Prototyping for Startups

Move from concept to testable parts with precise laser-cut panels and flat components. Our process delivers repeatable geometry and clean edges for tight mockups and pilot builds. Clients can provide their own laser-safe materials, or we can use standard stock. Files must be AI, DXF, or PDF.

What we produce:

Front panels, bezels, faceplates

Flat internal partitions and backers

Display elements and simple fixtures

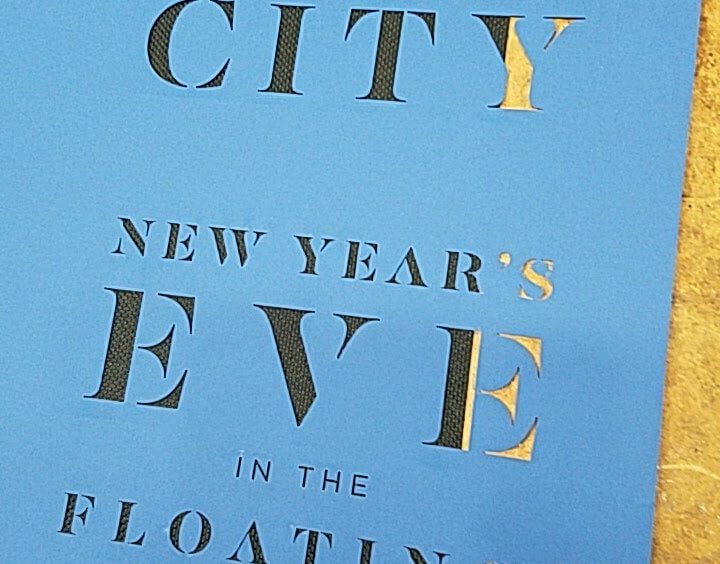

Branded overlays and engraved labels

Guidelines:

Provide vector layers for cut vs. engrave.

Convert all fonts to outlines.

Indicate hole sizes, slots, counterbores (as outlines), and overall dimensions.

Keep features within material-appropriate limits.

Why it helps:

Rapid iteration with consistent parts

Accurate repeatability across revisions

Clean integration of labeling and graphics

For version control, include revision identifiers in the file name or as small engraved marks if desired. We run the exact geometry you supply, keeping each iteration traceable and comparable.

Send AI/DXF/PDF via the quote form or email with quantities, dimensions, and material details. Our shop is in Downtown Los Angeles; visits are by appointment only. If bringing your own materials, confirm laser-safe status and list sheet size and thickness for accurate planning.

Use Case: Prototyping for Startups (Panels, Enclosures, Quick Iterations)

Overview

We help startups rapidly move from concept to functional prototype by laser cutting panels, enclosures, and precision components for early-stage hardware or product development. Our process eliminates long lead times and tooling costs, allowing teams to test, refine, and reassemble designs in days.

