Guide 2026 - LaserPecker).

Flatness: Ensure the stocking is laid perfectly flat and secured in your laser bed to prevent the laser head from catching the material during the job (Source: [suspicious link removed]).

💡 Illuminating the Holidays: Laser Engraving Acrylic for Custom LED Night Lights

💡 Illuminating the Holidays: Laser Engraving Acrylic for Custom LED Night Lights

Laser-engraved acrylic lamps are a fantastic way to create a modern, glowing piece of holiday decor or a highly personalized gift. The technique, known as edge-lighting, works by engraving a design onto a clear acrylic panel. When the LED base shines light up into the edge of the panel, the light travels through the material and illuminates only the frosted, engraved lines, creating a striking 3D illusion.

Here is a guide to creating these custom acrylic night lights:

I. Choosing Your Materials

The type of acrylic you choose is the single most important factor for success.

Acrylic Type: Always use Cast Acrylic (PMMA) for engraving (Source: Cast Clear Acrylic Sheet for Laser Cutting & Engraving - 1/16 - MakerStock). Cast acrylic produces a beautiful frosted, white engraving that contrasts perfectly with the clear material, which is necessary for the lighting effect. Extruded acrylic tends to melt and result in a less visible, transparent mark (Source: Laser Engraving on Acrylic: The Art of Transparency).

Thickness: 3mm (1/8 inch) clear acrylic is ideal, as it is durable yet thin enough to fit most commercially available USB Wood Lampholders with Built-in LED Bases (Source: How to Make an Acrylic Laser Cut Lamp – Easy DIY Project - OneLaser).

LED Base: Purchase a premade wooden or plastic LED Light Base (Source: Led Base Laser File - Etsy) that has a slot sized to accept your acrylic's thickness.

II. The Laser Engraving Process

The goal is to engrave the design on the back side of the acrylic for a smoother finish and better light effect.

Prepare the Design: Create or import your Christmas design (e.g., a family portrait, a snowman, or a festive quote).

Mirror the Image: Before engraving, mirror the entire design horizontally (Source: How to Laser Engrave an Acrylic Night Light- easy Money $$ with your Thunder Laser - YouTube). This ensures that when you engrave the back, the image will appear correctly oriented and smooth when viewed from the front.

Engrave First, Then Cut: Run the engraving job first using high speed and low power to achieve a frosted finish without melting the acrylic. Then, cut the outline of your shape (including the tab that fits into the base) (Source: How to Laser Cut Light with 4 Easy Steps - OneLaser).

Tip for Diode Lasers: If you are using a lower-power diode laser, which may struggle with clear materials, you can coat the engraving area with a black marker or use a piece of black cardstock underneath the acrylic to help the laser absorb light and etch the surface (Source: Clear Acrylic Laser Engraving Guide: Tips, Tools & Project Ideas - LaserPecker).

III. Final Assembly

No glue is needed if your tab and base slot are matched correctly.

Clean the Panel: Peel off any protective film and clean the acrylic gently using a soft cloth and isopropyl alcohol to remove dust and residue.

Insert and Light Up: Slide the tab on the acrylic panel into the slot on your LED base (Source: How to Laser Cut Light with 4 Easy Steps - OneLaser). Plug in the base to see your design illuminated!

Laser Cutting for Packaging — Precision Meets Branding

Packaging has always been more than a container. It’s the first impression of a product, the physical extension of a brand. In 2025, laser cutting is transforming how companies design, prototype, and produce packaging. From intricate cutouts to custom inserts, laser technology enables packaging that is both functional and visually striking.

Why Use Laser Cutting for Packaging

Traditional packaging methods often require expensive tooling or dies. Laser cutting removes that barrier.

Cost-Effective for Short Runs: No tooling means small quantities are affordable.

Rapid Prototyping: Brands can test and refine designs quickly.

High Precision: Logos, patterns, and shapes are cut cleanly.

Customization: Personalized packaging for limited editions or events.

