How to Cut Acrylic (Perspex) Sheet

Cutting acrylic (also called Perspex) cleanly requires the right method, sharp tooling, and heat control. If you want edges that are clear, parts that fit precisely, and consistent repeatability, laser cutting is the most reliable option. American Laser Cutter is a fabrication shop in Downtown Los Angeles specializing in accurate acrylic parts for prototypes, products, signage, and architectural components—delivered ready for assembly.

The Main Cutting Methods

Score & Snap: Works for thin sheets and straight lines. It’s inexpensive but prone to edge chips, stress cracks, and inconsistent dimensions.

Table Saw/Jig Saw: Fine-tooth blades help, yet heat buildup can melt edges and throw dust. Curves are limited and small features are difficult.

CNC Routing: Great for thicker stock but requires toolpaths and produces swarf. Inside corners need dog-bones; micro features are limited by bit size.

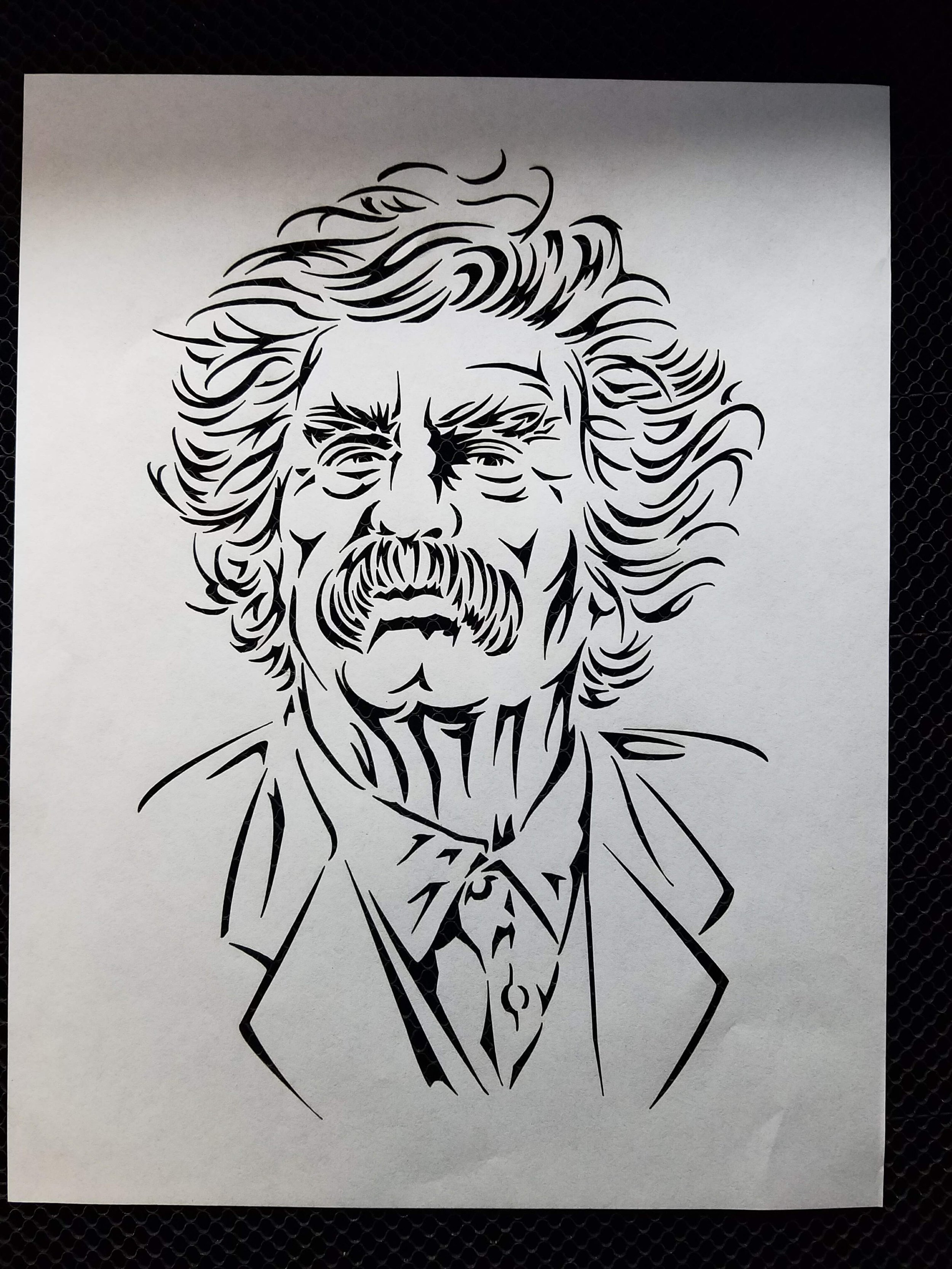

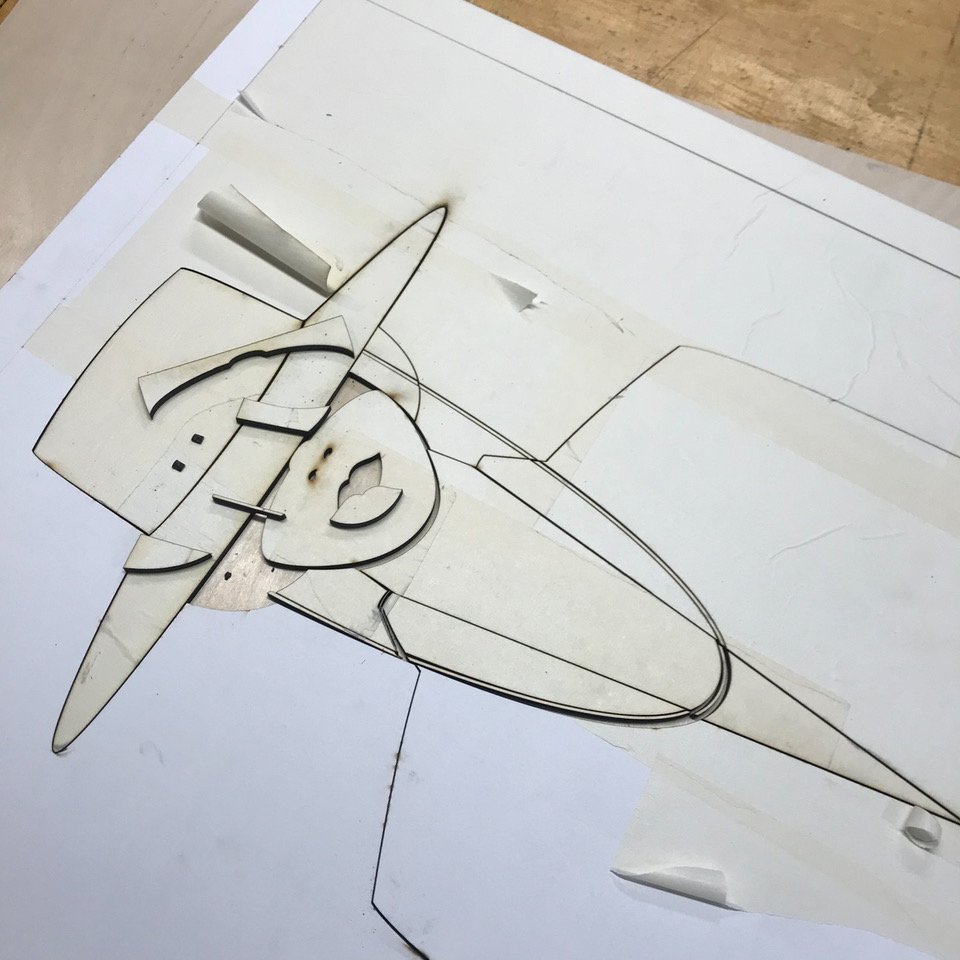

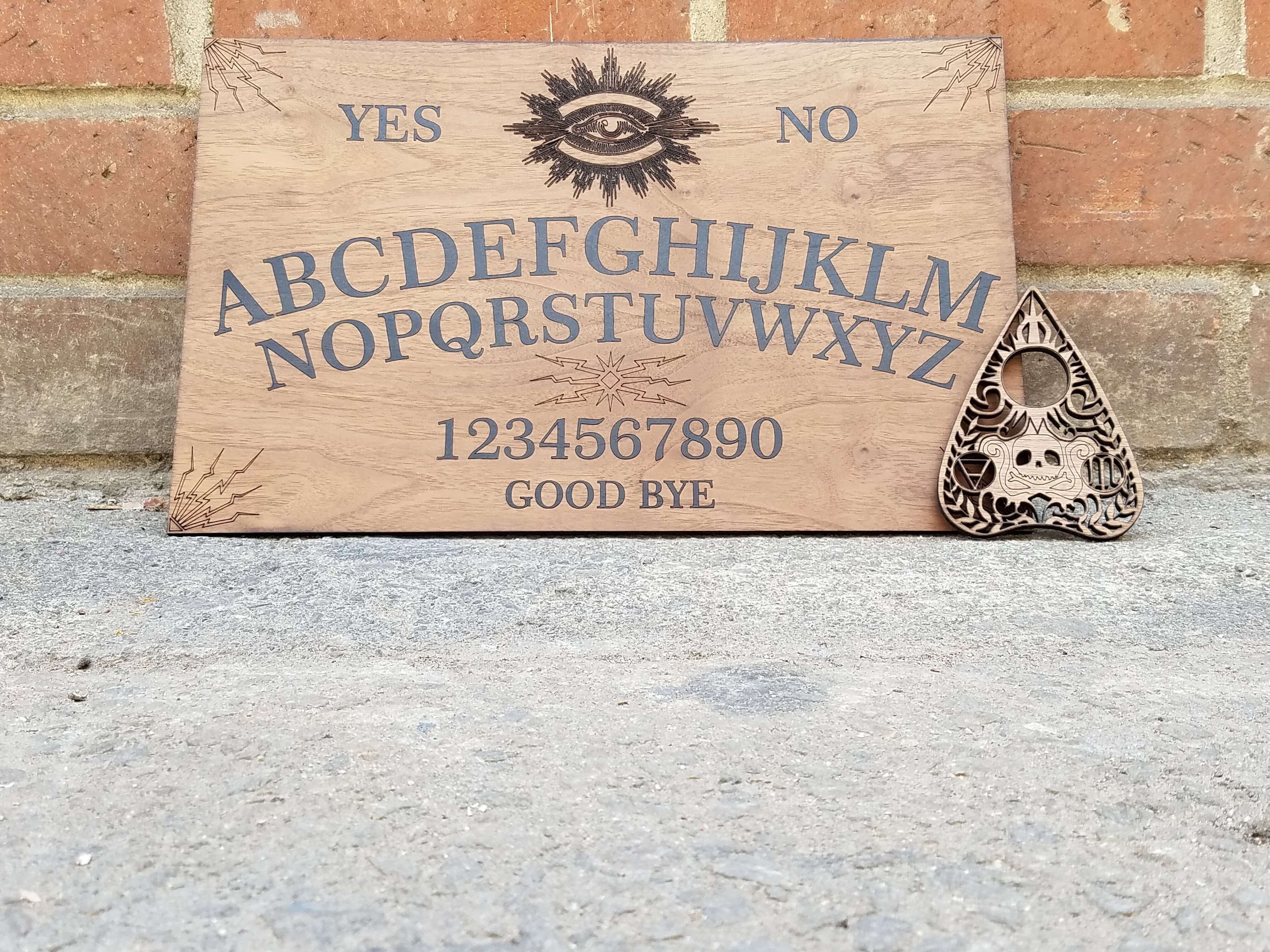

Laser Cutting (Our Specialty): Non-contact, highly repeatable, and fast to iterate. Yields polished edges, tight tolerances, tiny cutouts, and crisp engraving or score lines.

