Laser 101: f.a.q and tips about Laser cutting

New to laser cutting? Start here. We explain the basics—how CO₂ lasers cut and engrave, which materials are safe, and how to set up your file. You’ll learn the difference between cutting and engraving, why vector files matter, and simple ways to avoid burn marks or rough edges. We also cover safety, ventilation, and tips for better results. Whether you plan to rent a laser or have us do the work, this quick guide will help you make confident choices and get cleaner parts.

FAQs

- Cutting vs. engraving—what’s the difference?

Cutting goes through the material; engraving marks the surface. - Which materials are safe to cut?

Common options include acrylic, wood, cardboard, some fabrics, and other laser-safe materials. Avoid PVC and unknown plastics. - Why won’t JPEG or PNG work for cutting?

They don’t contain paths. Laser cutters need vector files like AI, DXF, or PDF. - What software should I use?

Illustrator or LightBurn are common choices. Export clean vectors at the correct scale. - Any quick tips for cleaner results?

Use the right material, nest parts to save stock, keep optics clean, and choose sensible power/speed settings.

🎁 The Ultimate Guide to Crafting Custom Gifts with Laser Engraving

🎁 The Ultimate Guide to Crafting Custom Gifts with Laser Engraving

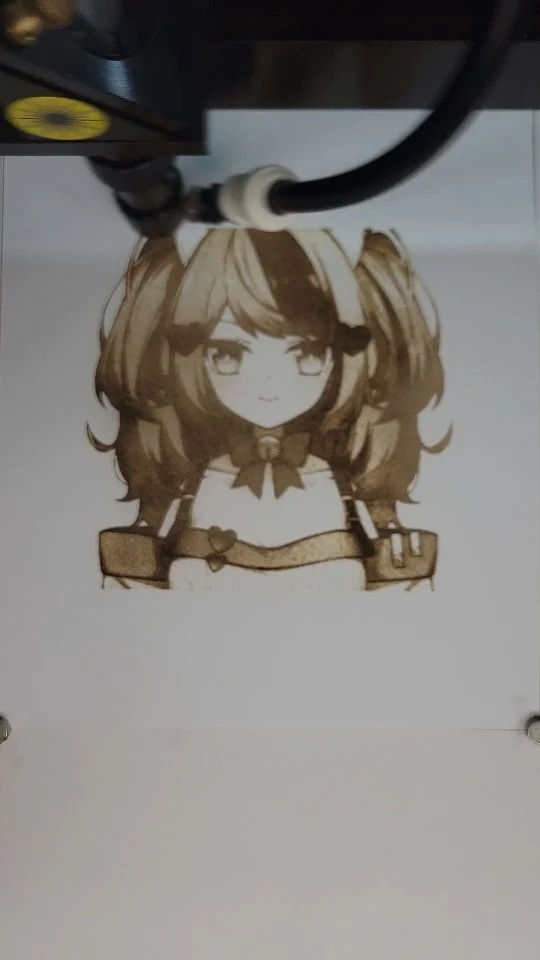

The power of the laser cutter lies in its ability to transform ordinary objects into deeply personal, one-of-a-kind gifts. Laser engraving adds a layer of personalization that goes beyond simple cutting, etching designs, names, and even handwriting onto a wide range of materials.

This article highlights some of the most popular and impactful custom gifts you can create with a laser.

Top 5 Customizable Gift Categories

Laser engraving is most impactful on items that combine utility with a touch of permanence.

1. Personalized Drinkware and Barware:

Ideas: Engrave names, logos, or witty quotes onto tumblers, mugs, or beer steins. You can apply custom designs to stainless steel items like a 40 oz. Polar Camel Travel Mug with Handle & Straw or a 6oz Custom Engraved Powder Coated Stainless Steel Flask (Source: Lazer Designs).

Materials: Powder-coated metals, glass, or ceramic.

2. Heirloom Kitchen Items:

Ideas: Cutting boards are a top seller, often engraved with a family name, a house design, or a Charcuterie Serving Board (Source: Totally Bamboo). You can also engrave family recipes or slate cheese/charcuterie trays (Source: Sam's Engraving and Gifts).

Materials: Hardwoods (Maple, Walnut, Bamboo) and Slate.

3. Professional and Executive Accessories:

Ideas: Turn office items into thoughtful corporate or personal gifts. Engrave initials onto leather portfolios with notepads (Source: Lazer Designs), journals (Source: Sam's Engraving and Gifts), or a custom Wood Handled Locking Blade Pocket Knife (Source: Weddingstar Inc.).

Materials: Leatherette (vegan leather), Faux Leather, Anodized Metal, and Wood.

4. Personal Keepsakes and Jewelry:

Ideas: Create unique accessories like a Personalized Wooden Jewelry Box (Source: Sam's Engraving and Gifts), custom laser engraved cufflink set (Source: Smart.DHgate), or a Custom Wood Magnet (Source: Steamer Lane Design).

Materials: Acrylic, Wood (Baltic birch, Plywood), and Faux Leather.

5. Custom Home Decor and Art:

Ideas: Design personalized art pieces such as a Hello World Birth Stat Announcement Wood Disc (Source: Claire and Bella), layered wood mandala art (Source: Monport Laser), or a custom Zip Code Christmas Ornament (Source: Geaux Magnolia).

Materials: Layered Plywood, Acrylic, and Granite.

Key Techniques for Customization

To make a gift truly custom, you need to understand the different processes a laser can perform:

Laser Engraving: This creates a cavity in the material, resulting in a visible and tactile texture, perfect for deep personalization on wood and acrylic (Source: Thunder Laser USA).

Laser Etching: This is a more delicate process that uses less heat to create a superficial mark, ideal for materials like plated metals or glass (Source: Gator Print Supply).

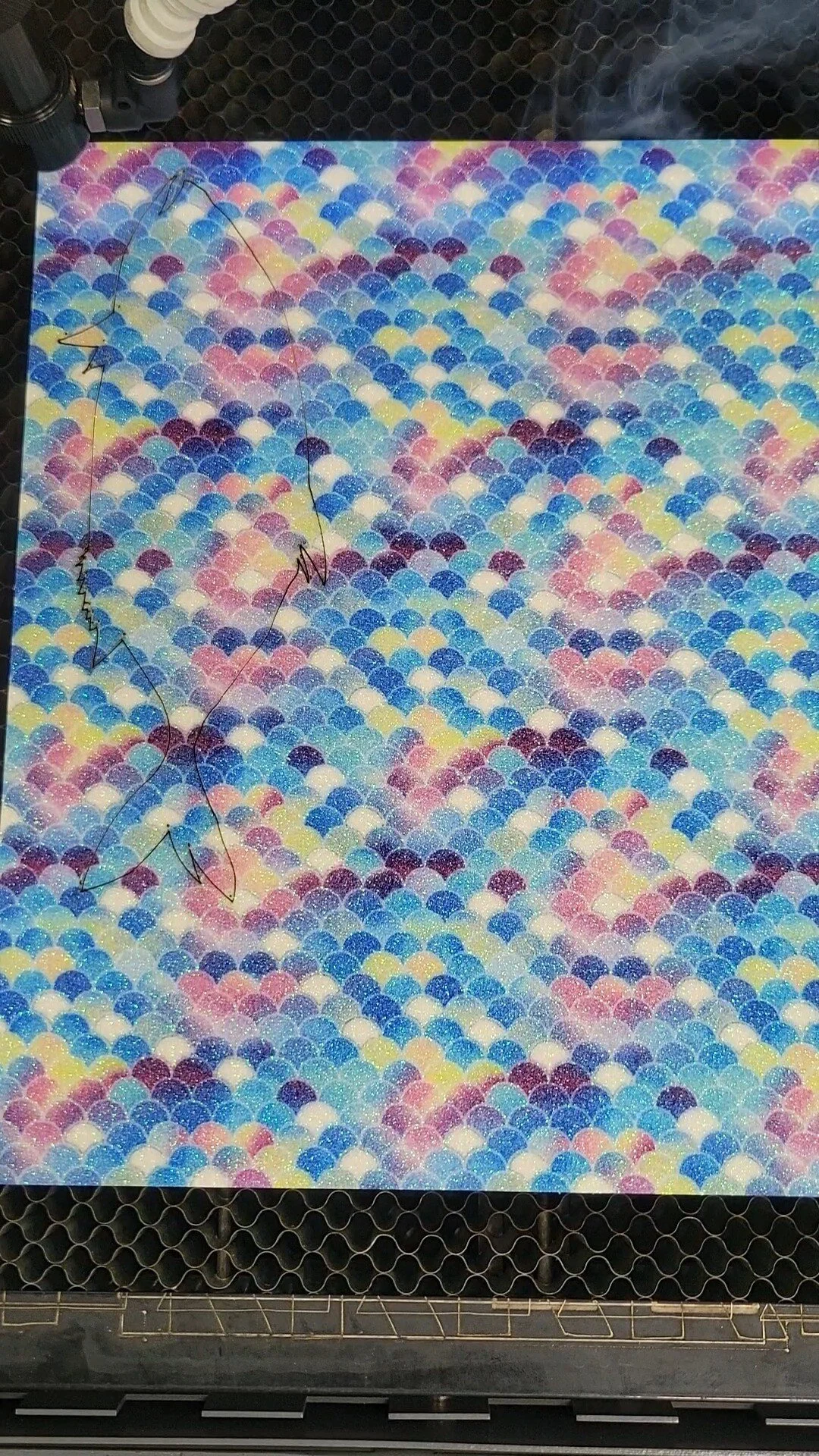

Vector Cutting: This is used to create unique shapes, such as cutting out a custom Laser Cut File, Snowman Christmas Svg (Source: Etsy) or an intricate layer-based puzzle out of wood or acrylic.

