American Laser Cutter: Your Precision Cutting Partner in Los Angeles

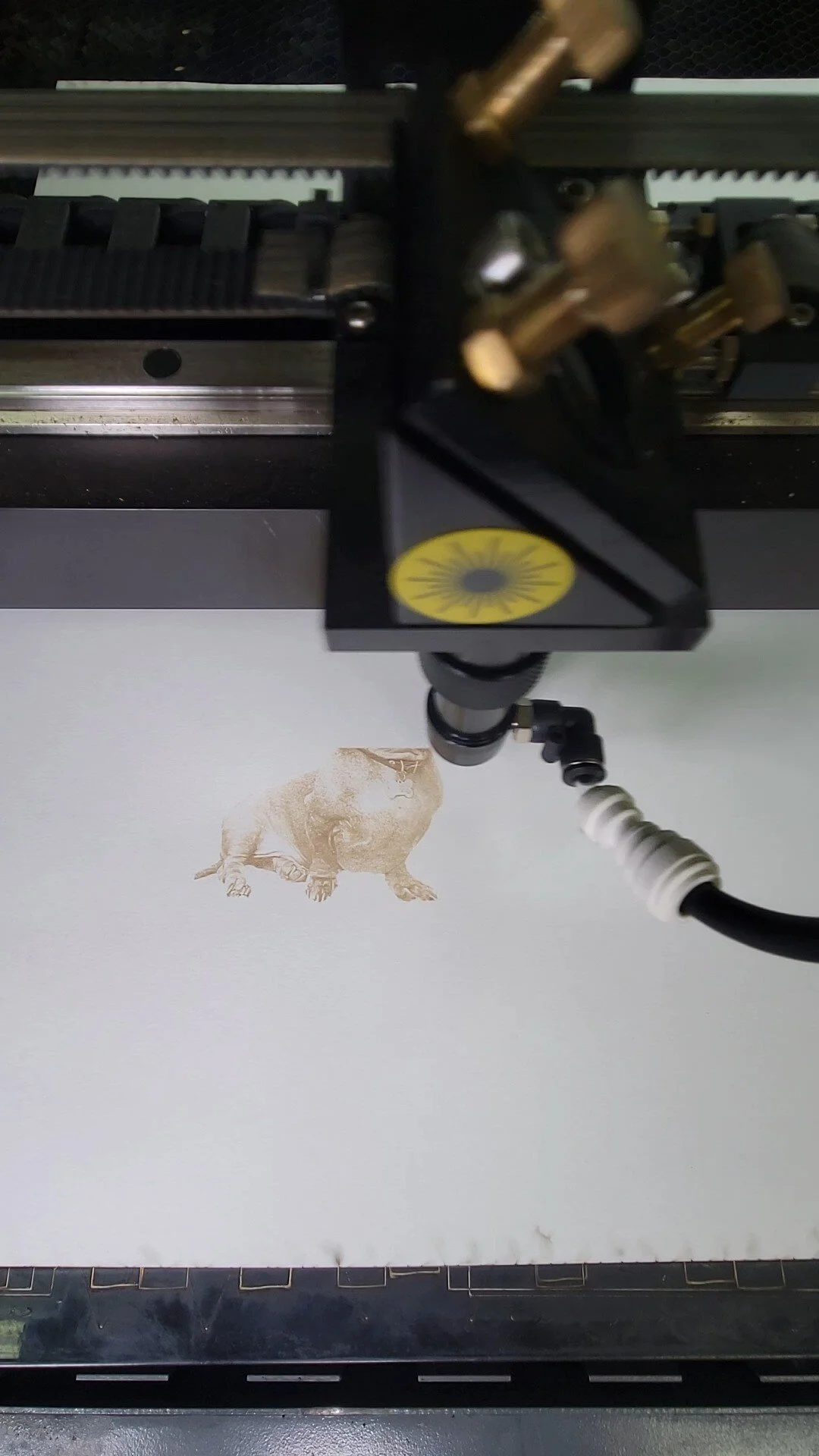

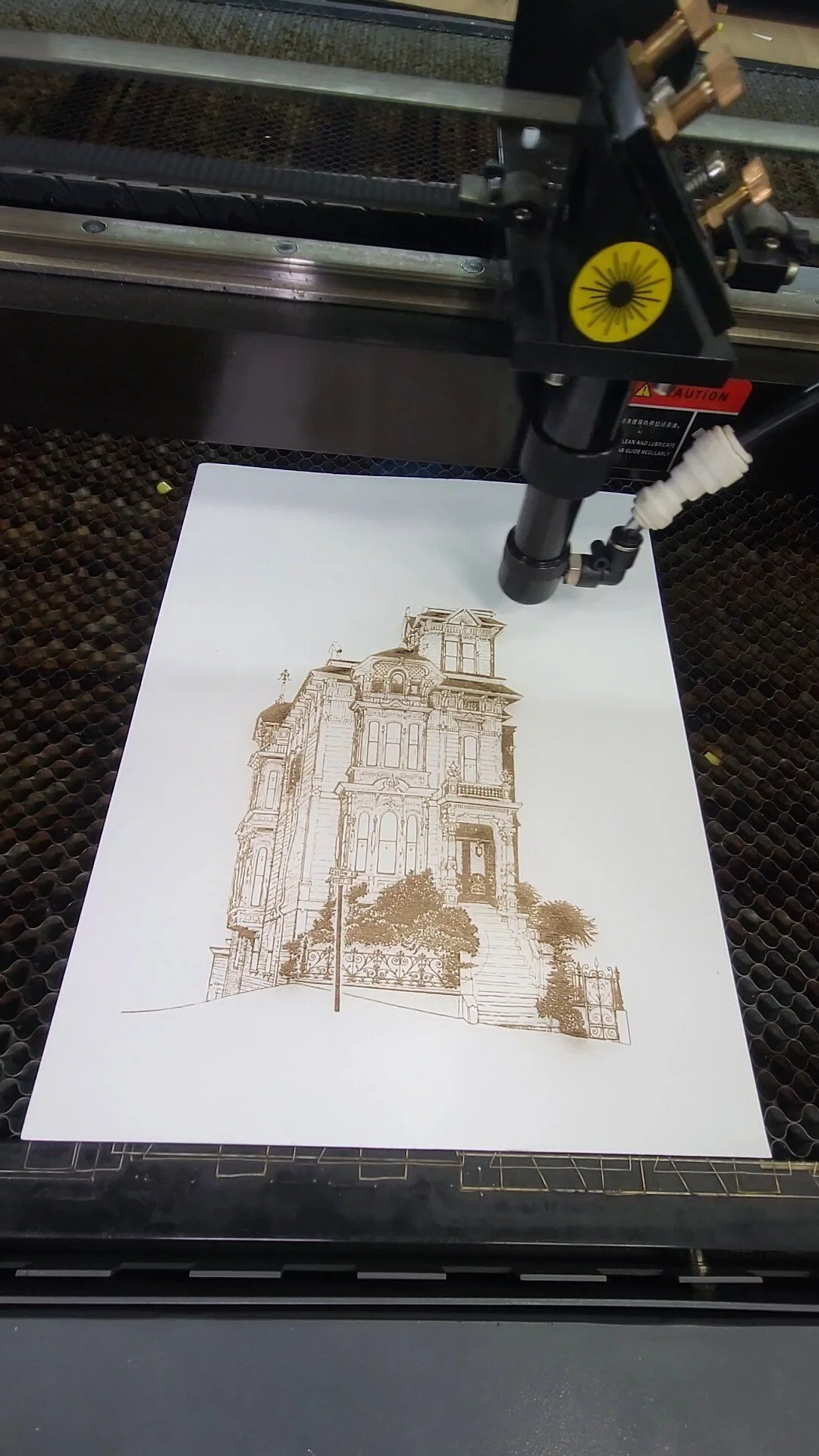

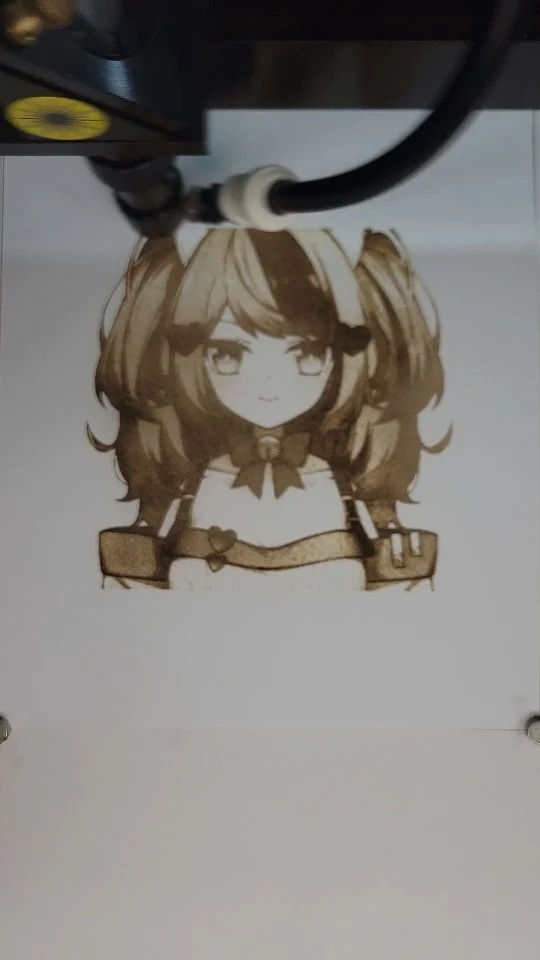

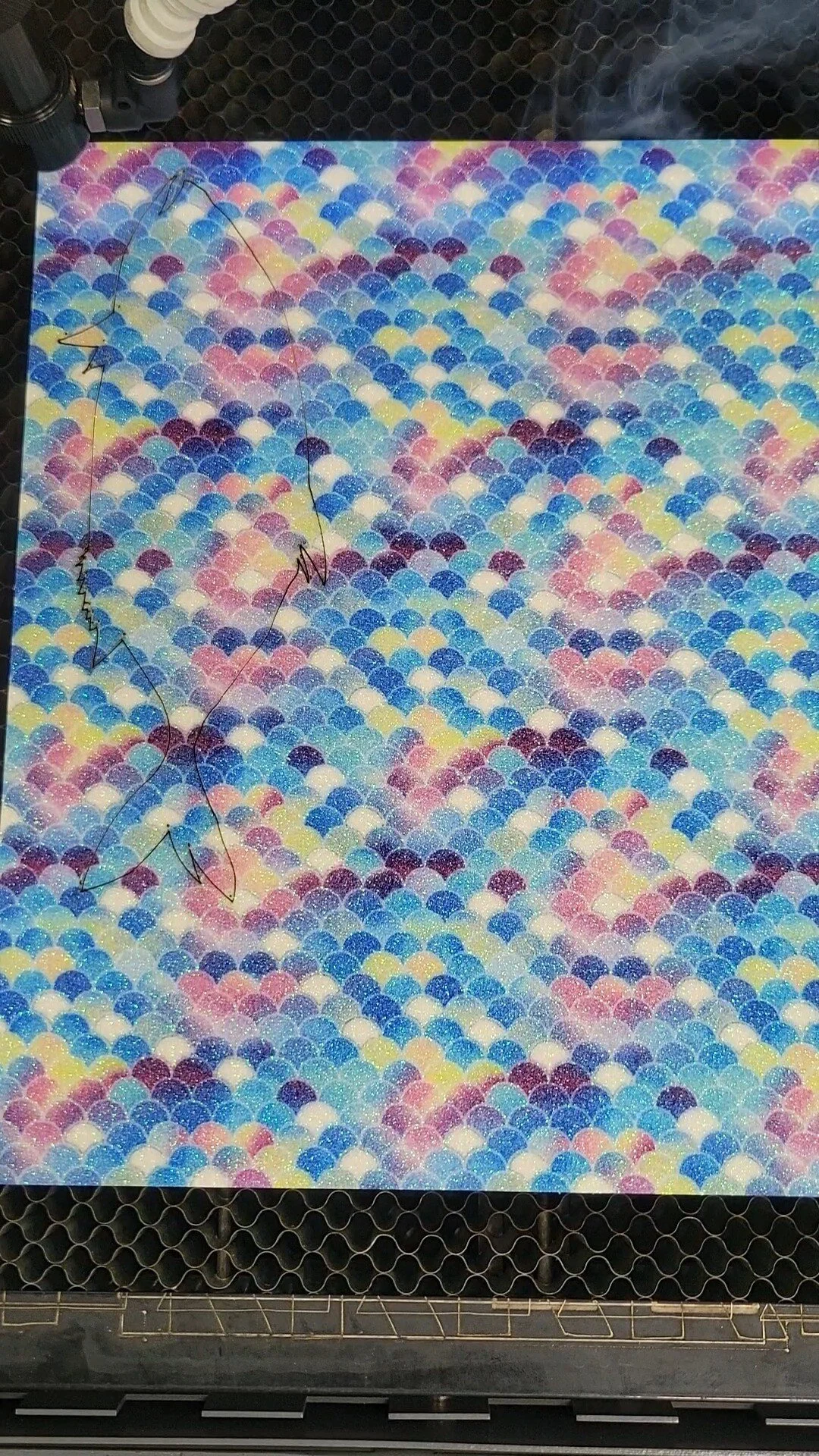

American Laser Cutter, based in Los Angeles, offers a comprehensive suite of laser cutting solutions tailored for both individuals and businesses. We distinguish ourselves through a unique blend of accessibility, expertise, and advanced technology. Our core offerings include DIY (Do-It-Yourself) laser cutting services, where clients can rent and operate industrial-grade CO2 laser cutters, including unique large-format machines (3'x4' and 4'x5') unparalleled for self-service in LA. Complementing this, we provide professional laser cutting, engraving, etching, and scoring services for those preferring a hands-off