Scenario

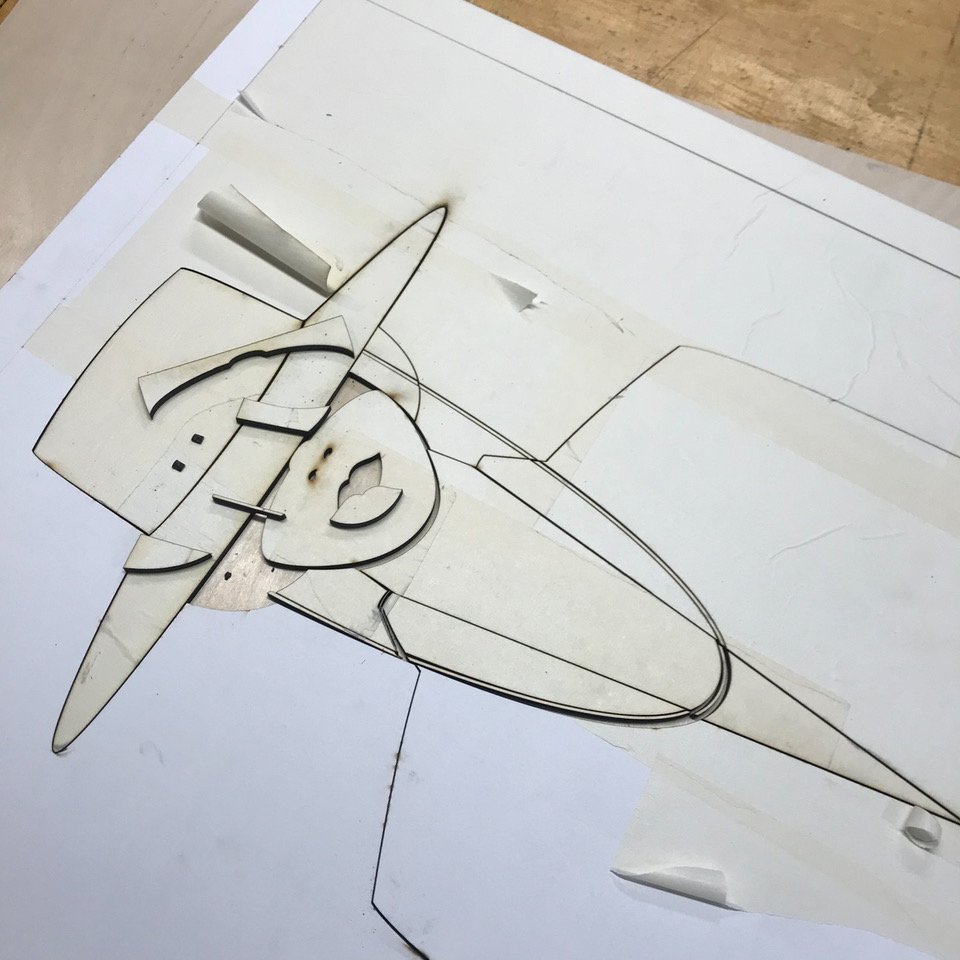

A hardware startup developing a new smart home controller needs a physical enclosure to test component fit and heat management. They provide flat layout files for front and rear panels, ventilation cutouts, and mounting slots.

We laser cut the prototypes from acrylic and plywood, producing clean, exact edges with tight tolerances. Multiple versions are made in a single session so the team can experiment with layout changes, button spacing, and logo placement. Within a few days, they’re testing real hardware inside a production-quality shell.

What Clients Receive

Precision-cut prototype components ready for assembly

Multiple iterations from one file batch

Consistent accuracy for repeatable testing

Material options for structure, transparency, or finish

Flat-packed parts for easy modification and shipping

Benefits

Reduces time from CAD to physical prototype

Allows fast testing of function, fit, and design

Supports incremental design refinement without retooling

Ideal for proof-of-concept, pitch demos, and pre-production validation

Call to Action

Accelerate your hardware development with fast, accurate laser-cut prototypes from American Laser Cutter.

Contact Us

Hours by appointment only

Monday–Friday

10am–6pm

Phone

213-866-4738

americanlaserco@gmail.com

Location

1319 South Los Angeles ST, LA, CA 90015

American Laser Cutter is a professional laser cutting and engraving company based in Downtown Los Angeles. We offer precision cutting, scoring, and etching services for a wide range of materials, serving both businesses and individuals. Whether you need custom parts, prototypes, signage, or creative projects, our team provides fast, accurate results with expert attention to detail. We also offer DIY laser cutting rentals and repair services for CO₂ laser machines.

