Foam Board Laser Cutter

If you’re searching for a foam board laser cutter in Los Angeles, American Laser Cutter is your local source for precise, professional cutting services. Foam board is a lightweight, versatile material perfect for displays, models, signage, and creative projects—and laser cutting makes it possible to achieve detail and accuracy that hand-cutting can’t match. Our Downtown Los Angeles workshop provides fast, consistent results for businesses, designers, students, and DIY makers.

Why Use a Laser Cutter for Foam Board?

Foam board is widely used for both professional and creative projects, but cutting it by hand often results in uneven edges or wasted material. A laser cutter offers clear advantages:

Precision – Achieve sharp edges, fine details, and repeatable cuts.

Speed – Complete multiple pieces quickly and efficiently.

Consistency – Every piece comes out identical, even in high-volume runs.

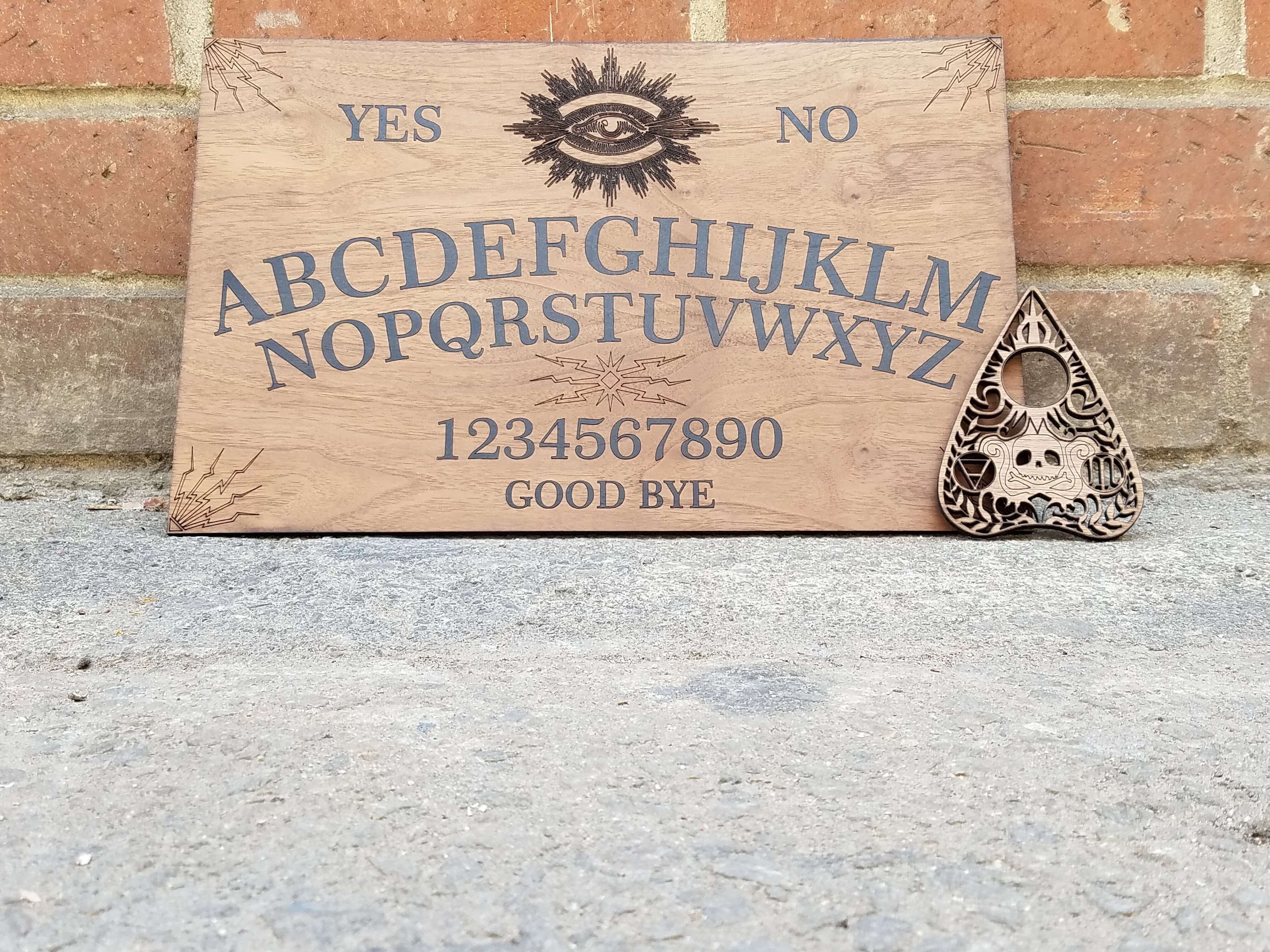

Versatility – Works for lettering, displays, stencils, and 3D structures.

Professional Finish – Smooth edges for clean presentation quality.

Popular Uses for Laser-Cut Foam Board

Our foam board cutting service is used in a wide range of industries and applications, including:

Architectural Models – Detailed layouts and structural components.

Event & Retail Displays – Signage, branding elements, and custom shapes.

Educational Projects – School and university presentations.

Prototyping – Low-cost, fast iterations for design testing.