approach or requiring large-scale production, guaranteeing fast turnaround times. We specialize in a wide array of materials such as wood, acrylic (including 1/2 inch thick acrylic), fabric, leather, paper, cardboard, and foam, and even stock common plexiglass and plywood for client convenience. Beyond direct cutting, American Laser Cutter is a true laser hub, offering expert training, including an "Intro to LightBurn" course available remotely or on-site, to empower users with software mastery and material knowledge. We also provide laser cutter repair and maintenance services, leveraging over a decade of experience to support clients with our machines, ensuring consistent operation and offering valuable technical support during all DIY sessions.

My Laser Cutter Stopped Working: Who to Contact?

My Laser Cutter Stopped Working: Who to Contact?

A malfunctioning laser cutter can be a significant setback for any business or hobbyist. Knowing who to contact for assistance is crucial. Here's a breakdown of your options:

1. Manufacturer or Supplier:

Warranty Coverage: If your laser cutter is still under warranty, contact the manufacturer or supplier immediately. They might provide free repairs or replacements.

Technical Support: Even if your warranty has expired, they can offer troubleshooting advice or refer you to qualified technicians.

Manufacturer support issues: if you are having issues contacting your manufacturer or getting timely and quality service, we recommend reaching out to an independent Laser repair service like American laser cutter.

2. Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

Quick Turnaround: They often offer expedited services to minimize downtime.

3. Online Forums and Communities:

User Support: Online forums dedicated to laser cutters often have users who can share troubleshooting tips or recommend repair services.

DIY Solutions: Some issues might have simple solutions that can be found through online research.

Steps to Take Before Contacting Anyone:

Check Basic Issues: Ensure the laser cutter is properly plugged in, turned on, and that all cables are securely connected.

Review User Manual: Look for troubleshooting guides or error codes in the manual.

Inspect for Physical Damage: Check for any visible signs of damage to the machine or its components.

Remember: When contacting a repair service, provide as much detail as possible about the problem, including error messages, unusual noises, or specific symptoms. This information will help them diagnose the issue efficiently.