Types of Laser-Cut Packaging

Custom Boxes

Cardboard and paperboard are ideal for laser cutting. Companies can create unique structural designs with windows, slots, and decorative edges.

Inserts and Liners

Foam, cardboard, or felt inserts cut by lasers protect fragile products while fitting perfectly to the item’s shape.

Decorative Elements

Patterns cut into sleeves or box tops add luxury appeal. Intricate detailing that once required costly embossing can now be achieved with a laser.

Materials for Packaging

Cardboard and Paper: Lightweight, affordable, and recyclable.

Acrylic: Used for luxury boxes and retail displays.

Foam: Perfect for inserts that hold items securely.

Fabrics: Occasionally used for decorative packaging covers.

Each material has its own cutting settings, but all benefit from the precision of lasers.

Branding Advantages

Laser cutting allows packaging to double as a marketing tool:

Logo Integration: Directly cut into or engraved on the packaging.

Personalization: Names or messages for special events or customers.

Limited Editions: Unique packaging that differentiates seasonal or promotional products.

In competitive markets, packaging that stands out can make the difference between being noticed and being overlooked.

Environmental Considerations

Eco-conscious packaging is a growing priority. Laser cutting supports this by:

Reducing waste through precise nesting of shapes.

Enabling the use of recyclable and biodegradable materials.

Eliminating the need for additional dyes or inks in many cases.

This makes laser cutting appealing to brands that want sustainability to be part of their identity.

Questions & Answers

Q1: Why is laser cutting good for packaging prototypes?

A: It allows rapid iteration without tooling costs, letting brands test designs quickly.

Q2: Can lasers cut both paper and foam for inserts?

A: Yes, with proper settings, lasers handle cardboard, paperboard, and foam for secure product packaging.

Q3: How does laser packaging help with branding?

A: Logos, cutouts, and custom designs enhance the visual impact and reinforce brand identity.

Q4: Is laser-cut packaging eco-friendly?

A: It can be, especially when using recyclable materials and minimizing waste through precise cuts.

Q5: What industries use laser-cut packaging most?

A: Retail, cosmetics, electronics, luxury goods, and food packaging all benefit from laser customization.

🏡 Laser-Cut Gingerbread Houses: A Step-by-Step Guide to Building Your Edible Masterpiece

🏡 Laser-Cut Gingerbread Houses: A Step-by-Step Guide to Building Your Edible Masterpiece

Laser cutting offers a fun, clean way to create a structural, permanent gingerbread house that can be reused year after year. By using materials like wood or acrylic, you eliminate the stress of crumbling walls and uneven baking, replacing them with precision-cut, easy-to-assemble pieces.

This article details how to leverage your laser cutter for this traditional holiday project, focusing on wood kits that can be decorated like real gingerbread.

I. Materials for Your Faux Gingerbread House

Instead of dough, you'll be using durable, easy-to-decorate materials:

Plywood or MDF: These are the most common and cost-effective materials. Most digital files are designed for common thicknesses like 3mm (1/8 inch) or 4mm (Source: Laser Cut Ginger Bread Christmas Village Houses Glowforge - Design Bundles). Plywood offers a natural look that mimics the golden-brown color of baked gingerbread.

Acrylic: For a modern, stylized look, use acrylic or plexiglass (Source: Holiday Gingerbread House Laser Cut - Svg Ocean). White or clear acrylic pieces can be decorated with bright vinyl or paint markers.

Lights: Many digital plans include a cutout or opening to fit a battery-operated tea light or string lights (Source: Gingerbread House Laser SVG files - So Fontsy), turning the house into a festive nightlight.

II. The Laser Cutting Process

The key to a successful structural project is accuracy, especially with the connecting tabs and slots.

Design Files: Look for SVG or DXF files specifically labeled for laser cutting. Many marketplaces offer individual 3D Gingerbread House files or complete Christmas Village Gingerbread House Bundle sets (Source: Gingerbread Laser Cut Files Svg - Etsy).