Safety in Laser Cutting: Best Practices

Here’s the next one in the seriLaser cutting is a powerful and versatile technology, but it comes with risks if not handled properly. High-powered beams, heat, fumes, and moving parts all require careful attention. Whether you’re operating an industrial machine or a desktop cutter, following safety best practices protects people, equipment, and materials.

Ventilation and Fume Control

One of the most important aspects of laser safety is proper ventilation. Cutting and engraving release smoke and fumes that can be harmful.

Install Exhaust Systems: Connect the machine to an exhaust fan or duct system that vents outside.

Use Air Filtration: In spaces where venting isn’t possible, use a filtration unit with HEPA and activated carbon filters.

Check Material Safety: Some materials, like PVC or ABS, release toxic gases and should never be cut.

Good airflow keeps both the operator and the equipment safe.

Fire Prevention

Laser cutters concentrate intense heat on small areas, making fire prevention a top priority.

Never Leave the Machine Unattended: Fires can start quickly.

Keep a Fire Extinguisher Nearby: A CO₂ or dry chemical extinguisher is recommended.

Monitor Material Choices: Flammable materials like paper, fabric, and thin wood require careful settings.

Use Air Assist: A steady stream of air reduces the chance of ignition.

Simple precautions minimize fire risks dramatically.

Personal Protective Equipment (PPE)

Operators should use appropriate protection when working around lasers.

Eye Protection: Industrial lasers require laser-rated safety glasses. Desktop CO₂ machines with proper enclosures usually don’t.

Respiratory Protection: If ventilation is inadequate, a respirator may be necessary.

Gloves: Useful when handling freshly cut materials with sharp edges.

The level of PPE depends on the machine and environment.

Machine Maintenance

Safe operation also depends on a well-maintained machine.

Clean Optics: Dirty lenses and mirrors can scatter the beam, increasing fire risk.

Check Alignment: Misaligned optics reduce efficiency and may cause overheating.

Inspect Ventilation Systems: Replace filters regularly.

Tighten Belts and Rails: Loose parts can cause inaccurate movement and potential hazards.

Routine checks extend machine life and keep cuts reliable.

Workspace Organization

A clutter-free workspace improves safety.

Clear Flammable Items: Keep paper, fabric, and solvents away from the cutter.

Organize Tools: Place wrenches, rulers, and spare parts in designated spots.

Provide Adequate Lighting: Ensure the operator can monitor the cutting area clearly.

Training and Procedures

Even the best equipment is unsafe without knowledgeable operators.

Training: New users should receive instruction before operating machines.

Standard Procedures: Establish checklists for startup, shutdown, and emergency steps.

Emergency Plan: Make sure all users know how to shut down power and ventilation quickly.

Electrical and Mechanical Safety

Laser cutters are electronic machines with moving parts.

Grounding: Ensure the machine is properly grounded.

Cabling: Keep cords intact and away from heat.

Interlocks: Many machines include safety interlocks; never bypass them.

Questions & Answers

Q1: Why is ventilation important in laser cutting?

A: It removes smoke and harmful fumes, protecting both users and the machine.

Q2: What’s the biggest fire risk with lasers?

A: Flammable materials like paper or fabric can ignite if left unattended or cut at incorrect settings.

Q3: Do I always need laser safety glasses?

A: For enclosed CO₂ machines, no. For open or industrial lasers, yes — rated glasses are essential.

Q4: How often should I clean the laser optics?

A: Regularly. Dirty optics scatter heat, which increases fire risk and reduces cutting quality.

Q5: What materials are unsafe to cut?

A: PVC, ABS, fiberglass, and polycarbonate release hazardous fumes and should be avoided.

🛠️ The Essential Guide to Sourcing Laser Cutter Replacement Parts

🛠️ The Essential Guide to Sourcing Laser Cutter Replacement Parts

Keeping your laser cutter running smoothly is crucial for any maker, hobbyist, or industrial fabricator. Just like any precision machine, laser cutters require regular maintenance and, eventually, replacement parts. The good news is that a robust ecosystem of suppliers is available to minimize your downtime.

Here is an article detailing where to find the essential replacement components for your laser cutting machine.

Three Primary Sources for Parts

The best place to buy a replacement part depends on your machine's brand, the component's complexity, and your budget.

1. The Original Equipment Manufacturer (OEM)

Owners of major brands like xTool, FLUX, or Full Spectrum Laser (FSL) Source: Ultimate 3D Printing Store can buy parts directly from the manufacturer. This is the only way to guarantee an exact fit and maintain your warranty. Specialized components, like a proprietary Laser Tube for xTool P2 Source: Ultimate 3D Printing Store or specific control hardware, are typically best sourced here.

2. Dedicated Third-Party Parts Suppliers

These suppliers are often the most cost-effective option for common consumables and compatible parts. Companies like OMTech Source: OMTech and Cloudray Laser Source: Cloudray Laser specialize in a wide inventory of components compatible across many generic machine brands.

3. Industrial and Alternative Parts Specialists

For those running high-end, industrial-grade equipment from brands like Amada or Precitec Source: Alternative Parts Inc., specialized suppliers exist. These companies, such as Alternative Parts Inc. Source: Alternative Parts Inc., manufacture OEM equivalent replacements, which can offer significant cost savings Source: Alternative Parts Inc. without sacrificing quality.

Key Components You Will Need to Replace

The type of laser you own dictates which parts are considered high-wear consumables.

Laser TypeCommon Replacement/Consumable PartsCO2 LaserLaser Tubes are the most common component requiring replacement, as they are temporary parts that eventually burn out, much like light bulbs Source: EFR 100W Tube on eBay. Other key parts include ZnSe Laser Focusing Lenses Source: Boss Laser and Molybdenum Laser Engraving Mirrors Source: OMTech.Fiber LaserThese machines require replacements for specialized optics, including Fiber Laser Nozzles Source: American Photonics and Ceramic Nozzle Holders Source: American Photonics.Mechanical/GeneralThese include parts like Honeycomb Working Tables Source: Cloudray Laser, motion control hardware, and accessories like Air Assist components Source: Boss Laser and Water Flow Sensors Source: Boss Laser.

Pro-Tips for Buying Replacement Parts

Know Your Specifications: Always check your machine's manual for the exact specifications of the part you need. For laser tubes, this includes the rated power (e.g., 100W) and the physical length and diameter (e.g., 1450 mm long and 80 mm diameter) Source: EFR 100W Tube on eBay.

Optics Dimensions: For lenses, confirm the diameter ($D$) and focal length ($FL$) to ensure peak cutting performance Source: Boss Laser.

Don't Forget Safety: Components like Laser Safety Glasses Source: American Photonics should be replaced if damaged or if you switch to a laser with a different wavelength.

🎄 Precision & Personality: The Magic of Laser-Cut Christmas Decorations

🎄 Precision & Personality: The Magic of Laser-Cut Christmas Decorations

The holiday season is a time for warmth, sparkle, and, increasingly, personalization. While mass-produced decorations fill store shelves, a growing trend is allowing makers and enthusiasts to craft intricate, custom holiday items right from their own workshops: laser cutting Christmas decorations. With unparalleled precision and a wide array of material options, the laser cutter is quickly becoming the ultimate tool for DIY holiday cheer.