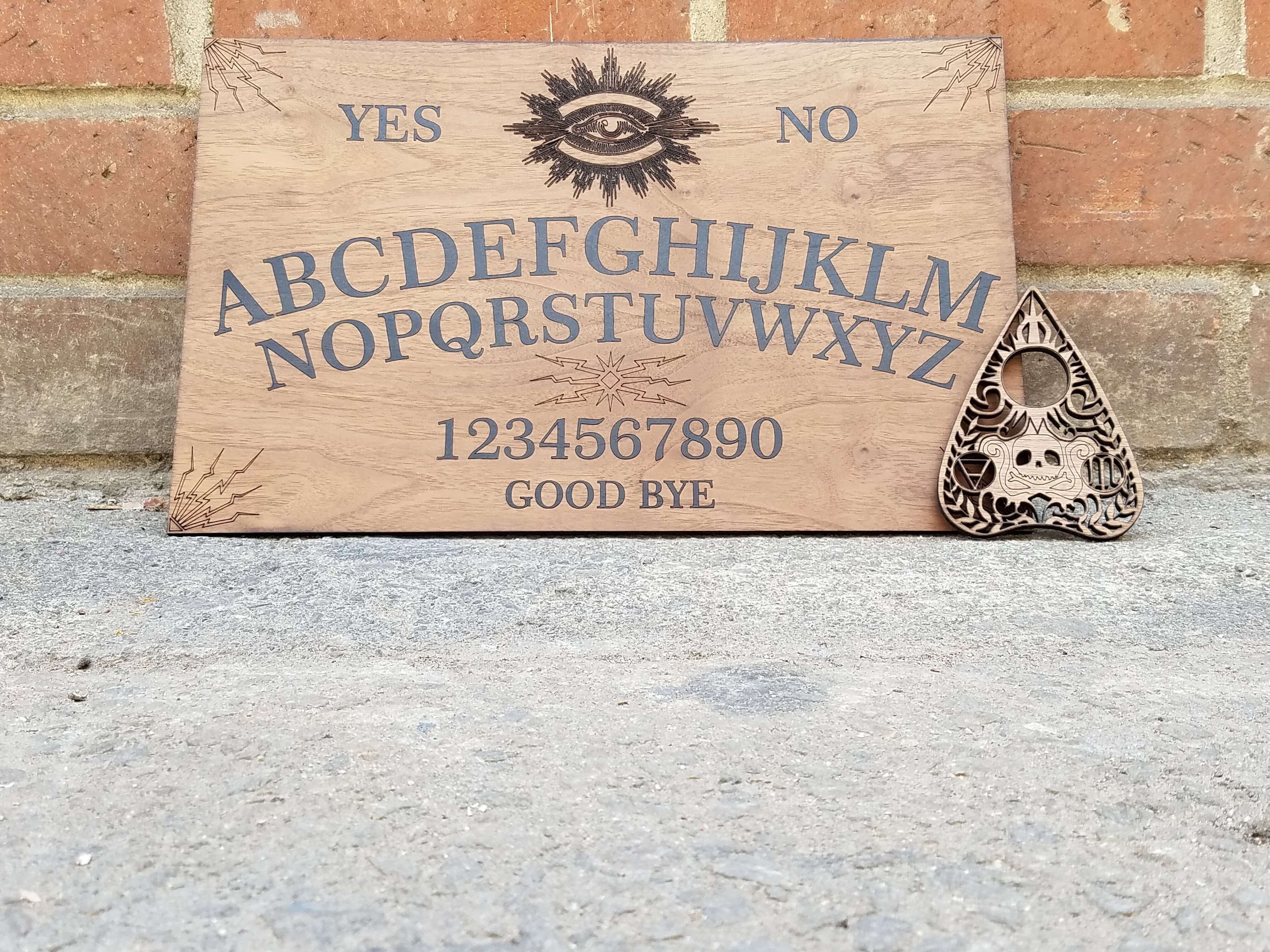

At American Laser Cutter, we work with a wide range of materials, including wood, acrylic, paper, cardboard, leather, rubber, and select plastics. We specialize in precise laser cutting, scoring, and engraving for custom parts, signage, stencils, packaging, architectural models, product displays, and creative projects. Whether you're a designer, engineer, artist, or entrepreneur, we can help you bring your ideas to life with clean, accurate results.