Check Material Thickness: Always use the slot tester file included with your digital design (if available) to ensure the file's slot widths match the exact thickness of your wood. If they don't, you may need to adjust the slot size in your design software to ensure a tight fit (Source: Gingerbread House Laser SVG files - So Fontsy).

Scoring for Decoration: When processing the walls, use the Score function (a light etch) to create the "icing" or "shutter" details onto the walls. This provides an outline for painting or decorating later.

III. Assembly and Decoration

For wood or acrylic kits, you'll replace edible icing with permanent adhesive and decorative sealants.

Assembly: Use strong wood glue or CA glue to secure the tab-and-slot joints. Kits designed with interlocking pieces should slot together easily, but glue ensures permanence. If your material is MDF, MDF Laser Cut Gingerbread House Kits often slot together for easy assembly (Source: MDF Laser Cut Gingerbread House Kit Christmas Craft Kit 3d Build Your Own | eBay).

The "Icing" Effect: Use white caulk or a thick white paint (like dimensional paint) applied with a piping bag to mimic the look of royal icing along the roofline, window frames, and seams.

Candy Decoration: Glue on small plastic or wood cutouts, beads, or other decorative elements (Source: LASER CUT FAUX GINGERBREAD HOUSE FROM CARDBOARD - YouTube). For a truly permanent decoration, look for gingerbread man SVG paint kits that can be laser-cut from wood and painted before being attached to the house (Source: Lasercut Gingerbread - Etsy).

Best Materials for CO₂ Laser Cutting and Engraving

Best Materials for CO₂ Laser Cutting and Engraving

Choosing the Right Material for Professional Results

Not every material reacts the same way to a laser beam. Some cut cleanly with perfect edges, while others burn, melt, or release unsafe fumes. Knowing which materials work best with CO₂ laser systems ensures precision, consistency, and safety—whether you’re creating signage, prototypes, or production components.

Top Materials for Laser Cutting

Acrylic (Cast and Extruded)

Cuts: Cleanly with flame-polished edges

Engraves: Smoothly with sharp contrast

Applications: Signage, awards, retail displays, lighting panels

Tip: Cast acrylic engraves better than extruded for crisp detail

Birch and Other Plywoods

Cuts: Cleanly with some edge darkening

Engraves: With excellent tonal range

Applications: Models, decor, product packaging, art pieces

Tip: Choose high-quality laser-safe ply—cheap alternatives may contain glue layers that burn inconsistently.

Hardwoods

Cuts: More slowly but with rich color and depth

Engraves: Dark, textured marks with high contrast

Applications: Custom furniture parts, signage, craft goods

Tip: Consistency varies by grain density—test before large runs.

Paperboard and Cardstock

Cuts: Quickly and accurately with minimal burn

Engraves: Subtly, perfect for pattern work

Applications: Packaging, stencils, invitations, prototypes

Tip: Use air assist to prevent edge scorching.

Leather (Genuine or Laser-Safe Synthetic)

Cuts: Cleanly with sealed edges

Engraves: With dark, high-contrast surface markings

Applications: Branding, accessories, signage, decor

Tip: Only cut verified laser-safe synthetics—PVC or vinyl-based materials are unsafe.

Delrin (Acetal)

Cuts: With smooth, durable edges

Engraves: Precisely without residue

Applications: Mechanical parts, jigs, and gaskets

Tip: Emits a mild odor when cut—use proper ventilation.

Materials to Avoid

Some materials release toxic fumes or damage the machine:

PVC and Vinyl: Produce corrosive chlorine gas

Polycarbonate: Discolors, melts, and emits harmful smoke

ABS Plastic: Melts and gives off cyanide gas

Fiberglass: Burns unpredictably and ruins optics

If unsure, always confirm your material’s safety with a technician before cutting.

How American Laser Cutter Handles Materials

We cut and engrave a wide range of laser-safe materials daily, from acrylic and wood to specialty plastics. Clients are welcome to supply their own material or choose from our in-house selection. Each job runs on calibrated CO₂ lasers with power levels optimized for clarity, edge quality, and minimal residue.