Endless Design Possibilities

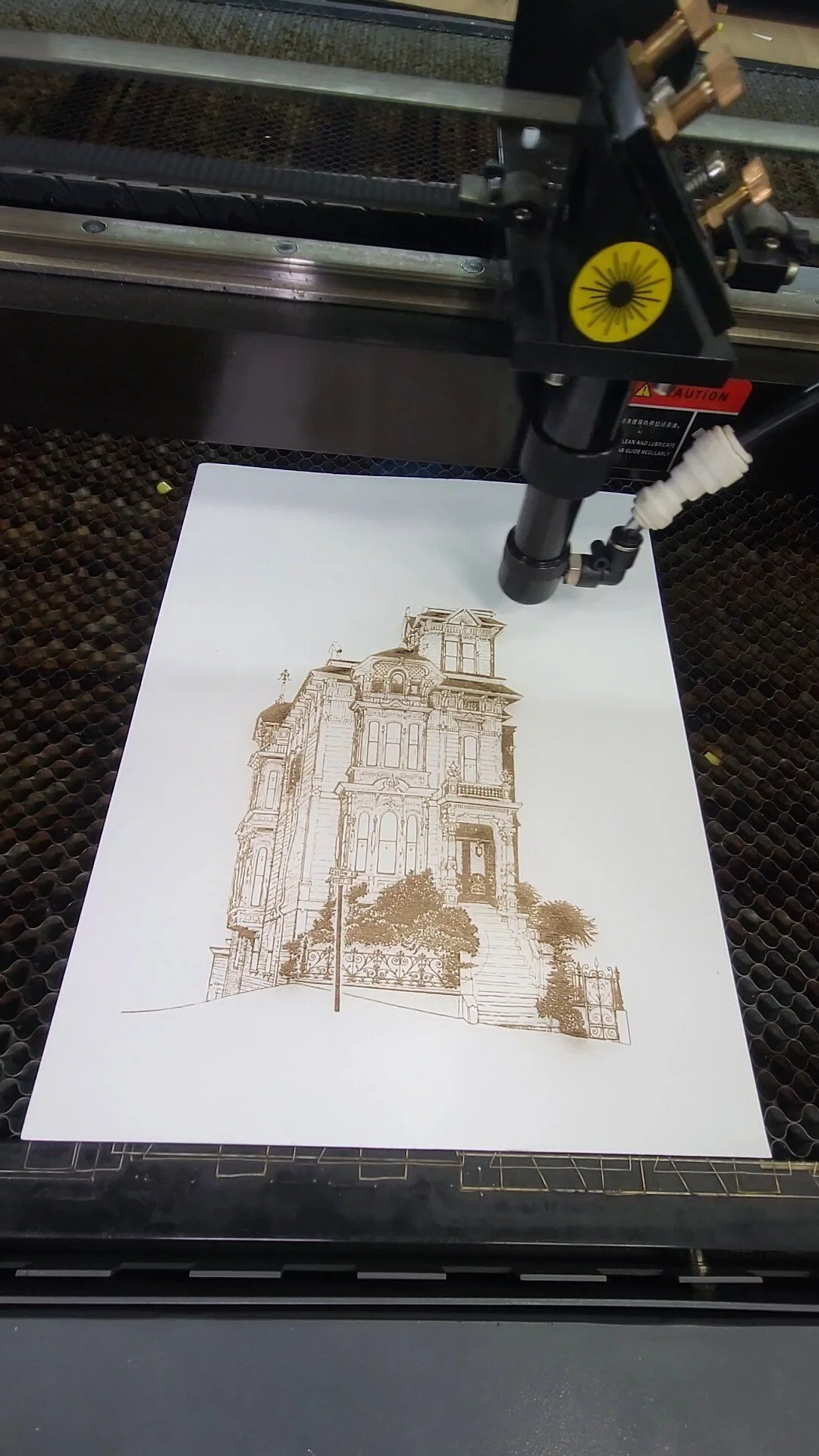

A laser cutter's ability to create ultra-fine, precise cuts and detailed engravings unlocks a world of design that is nearly impossible to achieve by hand. This technology transforms simple materials into bespoke, elegant, or whimsical holiday pieces.1

Intricate Ornaments: Forget bulky store-bought baubles. Laser cutters excel at delicate work, turning out ornate snowflake designs and layered 3D ornaments with mesmerizing detail.2 Ideas include layered Christmas baubles that combine elements for depth or classic shapes like stars, bells, and reindeer (Source: 10 Laser Cut Christmas Ornaments Ideas in 2025 - LaserPecker).

Personalized Keepsakes: The most popular laser-cut items are those with a personal touch. Engrave family names, birth years, or special holiday messages onto wooden stars with engraved messages to create treasured keepsakes. You can even design photo frame ornaments to display cherished memories on the tree (Source: 10 Laser-Cut Christmas Ornaments to Make with Your Kids - BoredMom).

Dimensional Decor: Go beyond flat hangings with larger projects. Laser cutters are perfect for constructing 3D gingerbread houses, decorative Christmas tree paper sculptures, or even functional items like a tree-shaped advent calendar with small compartments for treats (Source: DIY Laser-Cut Christmas Decorations: Creative Ideas for a Festive Holiday - toocaa).

Popular Materials to Cut

The versatility of the laser cutter allows for experimentation with various materials, each offering a unique aesthetic:

Wood (Plywood/Basswood): The classic choice for a rustic, handmade look.3 Plywood is easy to paint, stain, or glitter, while basswood sheets offer a fine grain for detailed engravings (Source: Create Custom Laser Cut Christmas Ornaments With Wood - Tea and Forget-me-nots).

Acrylic: Provides a modern, glossy finish.4 Clear acrylic can be used to create designs that catch the light, while colored or TroGlass Glitter acrylic can be cut for vibrant, festive accents (Source: 5 Things you can make with your laser cutter for the Christmas shopping season).

Cardboard/Paper: Ideal for delicate, budget-friendly pieces. Paper sculpture designs allow for complex layering that can add an elegant touch to mantels or tabletops (Source: 10 Laser Cut Christmas Ornaments Ideas in 2025 - LaserPecker).

Leather (LaserLeather): For a premium feel, LaserLeather (a vegan-friendly material) can be engraved and cut into personalized gift tags or accents for stockings (Source: 5 Things you can make with your laser cutter for the Christmas shopping season).

Tips for Crafting Success

Whether you're a beginner or a seasoned pro, a few steps can elevate your holiday crafting:

Start with Files: Don't reinvent the wheel. Many digital marketplaces offer laser cut files (often in SVG or DXF formats) specifically for Christmas ornaments, ranging from simple shapes to complex, multi-layered designs (Source: Laser Cut Christmas Ornaments - Etsy).

Design for Stability: For ornaments that connect to a ring or have internal cutouts, ensure the design overlaps enough with the outer frame to maintain stability once cut (Source: Create Custom Laser Cut Christmas Ornaments With Wood - Tea and Forget-me-nots).

Post-Processing is Key: The finishing touches make the piece. Use light sanding to remove burn marks, or get creative with paint, glitter, or wood oil for a custom look (Source: How to Laser Cut Christmas Ornaments with Laser Engravers - OMTech Laser).

Laser cutting allows you to transform your holiday decorating from a shopping trip into a creative, rewarding project.5 The resulting decorations—each one unique and often personalized—are not just ornaments; they are small, cherished memories of the season.

How to Prepare Files for Laser Cutting (and Avoid Rejections)

How to Prepare Files for Laser Cutting (and Avoid Rejections)

The Key to a Smooth Cutting Process

Submitting a file for laser cutting seems simple—until it gets rejected or produces unexpected results. The truth is that laser cutters require precision-ready vector files, not raster or photo-based images. A few small setup mistakes can cause wasted material, off-measure cuts, or even halted production.

Knowing how to properly prepare your file saves time, cost, and frustration—and ensures your project cuts perfectly the first time.

Use the Right File Type

The most important step is submitting a vector file, not a raster image. Accepted formats are:

AI (Adobe Illustrator)

DXF (AutoCAD)

PDF (vector-exported only)

Raster formats like JPEG, PNG, or TIFF can’t be used for cutting because they’re made of pixels, not paths. Even if the image looks sharp on-screen, a laser cutter can’t follow it as a defined path.

Keep Your Design Clean and Organized

Convert all text to outlines

Fonts must be outlined so the cutter reads them as shapes, not editable text.Use consistent line colors and weights

Typically, red for cuts and blue for engraves. Avoid extra layers or unneeded colors.Remove duplicates and hidden geometry

Overlapping lines or hidden objects can cause double cuts and material damage.Check scale and dimensions

Always design at 1:1 scale (actual size) and verify units—preferably in inches or millimeters.Ensure closed paths

Open vector paths cause incomplete cuts. Every shape should form a closed loop.

Keep File Complexity Reasonable

Too many small nodes or micro details can slow processing time and overheat materials. Simplify complex curves and eliminate unnecessary anchor points before exporting.

If you’re combining engraving and cutting in one file, make sure:

Engraving areas are separate from cut lines.