Top 10 Laser Cutting YouTube Channels to Follow

Top 10 Laser Cutting YouTube Channels to Follow

YouTube is a treasure trove of knowledge and inspiration for laser cutting enthusiasts. Here are ten channels that stand out for their informative content, creative projects, and engaging presentations:

Educational and Informative Channels

Make Something Inc: Offers a wealth of tutorials, tips, and tricks for laser cutting, from beginner to advanced levels.

The Wood Whisperer: While primarily focused on woodworking, this channel features excellent laser cutting segments with detailed explanations.

Laser Cut Studio: Provides in-depth tutorials and reviews of laser cutting machines and software.

The Stained Workshop: Offers a blend of woodworking and laser cutting projects, with clear instructions and stunning results.

Creative and Inspirational Channels

Jinsoaki: Known for intricate papercut art, this channel showcases the beauty and precision of laser cutting.

LaserDad: Offers a variety of projects, from home decor to functional items, with a focus on practical tips.

The Maker's Muse: Features a wide range of laser cut projects, inspiring creativity and experimentation.

Laser Cut Crafts: Offers a collection of creative and easy-to-follow laser cutting projects.

Business and Entrepreneurship

Make or Break Shop: Provides valuable insights into turning laser cutting into a profitable business.

Laser Business Top Seller: Shares tips and strategies for selling laser cut products online.

These channels offer a diverse range of content, from beginner tutorials to advanced techniques and business advice. By following these creators, you'll gain valuable knowledge, inspiration, and a deeper understanding of laser cutting.

DIY Laser Cutting: Your First Steps into the World of Laser Cutting

DIY Laser Cutting: Your First Steps into the World of Laser Cutting

Diving headfirst into owning a laser cutter might be daunting, but starting with DIY laser cutting services offers a fantastic way to explore the technology without the hefty upfront investment.

Why Start with DIY Laser Cutting?

Accessibility: It's a low-barrier entry point for those curious about laser cutting.

Experimentation: Try different materials and designs without the commitment of owning a machine.

Cost-Effective: Ideal for small projects or one-off designs.

Learning Curve: Understand the process and limitations before investing in your own equipment.

Finding a DIY Laser Cutting Service

Numerous online platforms and local makerspaces offer DIY laser cutting services. When selecting a service, consider the following:

Material Options: Ensure they offer the materials you need for your project.

File Formats: Check if they accept the design file formats you use (e.g., SVG, DXF).

Cut Quality: Review customer reviews or request samples to assess the quality of their cuts.

Pricing: Compare prices to find the best value for your money.

Turnaround Time: Consider how quickly you need your project completed.

Design Preparation

Once you've chosen a service, prepare your design:

Vector Graphics: Create your design using vector-based software like Adobe Illustrator, Inkscape, or CorelDraw.

File Format: Save your design as a compatible file format (SVG, DXF, etc.) as required by the service.

Kerf Consideration: Understand the kerf (material removed by the laser) and adjust your design accordingly.

1. What Is Laser Cutting Kerf? - KRRASS CNC Press Brake Online Shop

Test Cuts: Consider starting with smaller test cuts to refine your design and settings before committing to the full project.

Tips for Success

Clear Communication: Provide detailed instructions and specifications to the service provider.

Material Selection: Choose materials suitable for laser cutting and consider their thickness.

Design Optimization: Simplify your design for efficient cutting and reduce costs.

Safety Considerations: Familiarize yourself with laser cutting safety guidelines, even when using a service.

By following these steps and taking advantage of DIY laser cutting services, you can gain valuable experience and knowledge before deciding to invest in your own laser cutter.

LightBurn: The Powerhouse of Laser Cutting Software

LightBurn: The Powerhouse of Laser Cutting Software

LightBurn has become the go-to software for many laser cutter enthusiasts and professionals alike. Its robust feature set empowers users to create intricate designs, optimize laser settings, and streamline their workflow. Let's delve into some of its standout features.

1. Maximizing Your Laser Cutting Potential with Lightburn Software

Design and Editing

Vector Graphics: LightBurn excels at handling vector graphics, allowing for precise control over shapes, lines, and curves.