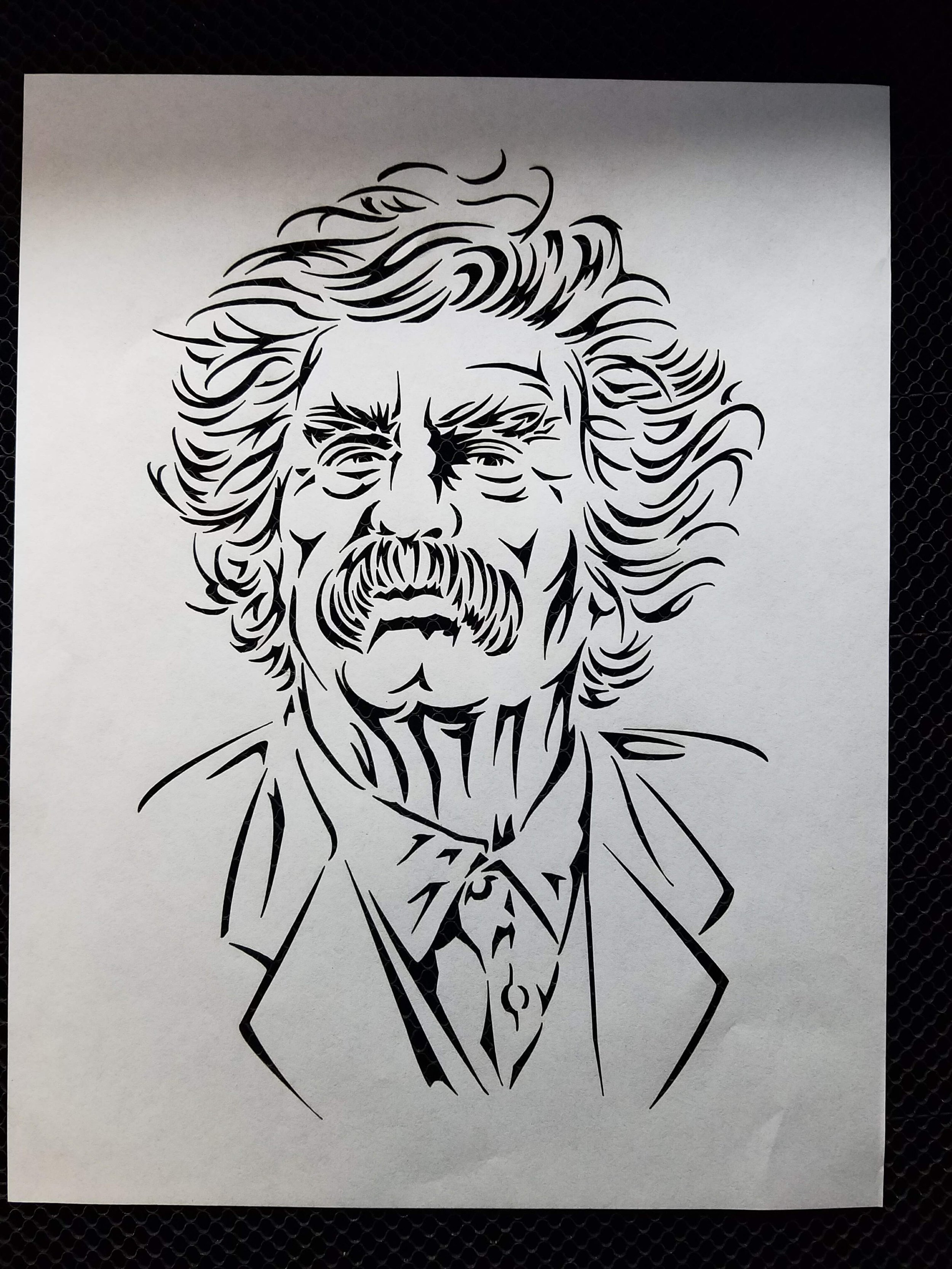

Art & Craft – Layered artwork, stencils, and decorative projects.

How Foam Board Cutting Works

At American Laser Cutter, the process is simple and streamlined:

Prepare Your File – Save your design in AI, DXF, or PDF format.

Provide Your Material – Clients may supply their own laser-safe foam board sheets.

Cutting & Pickup – We laser cut your project in our Downtown Los Angeles workshop.

All visits are by appointment only, ensuring your project receives focused attention.

Things to Know About Laser Cutting Foam Board

Best Thickness – Standard 3/16" foam board works well for most projects.

Edge Finish – Cutting may slightly darken the edges, which can add contrast.

Material Safety – Only laser-safe foam boards should be used—avoid coated boards that aren’t compatible.

Efficiency – Nesting designs can help save material and reduce costs.

Local Advantages with American Laser Cutter

Working with a Los Angeles-based foam board laser cutter means:

Quick Turnaround – No delays from shipping or out-of-state production.

Convenient Pickup – Located in Downtown LA for easy access.

Local Delivery Options – Available for businesses and events within the area.

Nationwide Shipping – USPS available for clients outside Los Angeles.

Start Your Foam Board Cutting Project Today

If you’ve been searching for a foam board laser cutter near me, American Laser Cutter is ready to help. Whether you’re preparing an architectural model, designing custom displays, or working on creative projects, our laser cutting service ensures precision and consistency every time.

The "Pop-Up Shop" Savior

Meet the User: Elena, a freelance illustrator and small business owner living in Echo Park. She’s prepping for her first big booth at a maker’s market in Downtown LA this weekend.