Cast vs. Extruded Acrylic

Both machine well, but they behave differently. Cast acrylic tends to engrave with a frosty white contrast and resists stress crazing; it’s ideal for optical clarity and crisp graphics. Extruded acrylic often cuts slightly faster and is budget friendly, but it can respond differently to solvents and heat. If you have a preference or brand requirement, you’re welcome to provide your own laser-safe material.

Design Tips for Better Results

Kerf & Fit: Account for a small kerf so press-fits and slots are dialed in.

Hole Sizes: For fasteners, leave clearance rather than exact nominal sizes.

Tabs & Slots: Keep tabs wide enough to avoid heat buildup and warping.

Heat-Forming: Add score lines where you plan to bend; test on scrap first.

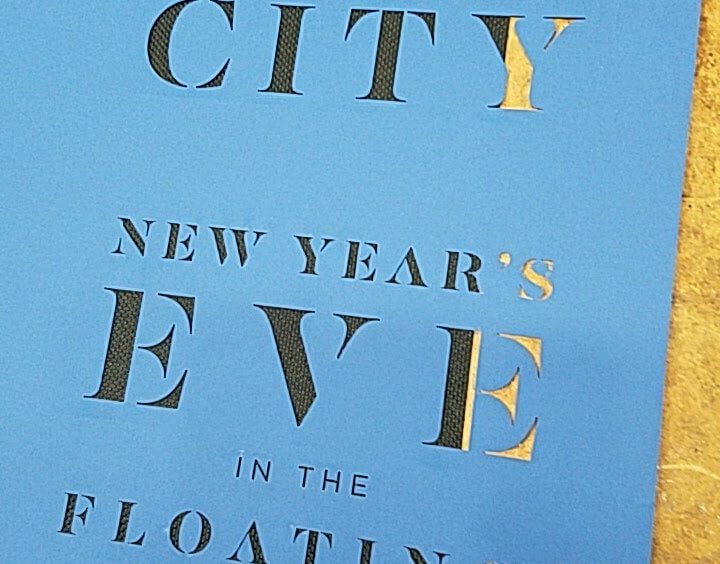

Engraving: Vector hairlines for score; filled shapes for surface engraving.

File Requirements (Vector Only)

To cut or engrave accurately, submit AI, DXF, or PDF vector files. We do not accept raster formats like JPEG or PNG. Organize operations by color or layers (e.g., red = cut, blue = score, black = engrave) and include material, thickness, and quantities. This speeds quoting and prevents avoidable revisions.

Why Use American Laser Cutter

Precision & Repeatability: Calibrated settings for acrylic thicknesses and colors.

Clean Edges: Laser-polished profiles reduce post-processing.

Small Features: Fine kerf preserves detail that saws and routers can’t reach.

Clear Communication: Practical manufacturability feedback before production.

Get a Quote

Send your vectors and project details through our form: https://www.americanlaserco.com/laser-cut-quote, or email americanlaserco@gmail.com. Please keep quotes to the form or email; phone is best for quick questions only. Our shop visits are by appointment only.

American Laser Cutter serves designers, engineers, makers, and brands across Los Angeles who want acrylic parts that look sharp, fit right, and assemble fast. If you’re ready to turn a drawing into dependable acrylic components, we’re ready to cut. Submit today to start your next acrylic build fast.

Contact Us

Hours by appointment only

Monday–Friday

10am–6pm

Phone

213-866-4738

americanlaserco@gmail.com

Location

1319 South Los Angeles ST, LA, CA 90015

American Laser Cutter is a professional laser cutting and engraving company based in Downtown Los Angeles. We offer precision cutting, scoring, and etching services for a wide range of materials, serving both businesses and individuals. Whether you need custom parts, prototypes, signage, or creative projects, our team provides fast, accurate results with expert attention to detail. We also offer DIY laser cutting rentals and repair services for CO₂ laser machines.

At American Laser Cutter, we work with a wide range of materials, including wood, acrylic, paper, cardboard, leather, rubber, and select plastics. We specialize in precise laser cutting, scoring, and engraving for custom parts, signage, stencils, packaging, architectural models, product displays, and creative projects. Whether you're a designer, engineer, artist, or entrepreneur, we can help you bring your ideas to life with clean, accurate results.