Image Tracing: Easily convert raster images (like photos) into editable vector graphics for laser cutting or engraving.

1. How to Import & Edit Designs Using Lightburn Software - OMTech Laser

Node Editing: Manipulate individual points on a path for detailed adjustments and customization.

Text Tools: Create text with various fonts, sizes, and styles, offering flexibility for text-based designs.

Laser Control

Power and Speed Control: Fine-tune laser parameters for optimal cutting or engraving results based on material and desired outcome.

Multiple Passes: Create intricate details and deeper cuts by setting up multiple passes with varying power and speed.

Offsetting: Easily create outlines or inner cuts by offsetting shapes.

Raster Engraving: Convert images into grayscale data for high-quality photo engraving.

1. Demystifying the Lightburn GRAYSCALE Image Mode - YouTube

Workflow Optimization

Job Management: Organize and manage multiple projects efficiently with the job manager.

Layer Management: Work with multiple layers of objects for complex designs and easy editing.

Camera Integration: Align materials accurately using the camera feature on compatible laser cutters.

Presets: Save and load custom settings for different materials and laser types to streamline workflow.

Additional Features

Variable Power: Gradually increase or decrease laser power during a cut for precise control.

Vector Hatching: Create fills with various patterns for artistic effects.

Import/Export: Work with a variety of file formats, including AI, SVG, DXF, and more.

1. Importing Files From Other Programs into Lightburn | Thunder Laser Canada

Plugin Ecosystem: Expand LightBurn's capabilities with third-party plugins.

LightBurn's comprehensive feature set makes it a valuable asset for laser cutter users of all skill levels. Whether you're a hobbyist or a professional, this software can help you achieve your creative vision.

1. Understanding LightBurn Software: Features and Pricing Guide - Monport Laser

LightBurn: The Ultimate Partner for Your Laser Cutter

LightBurn: The Ultimate Partner for Your Laser Cutter

LightBurn software has become an indispensable tool for many laser cutter users. It offers a range of features and benefits that significantly enhance the laser cutting experience.

1. Laser with Lightburn: The Best Laser Engraver Software!

2. Exploring the Key Features of LightBurn Engraving Software

Why Choose LightBurn?

Intuitive Interface: LightBurn boasts a user-friendly interface that makes it accessible to both beginners and experienced users. Its straightforward layout allows for efficient workflow and minimal learning curve.

Comprehensive Design Tools: With robust design capabilities, LightBurn empowers users to create intricate designs, edit vector graphics, and import various file formats (AI, SVG, DXF, etc.).

Precise Laser Control: The software offers granular control over laser parameters such as power, speed, and frequency, allowing for fine-tuning of cuts and engravings.

1. Exploring the Key Features of LightBurn Engraving Software

Image Processing: LightBurn excels in converting raster images into vector graphics, making it ideal for photo engraving and creating detailed patterns.

Camera Integration: Some laser cutters can be equipped with cameras, and LightBurn can utilize this feature to accurately position and align materials.

1. Maximizing Your Laser Cutting Potential with Lightburn Software

Job Management: Efficiently organize and manage multiple projects with LightBurn's job management system.

Compatibility: LightBurn supports a wide range of laser cutters, making it a versatile choice for different machines.

1. The Difference Between LightBurn and LaserGRBL - ACMER laser engraver

Community and Support: A thriving online community provides valuable resources, tutorials, and support for LightBurn users.

How LightBurn Enhances Your Laser Cutting Experience

By using LightBurn, you can:

Increase Productivity: Streamline your workflow and reduce setup time.

Improve Accuracy: Achieve precise cuts and engravings with advanced control options.

1. Integrating Your OMTech Laser with LightBurn: A Step-by-Step Guide - Monport Laser

Expand Creative Possibilities: Explore new design techniques and materials.

Save Time and Money: Optimize material usage and reduce errors.

In conclusion, LightBurn is a powerful and versatile software that can significantly enhance your laser cutting experience. Whether you're a hobbyist or a professional, investing in LightBurn can be a game-changer for your projects.

1. Maximizing Your Laser Cutting Potential with Lightburn Software

Forum coming soon

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)