Conclusion

Selecting the right material is critical for quality, safety, and appearance. Acrylic delivers precision and clarity, while wood provides texture and warmth—each suited to specific creative goals.

For professional cutting and engraving across multiple materials, American Laser Cutter can help—on-site in Los Angeles or remotely anywhere in the U.S.

Email americanlaserco@gmail.com or visit americanlaserco.com to start your next project.

10 Everyday Objects You Didn’t Know Were Laser Cut

When people think of laser cutting, they often picture industrial parts or custom signage. But in reality, lasers shape many of the objects we interact with daily. From packaging to furniture, laser cutters leave their invisible signature everywhere. Here are ten surprising items that often come from a laser.

1. Greeting Cards

Many premium greeting cards use laser-cut details for lace-like edges or pop-up features. The precision adds elegance and uniqueness that regular die cutting can’t match.

2. Jewelry and Accessories

Lightweight earrings, pendants, and even watch straps often start with laser-cut acrylic or metal. The detail possible makes designs both fashionable and affordable.

3. Phone Cases

Custom wood or acrylic phone cases frequently feature laser-engraved logos, patterns, or cutouts. It’s how small brands create boutique products without mass manufacturing.

4. Furniture Accents

From intricate chair backs to decorative lamp shades, furniture often incorporates laser-cut wood or metal components. Designers rely on lasers for repeating patterns and consistency.

5. Packaging Inserts

That perfectly shaped foam or cardboard insert in electronics boxes? Often laser cut for a snug, protective fit. It ensures your gadgets arrive safely.

6. Clothing Details

Some high-end fashion items use laser cutting to create fabric cutouts, logos, or distressed textures on denim and leather. It’s a precise, modern version of tailoring.

7. Home Décor

Wall art, coasters, mirrors, and clocks often use laser cutting for shapes and engraved designs. Even stores like IKEA include laser-cut elements in décor lines.

8. Toys and Puzzles

Wooden puzzles, board game pieces, and even dollhouse furniture often rely on laser cutting for accuracy and safety. It ensures smooth edges without splinters.

9. Musical Instruments

Some guitar inlays, drum shells, and wooden instrument parts are laser cut for precision. Even custom picks can be engraved with logos or text.

10. Kitchenware

From engraved cutting boards to stainless steel utensils, laser technology adds both function and personalization. Brands use it to mark logos, recipes, or designs.

Questions & Answers

Q1: Are greeting cards really laser cut?

A: Yes, premium cards often use lasers for lace-like designs or pop-up structures.

Q2: How does laser cutting appear in furniture?

A: It creates decorative panels, lamp shades, and repeatable patterns.

Q3: Why use laser cutting for packaging?

A: Foam and cardboard inserts can be customized quickly for snug fits.

Q4: Do musical instruments use lasers?

A: Yes, especially for inlays, shell cuts, and decorative engraving.

Q5: What’s the biggest benefit of lasers in everyday objects?

A: Precision, consistency, and the ability to make unique designs affordably.

Laser Cutting in Education — Teaching Design and Innovation

Laser cutting isn’t just for businesses or hobbyists. Schools, universities, and makerspaces are adopting it as a tool for teaching creativity, engineering, and problem solving. By giving students hands-on experience with design-to-production workflows, laser cutting helps bridge the gap between theory and practice.

Why Laser Cutting Matters in Education

Education is increasingly focused on real-world skills. Laser cutting teaches students to:

Translate digital designs into physical objects.

Understand material properties and limitations.

Apply STEM concepts in a practical way.

Work iteratively, testing and refining ideas quickly.

This combination of technical and creative learning makes laser cutters valuable in classrooms across disciplines.

How Schools Use Laser Cutting

STEM Programs

Engineering and technology classes use laser cutters to build models, test mechanisms, and design prototypes. Students learn CAD skills alongside fabrication.

Art and Design

Graphic design and fine arts programs use lasers for engraving, stencils, and custom pieces. It expands creative possibilities while teaching digital design tools.