Engraving power and speed settings are balanced for the chosen material.

Avoid Common Mistakes

Submitting a photo or logo saved as a PDF (still raster inside)

Forgetting to outline text

Misaligned layers or inconsistent stroke colors

Artwork with embedded images instead of paths

Overlapping duplicate lines on shared edges

How American Laser Cutter Helps

Our team reviews every submitted file for compatibility before production. If there’s an issue, we’ll notify you immediately and guide you through the corrections—ensuring your design meets cutting requirements without delay.

We cut directly from AI, DXF, and vector PDF files, and we can handle both customer-supplied materials or in-house stock. Every project runs on professional CO₂ laser systems calibrated for accuracy and repeatability.

Conclusion

Proper file preparation is the foundation of a successful laser cutting project. A clean, organized vector file means faster turnaround, lower cost, and perfect precision.

If you want your design cut right the first time, American Laser Cutter can review, prepare, and cut your files—on-site in Los Angeles or remotely anywhere in the U.S.

Send your file to americanlaserco@gmail.com or visit americanlaserco.com to get started.

Common Problems in Laser Cutting (and Solutions)

Laser cutting is a precise and reliable process, but like any technology, it has challenges. Whether you’re a business running production or a hobbyist working on personal projects, understanding common problems — and their solutions — can save time, material, and frustration.

Burn Marks and Charring

Problem: When cutting wood or other organic materials, the edges sometimes burn, leaving dark marks.

Causes:

Too much laser power.

Slow cutting speed.

Inadequate air assist.

Solutions:

Increase cutting speed or reduce power.

Use masking tape on the surface to reduce scorch marks.

Ensure proper air assist to blow away smoke and heat.

Melting and Warping Plastics

Problem: Plastics such as acrylic may melt or warp during cutting.

Causes:

Excessive heat buildup.

Low-quality or extruded acrylic.

Solutions:

Use cast acrylic for cleaner cuts.

Optimize power and speed settings.

Use nitrogen or air assist to cool the cut area.

Poor Edge Quality

Problem: Edges may be rough, jagged, or inconsistent.

Causes:

Incorrect focus of the laser beam.

Dirty optics or lenses.

Wrong gas type or pressure.

Solutions:

Refocus the laser before cutting.

Clean mirrors and lenses regularly.

Adjust gas type — nitrogen produces smoother edges on metals.

Incomplete Cuts

Problem: The laser fails to cut all the way through the material.

Causes:

Material too thick for the machine.

Power too low or speed too fast.

Focus out of alignment.

Solutions:

Check the material thickness limits of your machine.

Reduce speed or increase power.

Realign optics and check beam focus.

Warped Material Sheets

Problem: Thin materials like plywood or cardboard may warp under the laser, leading to uneven cuts.

Causes:

Heat buildup.

Material not properly secured.

Solutions:

Use hold-down pins or weights.

Reduce power and increase cutting speed.

Cut multiple lighter passes instead of one heavy pass.

Excessive Kerf Width

Problem: The cut removes more material than expected, affecting accuracy.

Causes:

Beam focus too wide.

Incorrect settings for material type.

Solutions:

Fine-tune the focus.

Adjust speed and power to minimize burning.

Compensate for kerf in design software.

Unsafe Materials

Problem: Some users accidentally attempt to cut materials like PVC, ABS, or fiberglass.

Causes:

Lack of awareness of material hazards.

Solutions:

Always verify material safety before cutting.

Keep a reference list of safe and unsafe materials near the machine.

Alignment Issues

Problem: The laser doesn’t follow the intended path accurately.

Causes:

Loose belts or mechanical parts.

Calibration drift.

Solutions:

Tighten belts and check machine mechanics.

Perform routine calibration and maintenance.

Questions & Answers

Q1: Why does wood burn when laser cut?

A: Too much heat is applied. Adjusting speed, power, and air assist reduces charring.

Q2: How can I stop acrylic from melting?

A: Use cast acrylic, optimize settings, and use air or nitrogen assist to cool the cut.

Q3: What should I do if my laser doesn’t cut through the material?

A: Check thickness limits, adjust speed/power, and ensure proper focus.

Q4: Why do edges look rough or jagged?

A: The beam may be out of focus, optics may be dirty, or gas settings may be incorrect.

Q5: Which materials should never be cut with a laser?

A: PVC, ABS, polycarbonate, and fiberglass release harmful fumes or damage the machine.

The Hidden Danger of Inexperienced Laser Technicians

The Hidden Danger of Inexperienced Laser Technicians

In the world of laser repair, not all technicians are created equal. Over the years, we’ve been called out repeatedly to fix situations caused by others—sometimes well-meaning but inexperienced, other times careless or overconfident. These experiences have taught us that choosing the wrong technician can cost far more than money—it can cost the functionality of your machine and weeks, even months, of downtime.

Take one case we encountered: a customer had called a local repair service after their laser began misfiring intermittently. The technician followed a standard script, replacing a few components and performing quick adjustments, but the problem persisted. When we arrived, it became clear that the technician had misdiagnosed a critical power supply issue. The result? A $3,000 repair bill for parts and labor, and a machine that still wouldn’t cut properly. The frustration was palpable—weeks of lost production and wasted resources, all because someone who wasn’t prepared for complex on-site repair had attempted work beyond their capabilities.

Another example involved a recommendation that should never have been made. A technician suggested adjusting an internal assembly in a way that seemed minor but was incompatible with the machine’s design. Following that advice caused severe, permanent damage. What had started as a small issue escalated into a total system failure, leaving the customer with a machine that was essentially unusable. The lesson here is stark: even well-intentioned technicians can do extreme damage if they lack practical experience.

These stories aren’t meant to alarm, but to illustrate a critical truth: scripted support and inexperienced techs cannot substitute for hands-on knowledge. Manuals, flowcharts, and checklists only go so far; they cannot replicate the intuition and understanding that comes from repairing hundreds of machines firsthand.

At American Laser Cutter, our team brings over ten years of direct, on-site experience across hundreds of brands and thousands of individual lasers. We’ve seen nearly every failure scenario and know which fixes are safe, which adjustments are critical, and which shortcuts will create more problems than they solve. Whether troubleshooting remotely or repairing on-site, we rely on real-world knowledge—not a script—to deliver accurate, lasting solutions.

For anyone operating a laser, the takeaway is simple: carefully vet your technicians. Ask about their hands-on experience, the types of machines they’ve repaired, and whether they have actually handled repairs in person. The difference between a capable technician and an inexperienced one isn’t just skill—it’s the difference between a machine that runs reliably and one that ends up as a cautionary tale.

How Laser Cutting is Inspiring Artists in 2025

How Laser Cutting is Inspiring Artists in 2025

Laser cutting is often thought of as an industrial tool, but in recent years, it has become a creative medium for artists. Painters, sculptors, illustrators, and designers are using lasers not only to cut materials but to push the boundaries of what art can look like. In 2025, the intersection of technology and creativity has never been more exciting.

Precision as a Creative Tool

Artists traditionally rely on hand tools, brushes, or chisels. Laser cutters bring a new dimension of precision.

Intricate Details: Patterns that would take days by hand are done in minutes.

Consistency: Repeated elements match perfectly, supporting series and installations.

Freedom of Design: Digital files allow experimentation with shapes impossible to cut manually.

Expanding the Range of Materials

Laser cutters let artists explore unconventional surfaces.

Wood Panels: Engraved textures for mixed-media paintings.

Acrylic Sheets: Transparent layers etched with imagery for sculptures.

Paper and Cardstock: Cutouts for shadow art and installations.

Leather: Customized engravings for wearable art.

This material diversity broadens the definition of modern art.

Large-Scale Installations

Some artists use industrial-scale lasers to create pieces for galleries or public spaces.

Metal Sculptures: Fiber lasers cut steel and aluminum with precision.

Architectural Elements: Decorative panels serve as both art and structure.

Light and Shadow Art: Laser-cut screens create shifting patterns when illuminated.

The result is immersive environments that merge design and engineering.

Personalization and Storytelling

Artists also use laser cutting for personal narratives.