The Very Human Problem: Elena spent all her budget on inventory and forgot about her booth signage until three days before the event. In a panic, she tried to hand-cut her intricate script logo out of foam core using an X-Acto knife on her kitchen table. The result? A disaster. The edges were jagged, the foam was crushed in the corners, and it looked "crafty" in a bad way—definitely not professional enough to represent her brand.

How She Uses the Page:

The Relief: She googles "laser cutting foam board LA" and lands here. The first thing that calms her down is seeing "Downtown Los Angeles workshop". She realizes she can just drive the files over rather than praying for shipping to arrive on time.

The "Aha" Moment: She reads the section "Why Use a Laser Cutter?" and nods along to the point about "hand-cutting often results in uneven edges". That is exactly what she’s staring at on her kitchen table. She needs the "Professional Finish" promised on the site.

Managing Expectations: She notices the "Things to Know" section warns that "Cutting may slightly darken the edges". Instead of worrying, she realizes this will actually help her white logo pop against the white wall of her tent—a happy accident.

Taking Action: She sees that 3/16" foam board is the standard, which is exactly what she has. She hits "Get your product Laser cut", uploads her vector file, and drops off her own material later that afternoon.

The Happy Ending: Elena picks up her sign on Friday. It’s lightweight (easy to hang with tape), the curves of her logo are perfectly smooth, and she heads to her market feeling like a legit professional, not just someone with a hobby.