Architecture

Laser cutters allow students to create scale models with precise details, enhancing their understanding of structural design.

Makerspaces

Community and school makerspaces give students access to equipment they wouldn’t normally afford, encouraging experimentation and entrepreneurship.

Benefits for Students

Immediate Feedback: Students see their designs come to life in minutes.

Collaboration: Group projects encourage teamwork and shared problem solving.

Confidence Building: Success in making tangible projects boosts motivation.

Career Readiness: Prepares students for industries that already rely on digital fabrication.

Challenges in Education

While valuable, laser cutting in schools comes with challenges:

Cost of Equipment: Industrial machines can be expensive.

Maintenance: Machines require regular upkeep and calibration.

Safety: Proper training and ventilation are essential.

Curriculum Integration: Teachers must align projects with learning goals.

The Future of Laser Cutting in Education

As costs come down, more schools are likely to adopt laser cutters. Advances in user-friendly software and safer machine designs will make them even more accessible. Future trends include cloud-based design sharing, AI-optimized workflows, and integration with 3D printing for hybrid learning experiences.

Questions & Answers

Q1: Why should schools invest in laser cutting?

A: It builds practical skills in design, engineering, and creativity while preparing students for modern industries.

Q2: What subjects benefit most from laser cutting?

A: STEM, art, design, and architecture programs benefit the most.

Q3: Is laser cutting safe for students?

A: Yes, when machines are enclosed, properly ventilated, and students receive safety training.

Q4: How expensive is it for schools?

A: Desktop machines can be a few thousand dollars, while industrial systems cost more but can be shared in makerspaces.

Q5: What’s next for laser cutting in education?

A: Expect wider adoption, AI-driven design tools, and integration with other digital fabrication technologies.

DIY Laser Cutting

DIY Laser Cutting: The Ultimate Hands-On Fabrication Experience

For makers, artists, and engineers who prefer to keep their hands on the controls, American Laser Cutter offers a premier DIY laser cutting experience in the heart of Los Angeles. While many fabrication shops require you to hand off your files and wait days for a result, our workshop is built on the philosophy of open access: you design it, you cut it.

Why Choose DIY Over Full-Service?

Doing it yourself isn't just about saving money—it's about creative control.

Instant Iteration: Did your prototype come out 1mm too wide? In a DIY session, you can adjust your vector file and cut a corrected version immediately, saving weeks of back-and-forth emails.

Precision Tweaking: You have full control over speed and power settings. Whether you want a deep, dark engraving or a light surface mark, you can test and dial in the perfect look on the fly.

Speed: No queues. No rush fees. Just book your slot, show up, and get to work.

Professional Tools for Personal Projects

"DIY" doesn't mean "amateur equipment." When you rent time at our studio, you are using the same industrial machinery used by professional prop studios and architectural firms.

High-Power Systems: Our 100W+ CO₂ lasers cut faster and cleaner than home-grade diode lasers, easily slicing through 1/4" acrylic or 3/8" plywood.

Massive Work Area: With 48" x 60" cutting beds, you aren't limited to small trinkets. You can fabricate full-scale furniture parts, large signage, or entire costume armor sets in one go.

Industry-Standard Software: We use LightBurn, giving you robust control over your layers and cut paths.

What You Need to Get Started

We make the process simple for first-time users:

Orientation: All new DIYers complete a mandatory safety check to learn the machine basics and shop rules.

Files: Bring your designs in .AI, .DXF, or .PDF format.

Materials: Bring your own laser-safe materials (wood, paper, acrylic, leather) or purchase stock from us on-site. Strictly no PVC or Vinyl.

Visit Our Workshop

Take your projects into your own hands. Whether you are a student finishing a model or a startup building a prototype, our DIY laser cutting service gives you the power to create on your terms.

Address: 1319 South Los Angeles St, Los Angeles, CA 90015

Book Your Session: americanlaserco@gmail.com | 213-866-4738

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)