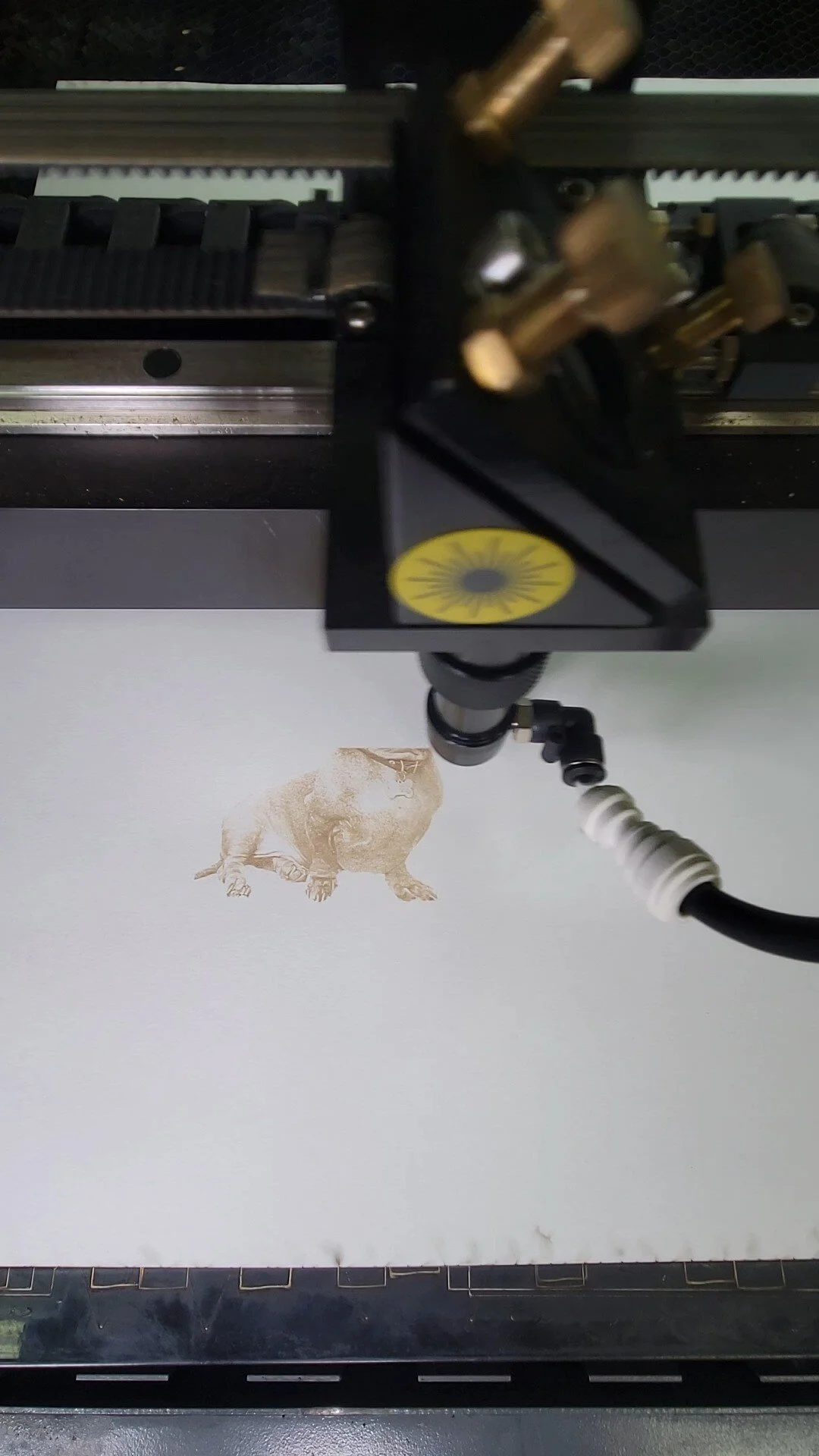

Photographs Transformed: Raster engraving burns images into wood or leather.

Typography in Art: Words and poetry cut into surfaces to convey meaning.

Layered Storytelling: Multiple sheets cut and stacked for depth.

The precision of lasers enhances emotional impact.

Collaborations Between Art and Tech

2025 has seen collaborations between artists and technologists.

Augmented Reality + Laser Art: Digital projections overlay laser-cut structures.

3D Printing + Laser Cutting: Hybrid pieces combine additive and subtractive methods.

AI-Generated Designs: Algorithms create patterns that artists refine and cut.

These partnerships show how technology amplifies, rather than replaces, creativity.

Questions & Answers

Q1: Why are artists turning to laser cutting?

A: It allows them to achieve levels of detail and complexity that hand tools can’t match.

Q2: What materials do artists use most?

A: Wood, acrylic, paper, leather, and metal are popular choices.

Q3: Is laser art only for large studios?

A: No. Desktop machines make laser cutting accessible to independent artists and small studios.

Q4: How does laser cutting change the creative process?

A: It encourages experimentation by making design iterations quick and affordable.

Q5: Can laser art be combined with other media?

A: Absolutely. Artists often mix laser cutting with painting, sculpture,

Acrylic vs. Wood: Which Cuts Better on a CO₂ Laser?

Acrylic vs. Wood: Which Cuts Better on a CO₂ Laser?

Understanding Material Behavior in Laser Cutting

When choosing between acrylic and wood for laser cutting, the difference goes far beyond appearance. Both materials are versatile, easy to source, and laser-safe—but they react very differently under heat. Knowing how each behaves can help you select the best option for your project and ensure professional-quality results.

Cutting Acrylic

Acrylic is one of the most popular materials for CO₂ lasers because it delivers clean, polished edges straight from the machine. When cut with proper settings and airflow, it produces crystal-clear edges with no sanding or flame polishing required.

Advantages:

Smooth, glossy finish right off the laser

Consistent cutting results

Excellent for signage, displays, and lighting projects

Available in a wide range of colors, tints, and thicknesses

Challenges:

Sensitive to heat buildup—requires proper cooling and ventilation

Can warp or melt if the laser speed or power is set incorrectly

Not ideal for engraving deep textures or layered etching

Cutting Wood

Wood offers a warm, organic look that no synthetic material can match. However, it’s less predictable due to natural variations in density, resin, and moisture content. With the right laser settings and material prep, though, wood can produce precise cuts with beautifully dark engraved details.

Advantages:

Natural texture and contrast when engraved

Strong and lightweight

Works well for prototypes, architectural models, and custom decor

Affordable and easily available

Challenges:

Grain and resin can cause inconsistent burning

Prone to smoke staining or scorching on edges

Needs proper masking or finishing for best results

Which Cuts Better Overall?

If you’re aiming for precision, clean edges, and a polished look, acrylic is the clear winner. For organic aesthetics, engraved depth, and natural feel, wood holds the advantage.

The best material depends on your project goals:

Acrylic for signage, displays, lighting, and functional parts

Wood for decor, models, prototypes, and engraving-heavy designs

Professional Laser Cutting for Both

At American Laser Cutter, we work with both materials daily—cutting acrylic, wood, and other laser-safe substrates with industrial precision. Whether you’re creating detailed artwork, signage, or functional components, we optimize settings for clarity, accuracy, and minimal cleanup.

We offer laser cutting services across Los Angeles and provide remote file preparation guidance and nationwide support for larger production orders.

Conclusion

Both acrylic and wood can deliver excellent laser cutting results when processed correctly—but the key is professional setup and calibration.

If you need clean, precise results without guesswork, American Laser Cutter can handle your project from start to finish—on-site in Los Angeles or remotely anywhere in the U.S.

Email americanlaserco@gmail.com or visit americanlaserco.com to request a custom quote.

Laser Cutting for Businesses: How Companies Use It

Laser cutting isn’t just for hobbyists or small workshops. It has become an essential tool for companies across many industries. Whether creating prototypes, customizing packaging, or producing signage, businesses rely on laser cutting for speed, precision, and flexibility. This article explores how companies use laser cutting today and why it’s become so valuable.

Rapid Prototyping

For startups and product designers, speed to market is critical. Laser cutting allows companies to move from concept to physical prototype in hours instead of weeks.

Electronics Enclosures: Acrylic housings for boards and devices.

Mechanical Parts: Test brackets, gears, and mounts.

Packaging Samples: Cardboard mock-ups before mass production.

Because no custom tooling is required, costs stay low and changes are easy.

Custom Signage and Displays

Businesses of all sizes use laser cutting for branding.

Retail Stores: Acrylic letters and logos.

Trade Shows: Portable, eye-catching booth displays.

Corporate Offices: Dimensional signs for lobbies and conference rooms.

The clean edges and precise detail make signage stand out.

Packaging Solutions

Distinctive packaging is vital in a crowded market. Laser cutting enables companies to experiment with structure and style.

Custom Inserts: Foam or cardboard cut to fit products exactly.

Decorative Boxes: Branded patterns etched into packaging.

Short Runs: Cost-effective for limited-edition or promotional items.

This flexibility helps companies test and refine packaging without committing to expensive dies.

Manufacturing and Production

Laser cutting supports production beyond prototypes. Many manufacturers integrate it directly into their workflows.

Sheet Metal Components: Precision parts for machinery and equipment.

Textiles and Leather: Fashion items, upholstery, and accessories.

Plastics and Acrylics: Panels, guards, and structural elements.

Automation and nesting software maximize efficiency in production runs.

Architecture and Interior Design

Architects and designers incorporate laser-cut elements for both function and aesthetics.

Model Making: Scale models with precise details.

Interior Panels: Decorative screens and room dividers.

Furniture Elements: Acrylic or wood details customized to projects.

The ability to execute complex patterns makes laser cutting popular in creative design fields.

Small Businesses and Entrepreneurs

Small businesses benefit from laser cutting as much as large corporations.

E-commerce Shops: Personalized gifts, jewelry, and decor.

Local Makers: Craft products for markets and fairs.

Custom Orders: On-demand production without large inventories.

Makerspaces and rental services lower entry costs, allowing entrepreneurs to compete.

Why Businesses Choose Laser Cutting

Key advantages explain why so many companies adopt laser cutting:

Speed: Faster turnaround compared to traditional manufacturing.

Flexibility: Works with multiple materials and applications.

Scalability: Cost-effective for prototypes and production runs.

Precision: Consistent quality across large batches.

For companies balancing cost, time, and quality, laser cutting often provides the best solution.

Questions & Answers

Q1: Why do businesses use laser cutting instead of traditional methods?

A: It eliminates the need for tooling, reduces waste, and speeds up production.

Q2: Is laser cutting cost-effective for small businesses?

A: Yes. It enables short runs and custom orders without high upfront investment.

Q3: How do large manufacturers use laser cutting?

A: They integrate it into production for sheet metal parts, plastic panels, and custom components.

Q4: Can laser cutting help with packaging?

A: Yes. It’s ideal for custom inserts, branded boxes, and short-run prototypes.

Q5: Do architects use laser cutting?

A: Absolutely. They use it for scale models, decorative panels, and interior details.

Fixing Communication Errors Between Ruida Controllers and LightBurn

Fixing Communication Errors Between Ruida Controllers and LightBurn

When Your Software and Machine Stop Talking

If LightBurn suddenly stops sending jobs to your laser—or your Ruida controller won’t connect, upload, or jog—it’s likely a communication failure. These errors can appear out of nowhere, often after software updates, cable swaps, or network changes. While it might seem like a software glitch, communication breakdowns often point to deeper configuration or hardware issues that require professional attention.

Common Causes of Ruida–LightBurn Connection Problems

Incorrect device settings in LightBurn

Even small mismatches between the machine profile and actual controller type can block communication.Faulty or low-quality USB cable

Ruida controllers are sensitive to interference. Cheap or damaged cables can cause intermittent connection loss, especially on long runs.Network configuration errors

When using Ethernet, IP mismatches or duplicate addresses on the network will prevent discovery or cause dropped connections.Driver or firmware mismatch

After updates, Windows or macOS may replace or block Ruida USB drivers, breaking communication until reinstalled.Corrupted controller memory

Rare, but possible—especially if the machine loses power mid-transfer or if there’s unstable voltage during job upload.

Basic Steps You Can Try

Before calling for service, verify the simplest variables:

Restart both the laser and computer.

Check that LightBurn’s device profile matches your controller type (Ruida).

Test with a different USB cable and port—preferably short and shielded.

If on Ethernet, confirm that both PC and controller are on the same IP range.

Reinstall the FTDI driver from LightBurn’s official support page if USB is still unresponsive.

If these steps don’t restore reliable connection, the issue may be internal—often with the Ruida’s communication board, grounding, or power signal stability.

Why Professional Help Matters

Ruida controllers are robust but tightly integrated. Attempting firmware flashes, voltage adjustments, or internal resets without diagnostic tools can permanently corrupt controller memory.

American Laser Cutter technicians are experienced in troubleshooting both hardware and communication-level faults in Ruida and other controller systems. We can:

Diagnose whether the problem is in LightBurn, the cable, or the controller

Verify grounding and voltage stability in the communication circuit

Restore firmware and clear corrupted controller memory safely

Recalibrate network or USB settings for consistent connectivity

We can perform these diagnostics on-site in Los Angeles or remotely anywhere in the U.S. via screen sharing and guided signal checks.

Conclusion

When LightBurn and your laser stop communicating, it’s rarely the computer’s fault alone—it’s a system issue that requires proper calibration and signal verification.

If your Ruida controller won’t connect or transfer files, American Laser Cutter can help you restore communication—either on-site or remotely anywhere in the country.

Contact americanlaserco@gmail.com for fast, professional support.

Top Laser Cutting Applications in 2025

Laser cutting has evolved into a cornerstone of modern fabrication. What began as an industrial tool for metal processing is now accessible to small businesses, designers, and hobbyists. By 2025, the range of applications continues to grow, driven by better machines, more affordable access, and expanding creative uses. Below are some of the most significant applications where laser cutting shines today.

Signage and Branding

Laser cutting is a favorite in the signage industry. Acrylic letters, logos, and displays are widely produced because lasers cut clean edges and can replicate intricate fonts or shapes perfectly.

Retail Stores: Dimensional signs and wall displays.

Corporate Branding: Logo panels, trade show booth elements.

Wayfinding: Directional signs in buildings, hospitals, and campuses.

The precision of laser cutting ensures consistency across multiple signs, vital for brand recognition.

Prototyping and Product Development

Startups and engineering teams rely heavily on laser cutters for prototypes. Quick turnaround from digital file to physical part means faster testing and refinement.

Product Housing: Acrylic and wood enclosures for electronics.

Packaging: Cardboard prototypes for consumer goods.

Mechanical Parts: Small-scale brackets or alignment jigs.

Compared to traditional tooling, laser cutting reduces costs dramatically in early-stage development.

Architecture and Model Making

Architects and designers use laser cutters to translate CAD models into physical scale representations.

Site Models: Cardboard, foam core, and acrylic layers.

Interior Elements: Patterned panels or room mockups.

Educational Use: Teaching architecture students with hands-on projects.

Fine detail, such as window cutouts or layered facades, is easily achieved.

Fashion and Jewelry

Designers in fashion and jewelry increasingly adopt laser technology.

Textiles: Patterns and lace-like structures cut into fabric.

Leather Goods: Custom belts, wallets, or branded patterns.

Jewelry: Delicate shapes in metals or acrylics, especially with fiber lasers.

The ability to personalize items adds value in competitive consumer markets.

Packaging and Displays

Laser cutting enables businesses to create packaging with precision and creativity.

Custom Boxes: Unique shapes and structural prototypes.

Point-of-Purchase Displays: Branded acrylic or wood stands.

Event Decor: Cardboard or plywood signage and props.

With e-commerce growth, distinctive packaging has become a powerful branding tool.

Education and Makerspaces

Schools, universities, and community makerspaces rely on laser cutters for teaching STEM concepts.

Engineering Classes: Students build robots, gears, or prototypes.

Art and Design: Creative engraving projects.

Workshops: Community spaces allow access to high-end fabrication for personal projects.

This accessibility fosters innovation at grassroots levels.

Industrial and Automotive

Laser cutting remains important in industrial settings, particularly with metals.

Sheet Metal Fabrication: Precision components for machinery.

Automotive: Brackets, panels, and specialty parts.

Aerospace: Lightweight, precise metal components.

High-power fiber lasers enable cutting thicker metals more efficiently than ever before.

Home and Hobby Projects

Desktop laser cutters are now affordable enough for hobbyists.

Home Decor: Wall art, coasters, lamps.

Crafts: Personalized gifts, puzzles, ornaments.

Entrepreneurial Ventures: Small shops selling laser-cut goods online.

This democratization means laser cutting is no longer limited to industrial spaces.

Future Outlook

In 2025 and beyond, AI-driven optimization, improved nesting software, and sustainability trends continue to expand applications. Reduced waste, faster turnaround, and integration with digital design tools make laser cutting more relevant each year.

Questions & Answers

Q1: What industries use laser cutting most in 2025?

A: Signage, prototyping, architecture, fashion, packaging, education, and manufacturing all rely heavily on laser cutting.

Q2: Why is laser cutting popular for prototypes?

A: It offers fast turnaround, low setup costs, and the ability to make multiple design iterations quickly.

Q3: Can laser cutting be used in fashion?

A: Yes, it is widely used to cut patterns in fabric and engrave designs on leather.

Q4: How do schools use laser cutters?

A: They help students learn engineering, design, and creative problem solving by making real-world projects.

Q5: Is laser cutting mostly for professionals?

A: No. Desktop machines and makerspaces make it accessible for hobbyists and small businesses as well.

Laser Cutting in Aerospace Applications — Precision Above All

Aerospace manufacturing demands the highest levels of precision, safety, and performance. Every component, from structural panels to interior details, must meet strict standards. In 2025, laser cutting plays a critical role in meeting these demands. Its ability to cut complex shapes with minimal waste makes it indispensable in aircraft and spacecraft production.

Structural Components

Aircraft rely on strong but lightweight materials. Laser cutting handles these efficiently.

Aluminum Alloys: Widely used for fuselage panels and brackets.

Titanium: Strong, heat-resistant material cut with fiber lasers.

Composites: Laser systems adapt to layered structures without excessive damage.

Precision ensures parts fit seamlessly during assembly.

Engine and Mechanical Parts

Engines require components with tight tolerances.

Heat Shields: Thin metal sheets cut for thermal protection.

Turbine Components: Intricate designs cut into specialized alloys.

Brackets and Supports: Consistency is critical for safety.

Laser cutting minimizes thermal distortion compared to older methods.

Interior and Cabin Design

Beyond mechanics, lasers enhance the passenger experience.

Seating Upholstery: Leather engraved with logos or patterns.

Lighting Panels: Decorative cutouts for modern cabin aesthetics.

Partitions: Lightweight dividers cut from composites or plastics.

Airlines use customization to differentiate passenger spaces.

Prototyping and R&D

Aerospace companies invest heavily in prototyping before committing to production.

Rapid Prototypes: Engineers test aerodynamic designs quickly.

Material Trials: Different alloys and composites evaluated with laser cuts.

Iterative Design: Changes made rapidly without tooling delays.

This reduces development cycles for new aircraft models.

Safety and Standards

Aerospace regulations are strict, and laser cutting supports compliance.

Non-Contact Cutting: Reduces contamination risk.

Repeatability: Ensures identical results across batches.

Traceability: Digital records link cuts directly to design files.

These factors contribute to quality assurance and certification processes.

Environmental Benefits

Efficiency and sustainability are priorities for aerospace.

Lightweighting: Cutting supports new designs that reduce fuel consumption.

Material Efficiency: AI-driven nesting minimizes scrap.

Cleaner Energy Use: Fiber lasers cut faster with less power.

This aligns with the industry’s goal of lowering carbon footprints.

Questions & Answers

Q1: Why is laser cutting important in aerospace?

A: It provides precision, efficiency, and flexibility needed for high-performance parts.

Q2: What materials are commonly laser cut in aircraft?

A: Aluminum, titanium, composites, and specialty alloys.

Q3: Can lasers handle aerospace-grade composites?

A: Yes, modern systems adapt to layered materials with minimal damage.

Q4: How does laser cutting improve safety in aerospace?

A: It ensures consistent, contamination-free parts that meet strict tolerances.

Q5: Does laser cutting help reduce aircraft emissions?

A: Indirectly, by enabling lightweight designs that improve fuel efficiency.

Troubleshooting Laser Tube Ignition Failures

Troubleshooting Laser Tube Ignition Failures

When Your CO₂ Laser Won’t Fire

Few things are more frustrating than a laser cutter that won’t fire at all. You hit “Start,” hear the fans and coolant running, but the laser tube stays dark. Tube ignition failure is a common issue—and while it might look like a total breakdown, it usually points to a specific electrical or safety circuit fault that needs professional attention.

What Causes Ignition Failure

High-voltage power supply failure

CO₂ tubes need 20,000 volts or more to start the arc inside the glass. If the power supply isn’t delivering the right voltage or can’t maintain stability, the tube won’t ignite.Faulty laser enable or interlock wiring

A disconnected safety interlock, door sensor, or loose cable can interrupt the ignition sequence entirely.Weak or expired laser tube

Tubes naturally lose gas pressure and excitation ability over time. A worn tube may still flicker or pulse weakly before fully dying.Mainboard or controller signal failure

The firing signal from your control board might not be reaching the power supply, especially after power surges or cable damage.Grounding or polarity issues

Incorrect grounding or reversed polarity can block ignition and damage internal components.

What You Can Check Safely

Without opening the chassis, verify:

Your cooling system is active and circulating.

The main power switch and laser enable key are both on.

There are no interlock or door errors showing on the control panel.

You can hear the high-voltage power supply engage (a faint static click or hum) when attempting to fire.

If all systems appear normal but there’s still no light inside the tube, stop there—anything further requires proper safety gear and diagnostic tools.

Why Professional Testing Is Essential

Inside the laser’s high-voltage system, current can exceed 20,000 volts—enough to arc through insulation or cause serious injury. Randomly swapping components to “see what fixes it” can blow the power supply or controller, doubling repair costs.

American Laser Cutter technicians isolate each section of the circuit, measuring voltage, signal, and ground continuity safely. We test:

Laser enable circuits and interlocks

Power supply output and stability

Tube continuity and gas integrity

Controller signal voltage consistency

With these readings, we can identify whether the problem lies in the tube, power system, or logic control—and restore proper firing without unnecessary replacements.

Conclusion

Ignition problems can look catastrophic, but they’re usually electrical—not fatal. Proper diagnosis prevents wasted parts and downtime.

If your CO₂ laser isn’t firing or showing power fluctuations, American Laser Cutter can diagnose and repair the issue on-site or remotely anywhere in the U.S.

Email americanlaserco@gmail.com to schedule expert service and get your laser cutting again.

Why You Shouldn’t Realign Your Laser Beam Yourself

Why You Shouldn’t Realign Your Laser Beam Yourself

The Risk Behind “Simple” Laser Alignment

It’s common for laser owners to assume beam alignment is a quick fix—just a few mirror tweaks and it’s back in business. Unfortunately, that’s not how it works. Realignment is one of the most delicate and complex procedures in laser repair. A minor misstep can throw the entire optical path off balance, cause severe power loss, or even damage components permanently.

If your laser has started cutting unevenly or leaving inconsistent burn marks, alignment is likely the issue—but this is not something to attempt without proper calibration tools and experience.

Why Alignment Is So Difficult

Three mirrors, one beam, zero room for error

Every mirror must reflect the laser precisely onto the next one. A fraction of a millimeter off at mirror one can translate into major misalignment at the head.Thermal drift

As the laser warms up, slight frame expansion can shift optical geometry. Aligning “cold” can make things worse once the machine heats during use.Optical contamination

Even touching the lens or mirrors during an alignment attempt can deposit oils that reduce beam intensity and burn the coating.High voltage and beam exposure risks

Firing test pulses without protection or proper enclosures can cause burns, fires, or damage to nearby components.

Signs Your Machine Needs Alignment

The laser cuts fine in one corner but fades in another.

Engraving depth varies across the same sheet.

You hear arcing or see flashing at the laser head.

Your mirrors or lens appear burnt or discolored.

These are strong indicators of misalignment—but also of potential underlying issues like frame warping or loose mounts.

Why Professional Alignment Matters

At American Laser Cutter, alignment isn’t guesswork—it’s precision measurement. Our technicians use calibrated alignment targets, verified optical meters, and safe beam detection to restore perfect mirror geometry. We also inspect for other causes, like:

Damaged mirror mounts or brackets

Frame or gantry distortion

Tube positioning errors

Optical path contamination

Every alignment job includes a complete test of beam focus and travel across the bed to ensure uniform power at every corner.

Conclusion

Laser alignment is one of the most important—and most misunderstood—maintenance tasks. Without the proper tools, it’s nearly impossible to achieve true accuracy or diagnose related issues.

If your laser is misaligned or producing uneven results, American Laser Cutter can professionally realign and calibrate your system, either on-site or remotely anywhere in the U.S.

Contact americanlaserco@gmail.com for expert service and reliable results.

The Most Unusual Materials Ever Laser Cut (and Why Some Worked)

The Most Unusual Materials Ever Laser Cut (and Why Some Worked)

Laser cutting is often associated with wood, acrylic, and metals. But innovators around the world have experimented with far stranger materials. Some results are impressive, while others serve as cautionary tales. Exploring these unusual experiments highlights both the versatility and the limits of laser technology.

Chocolate and Confectionery

Believe it or not, chocolate can be laser cut. Bakeries and food designers have used low-power CO₂ lasers to etch designs into chocolate bars and even cut shapes into thin sheets.

Why It Works: Chocolate absorbs laser energy easily without requiring much power.

Challenges: Heat can melt or discolor the chocolate if not carefully controlled.

Applications: Custom logos, edible decorations, and artistic desserts.

Leaves and Natural Fibers

Artists have used lasers to cut patterns into dried leaves, flowers, and other plant matter.

Why It Works: Organic material vaporizes cleanly with low power.

Challenges: Fragility makes it easy to burn or tear.

Applications: Botanical art, jewelry, and eco-friendly decor.

Denim and Everyday Clothing

Fashion designers experiment with denim laser cutting to create distressed textures or intricate lace-like patterns.

Why It Works: Lasers burn away surface fibers for controlled fading or patterns.

Challenges: Overheating can weaken fabric.

Applications: Custom jeans, jackets, and fashion statements.

Edible Seaweed Sheets

Some chefs use lasers on nori (seaweed sheets) to make artistic sushi wraps.

Why It Works: Thin, dry sheets cut easily with low power.

Challenges: Fragility and flammability.

Applications: Creative food presentation in high-end restaurants.

Stone and Slate

While not unusual in industrial contexts, cutting or etching stone surprises many. Lasers don’t cut through thick stone but can engrave the surface with precision.

Why It Works: High-power lasers chip away at the surface.

Challenges: Cannot achieve deep cuts; limited to marking or engraving.

Applications: Custom coasters, tiles, plaques.

Paper-Thin Metals from Everyday Items

Artists have repurposed soda cans and aluminum foil for laser projects.

Why It Works: Thin metals cut cleanly with fiber lasers.

Challenges: Reflectivity requires careful setup to avoid damaging the machine.

Applications: Jewelry, small sculptures, decorative items.

Materials That Failed

Some experiments showed why safety matters:

PVC: Releases toxic chlorine gas.

ABS: Produces cyanide fumes.

Polycarbonate: Burns and discolors instead of cutting.

These attempts serve as warnings about checking material safety first.

Questions & Answers

Q1: Can lasers really cut food like chocolate or seaweed?

A: Yes, with low power settings and careful control, food can be engraved or cut for decorative purposes.

Q2: What’s the weirdest successful laser-cut material?

A: Many say chocolate or seaweed, since both have been used in high-end culinary design.

Q3: Why do some materials fail with lasers?

A: Certain plastics release toxic fumes or resist cutting due to their chemical makeup.

Q4: Are unusual materials safe to experiment with?

A: Only if verified safe. Always avoid PVC, ABS, fiberglass, and other toxic materials.

Q5: What does this say about laser cutting’s potential?

A: It shows that lasers are more versatile than most people realize — not just for industrial use but also for art, fashion, and food.

Why Your Laser Cutter Is Losing Power (and How to Test It)

Why Your Laser Cutter Is Losing Power (and How to Test It)

Understanding Power Loss in CO₂ Lasers

If your laser cutter is taking longer to cut, struggling with materials it used to handle easily, or producing inconsistent burns, you’re likely dealing with power degradation. It’s one of the most common and frustrating issues laser owners face—especially with older CO₂ systems.

Laser power loss can develop gradually or suddenly, depending on several underlying causes. Recognizing which type you’re dealing with is key to solving it quickly.

Common Causes of Power Loss

Aging or worn-out laser tube

CO₂ laser tubes lose efficiency over time as the gas mixture weakens. Even if your power supply is fine, a weak tube can cause your machine to cut inconsistently.Misaligned optics

Mirrors or lenses that are even slightly out of alignment can scatter energy and reduce beam strength at the cutting point.Dirty mirrors or lenses

Dust, smoke, or residue buildup can block or diffuse light energy, lowering output dramatically.Power supply or wiring faults

Faulty cables, cracked insulation, or inconsistent voltage delivery can mimic tube problems.Cooling system issues

Poor water flow or overheating can cause power dips and accelerate tube wear.

How to Test for Power Loss

If your machine suddenly stops performing like it used to, check:

Beam output consistency: Fire test pulses at identical settings and compare burn marks.

Cut comparison: Try the same file and material that used to work well.

Voltage reading: If you have proper training and tools, check output at the power supply (otherwise, stop—this involves high voltage).

If these tests confirm your laser isn’t firing at full strength, it’s time for a professional diagnosis.

Why Professional Diagnosis Matters

Most cases of power loss are not caused by a single issue. Tubes, mirrors, power supplies, and controllers all interact, and fixing one without inspecting the others can waste money and risk further damage.

At American Laser Cutter, we use diagnostic tools to:

Measure true tube output and voltage stability

Identify alignment drift and optical loss

Verify power supply integrity

Inspect cooling and exhaust systems for wear

We provide full-service on-site repairs in the Los Angeles area and remote diagnostic support nationwide. Whether your system just needs recalibration or a full component replacement, our technicians can restore your laser to full performance.

Conclusion

Loss of power doesn’t mean your laser’s life is over. With expert testing and precision repair, most machines can return to peak output quickly.

If your CO₂ laser has lost power or cutting accuracy, American Laser Cutter can help—either on-site or remotely anywhere in the U.S.

Contact americanlaserco@gmail.com to schedule a diagnostic session today.

Laser Cutting Services — Los Angeles

Laser Cutting Services — Los Angeles

Clean, Accurate, and Professional Results

American Laser Cutter provides precision CO₂ laser cutting for creative professionals, engineers, and businesses throughout Los Angeles. Every project is cut on large-format industrial machines designed for accuracy and repeatability, producing clean edges and reliable results every time.

Capabilities

Cutting size: up to 4’×5’

Laser power: 100W–180W CO₂ systems

Accepted files: AI, DXF, PDF

Supported materials: acrylic, birch plywood, paperboard, and more laser-safe options

Edge finish: smooth, sealed, and production-ready

Clients can provide their own material or purchase from our in-house supply.

How It Works

Send your file and project details for a custom quote.

Approve your estimate and confirm material choice.

Production begins at our Downtown Los Angeles shop.

Pickup or shipping arranged once complete.

Turnaround averages 3–5 business days, with faster options available upon request.

Advantages

Tight tolerances: Clean cuts and consistent accuracy.

Scalable output: From single prototypes to full production runs.

Fast communication: Speak directly with our cutting team.

Local service: Centrally located for quick turnaround and delivery.

Best For

Product prototypes

Custom signage

Displays and enclosures

Architectural models

Decorative and branded pieces

Request a Quote

Attach your AI, DXF, or PDF file and email americanlaserco@gmail.com, or visit americanlaserco.com to get started with your next laser cutting project.

Laser Cutting Services in Downtown Los Angeles

Laser Cutting Services in Downtown Los Angeles

Precision Results for Every Project

American Laser Cutter provides high-accuracy CO₂ laser cutting for clients who need clean edges, exact tolerances, and professional consistency. We handle everything from individual prototypes to full production runs using large-format industrial systems operated in-house.

Capabilities

Cutting size: up to 4’×5’

Power range: 100–180 watts

Accepted file types: AI, DXF, PDF

Supported materials: acrylic, birch, and other verified laser-safe options

Edge quality: polished, precise, and production-ready

Clients may bring their own material or choose from in-stock options.

Process

Submit your vector file by email for a quote.

Confirm your project details — material, size, and quantity.

Approve and pay to start production.

Pickup or shipping arranged when your order is complete.

Turnaround averages 3–5 business days, with rush options available.

Benefits

Exact detail: Consistent, repeatable accuracy on every cut.

Flexible scale: Perfect for prototypes, one-offs, or bulk production.

Fast communication: Direct with technicians, not a call center.

Central location: Convenient pickup in Downtown Los Angeles.

Ideal For

Product and packaging designers

Architects and builders

Artists and fabricators

Manufacturers and small businesses

Get a Quote

Send your project details and file to americanlaserco@gmail.com or visit americanlaserco.com to request a quote for your next laser cutting job.

Laser Cutting Services for Los Angeles Businesses and Creators

Laser Cutting Services for Los Angeles Businesses and Creators

High-Precision Cutting, Local Expertise

American Laser Cutter delivers professional CO₂ laser cutting for clients across Los Angeles who demand precision and consistency. From one-off prototypes to ongoing production, every cut is handled on commercial-grade systems built for accuracy and repeatability.

Service Capabilities

Cutting size: up to 4’×5’

Power range: 100W–180W CO₂ lasers

Accepted files: AI, DXF, or PDF

Supported materials: acrylic, birch, and other verified laser-safe types

Finish: clean, sealed edges ready for use or assembly

Clients are welcome to supply their own material or purchase from available stock.

How It Works

Send your vector file with project details.

Receive a custom quote based on material and cutting time.

Confirm your order to begin production.

Pickup or shipping once your job is complete.

Standard turnaround is 3–5 business days. Rush options (1–2 days) are available when needed.

Benefits

Consistent accuracy: Industrial systems deliver smooth, repeatable results.

Scalable workflow: Ideal for both creative studios and manufacturing runs.

Transparent pricing: Quotes based on time and material only.

Los Angeles location: Centrally positioned for fast service and delivery.

Common Applications

Product prototyping and short runs

Architectural mockups

Retail and event signage

Art and design projects

Custom packaging components

Get a Quote

Email americanlaserco@gmail.com with your file and project details, or visit americanlaserco.com to request a quote for your next laser cutting job.

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)